Heat insulation protection cable

A cable and internal protection technology, applied in the field of heat insulation and protection cables, can solve the problems of affecting the service life of cables, general heat insulation effect, and spontaneous combustion of cables, etc., and achieve the effect of improving anti-corrosion ability, good safety, and improving heat insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

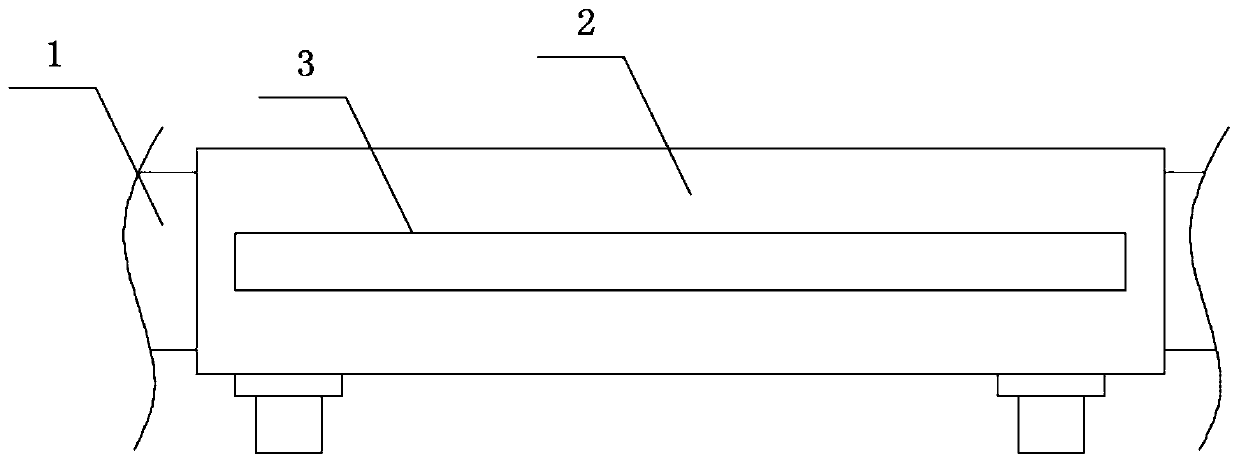

[0037] see Figure 1-5 , the present invention provides a technical solution: a thermal insulation protection cable, comprising: a cable 1 and a thermal insulation fixing mechanism 2 .

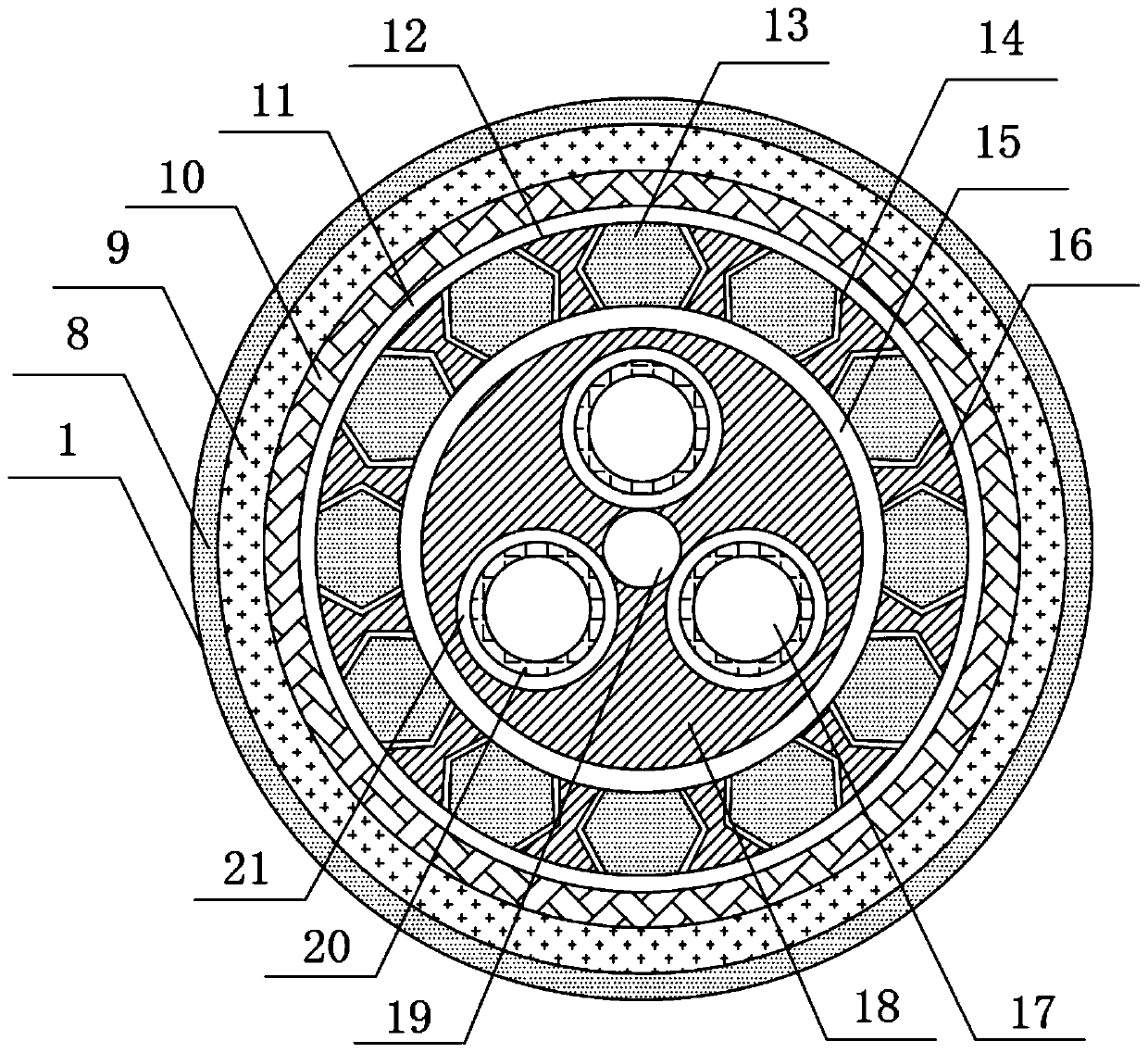

[0038] Wherein, the cable 1 includes an outer protective layer 8, an inner protective layer 15 and a wire 17, the wires 17 are provided with three wires, the outer protective layer 8 is located outside the inner protective layer 15, and three of the wires 17 are located in the inner protective layer. Inside the layer 15, a flame-retardant layer 9 is fixedly installed on the inner wall of the outer protective layer 8, a heat-insulating layer 10 is fixedly installed on the inner wall of the flame-retardant layer 9, and a waterproof insulating layer 11 is fixedly installed on the inner wall of the heat-insulating layer 10, so A fire extinguishing chamber 12 is arranged between the waterproof insulating layer 11 and the inner protective layer 15, and steel sheets 14 are fixedly installed inside th...

Embodiment 2

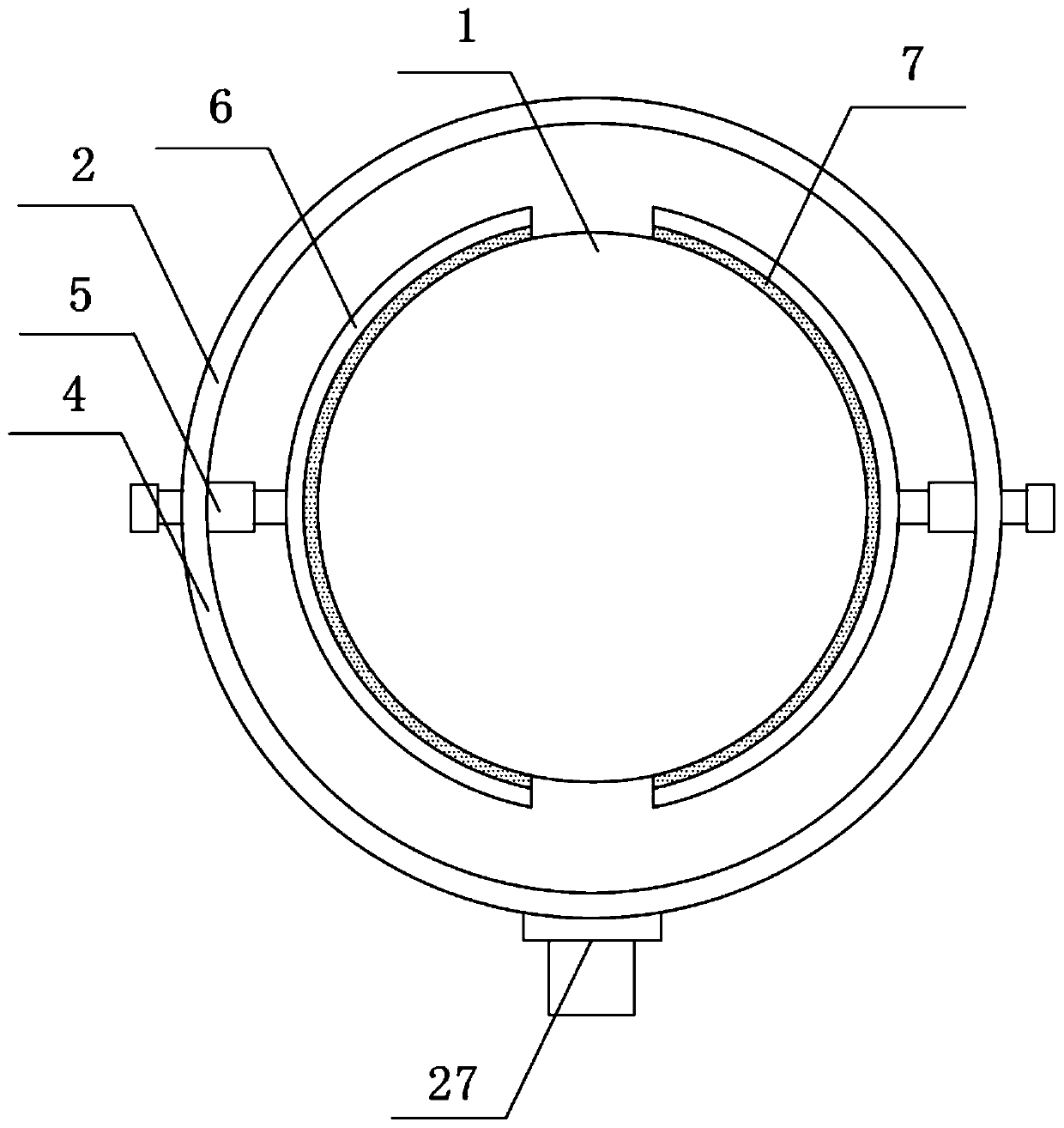

[0056] see figure 1 , figure 2 and Figure 5 , the present invention provides a technical solution: a heat insulation protection cable, the heat insulation fixing mechanism 2 includes a fixing sleeve 4, and a clamping mechanism 5 is fixedly installed on both sides of the inner wall of the fixing sleeve 4, and the clamping mechanism 5 is set There are two groups, the clamping mechanism 5 includes a connecting rod 23 and a sleeve 24, the connecting rod 23 is slidably installed inside the sleeve 24, and the outer surface of the connecting rod 23 located inside the sleeve 24 is covered with a pressure plate 26 And spring 25, the sliding connection between the pressure plate 26 and the sleeve 24, the spring 25 is located at one end of the pressure plate 26, one end of the connecting rod 23 extends to the inside of the fixed sleeve 4 and is fixedly installed with the clamping plate 6, the connection The other end of the rod 23 extends to the outside of the fixed sleeve 4 and is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com