Monitoring system applied to power grid production equipment

A technology of production equipment and monitoring system, applied in the field of monitoring system of power grid production equipment, to achieve the effect of improving stability, improving efficiency of defect elimination, and reasonable scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

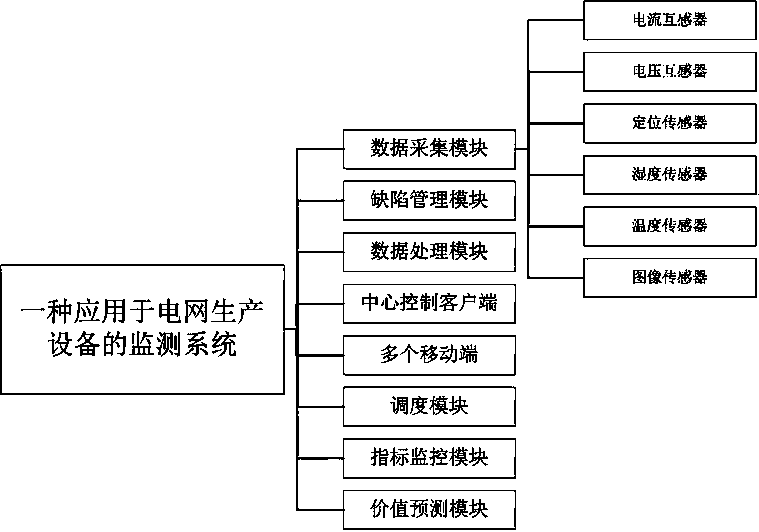

[0033] Such as figure 1 As shown, this embodiment discloses a monitoring system applied to power grid production equipment, including:

[0034] (1) The data acquisition module is used to collect in real time the basic data reflecting the state of production equipment, the distribution data of production equipment, and the data of the line where the production equipment is located, and judge whether the production equipment is in a defect state and the defect type under the defect state based on the basic data , defect level; the basic data is the data reflecting the status of the production equipment in the operation and maintenance phase of the production equipment, including the defect of the production equipment body, the change of the distance to the ground of the connection line of the production equipment, the load change of the connection line of the production equipment, the relative The location changes on the ground, etc., the distribution data of production equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com