Remote automatic sampling and centralized dispatching method for ash

A centralized dispatching and ash-powdering technology, which is applied in sampling, sampling device, program control, etc., can solve the problems of high labor intensity, easy dust spraying, and few sampling personnel, so as to improve the working environment of personnel, reduce work intensity, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

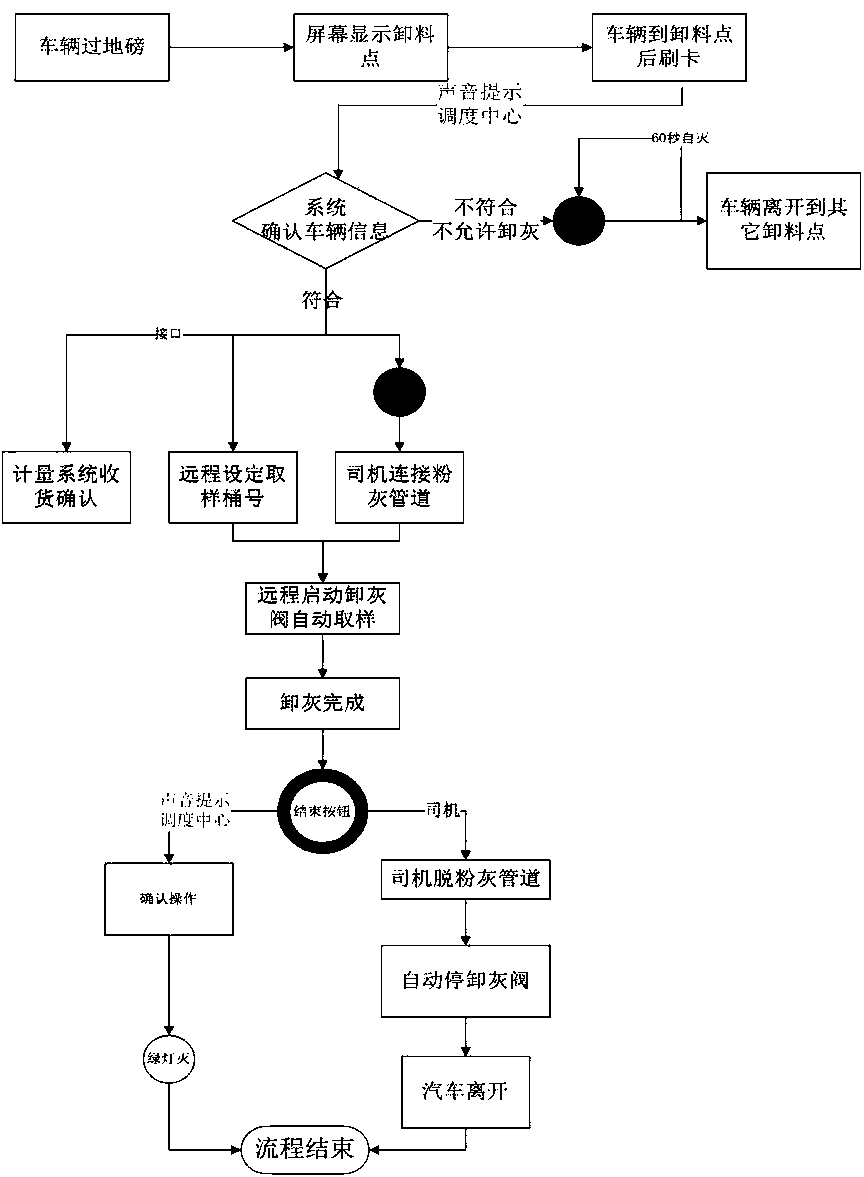

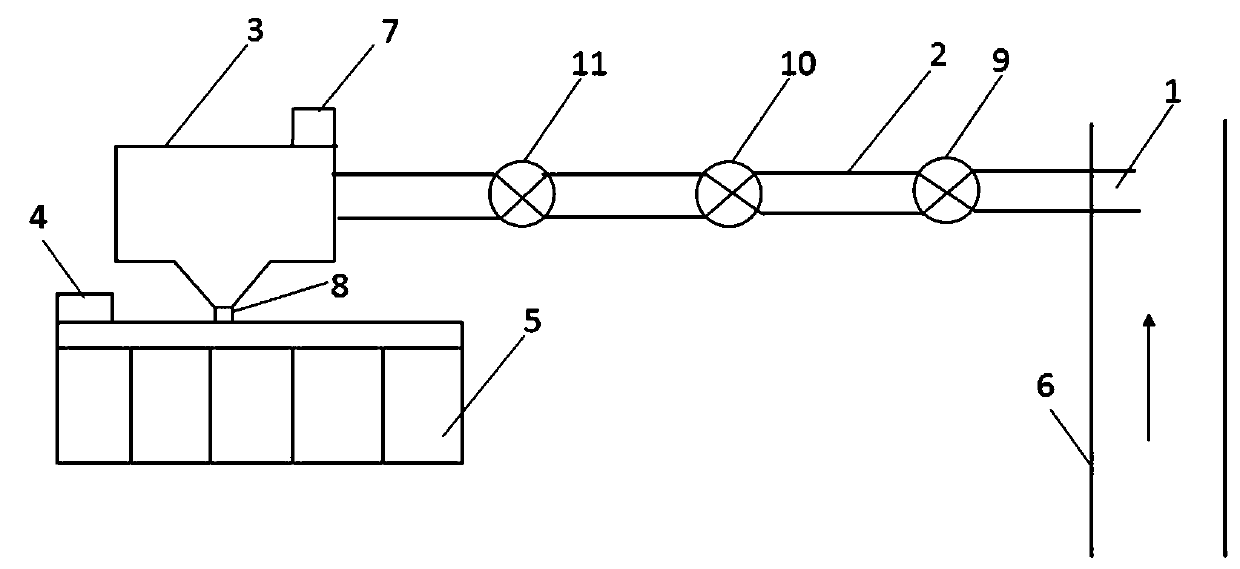

[0019] The present invention proposes a centralized scheduling method for remote automatic sampling of fly ash, such as figure 1 shown, including the following steps:

[0020] Step 1: The powder ash coke tank truck passes the weighbridge to measure the gross weight of the coke tank truck, automatically assigns the unloading point according to the height of the powder ash material in the warehouse, and automatically displays the unloading point on the electronic screen at the weighbridge; drive the powder ash coke tank truck to the designated unloading point Material point, and use the vehicle pass to swipe the card on the card machine; determine the sampling amount according to the gross weight of the coke tanker.

[0021] Step 2: The card reading device judges whether the information of the coke tank car is consistent; if the card information is not in conformity, the red indicator light is on, and the card reader voice prompts that the unloading address is incorrect, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com