Cooling system for plant growth lamp of planting container

A plant growth lamp and container technology, applied in the field of cooling system, can solve the problems of power consumption, unreasonable cooling method, and reduce the airtightness of the container planting area, so as to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

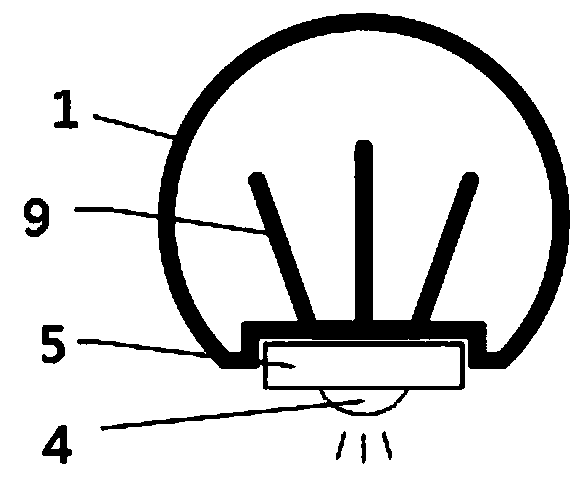

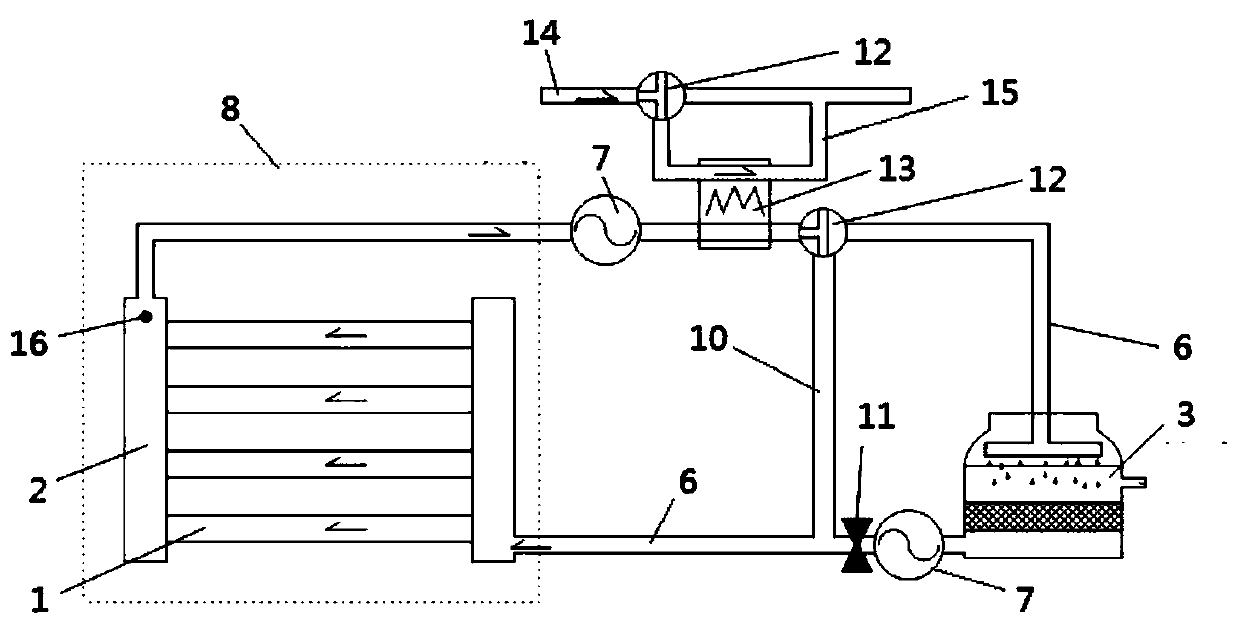

[0015] refer to figure 1 and figure 2 , this embodiment provides a cooling system for planting container plant growth lamps, which is characterized in that it includes a tubular heat dissipation profile 1, a collecting pipe 2 and a cooling tower 3, and the tubular heat dissipation profile 1 is along the length direction of the growth light bar 4 Fitted and fixed on the growth lamp base material 5, the growth lamp base material 5 on the back of each growth light bar 4 in the container planting area 8 is fitted and fixedly connected with a tubular heat dissipation profile 1, and the tubular heat dissipation profile 1 has better thermal conductivity Made of different materials, such as copper, aluminum and other materials, the inner side of the tubular heat dissipation profile 1 corresponding to the base material 5 of the growth lamp is also fixedly connected with the heat dissipation efficiency column 9, so that the base material 5 of the growth lamp passes through the tubular ...

Embodiment 2

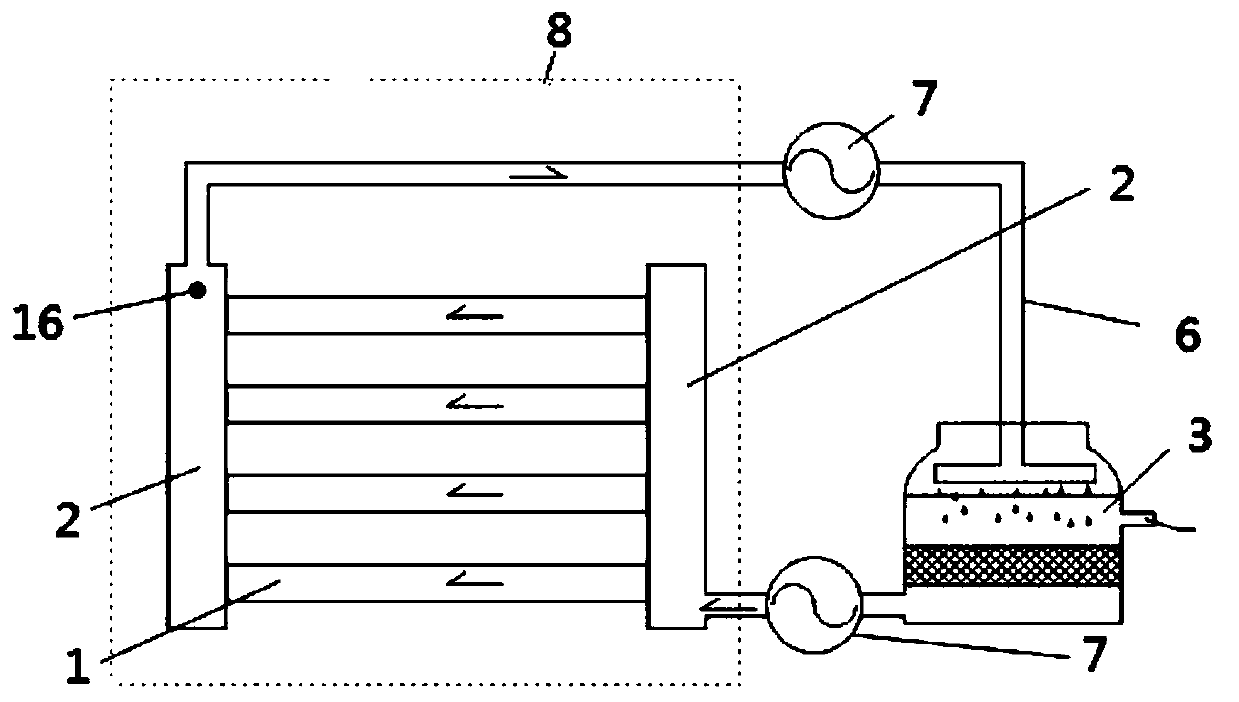

[0017] refer to figure 2 and image 3 , this embodiment provides a cooling system for planting container plant growth lamps, which is characterized in that it includes a tubular heat dissipation profile 1, a collecting pipe 2 and a cooling tower 3, and the tubular heat dissipation profile 1 is along the length direction of the growth light bar 4 Fitted and fixed on the growth lamp base material 5, the growth lamp base material 5 on the back of each growth light bar 4 in the container planting area 8 is fitted and fixedly connected with a tubular heat dissipation profile 1, and the tubular heat dissipation profile 1 has better thermal conductivity Made of different materials, such as copper, aluminum and other materials, the inner side of the tubular heat dissipation profile 1 corresponding to the base material 5 of the growth lamp is also fixedly connected with the heat dissipation efficiency column 9, so that the base material 5 of the growth lamp passes through the tubular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com