Dough pressing and portioning device and automatic noodle making machine

A technology of driving device and pressing roller, which is applied in the direction of dough mixer, dough forming machinery or equipment, dough forming and cutting equipment, etc., which can solve the problem of consuming a lot of physical strength and time, unable to guarantee the consistency of noodle shape and taste, and large labor load, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

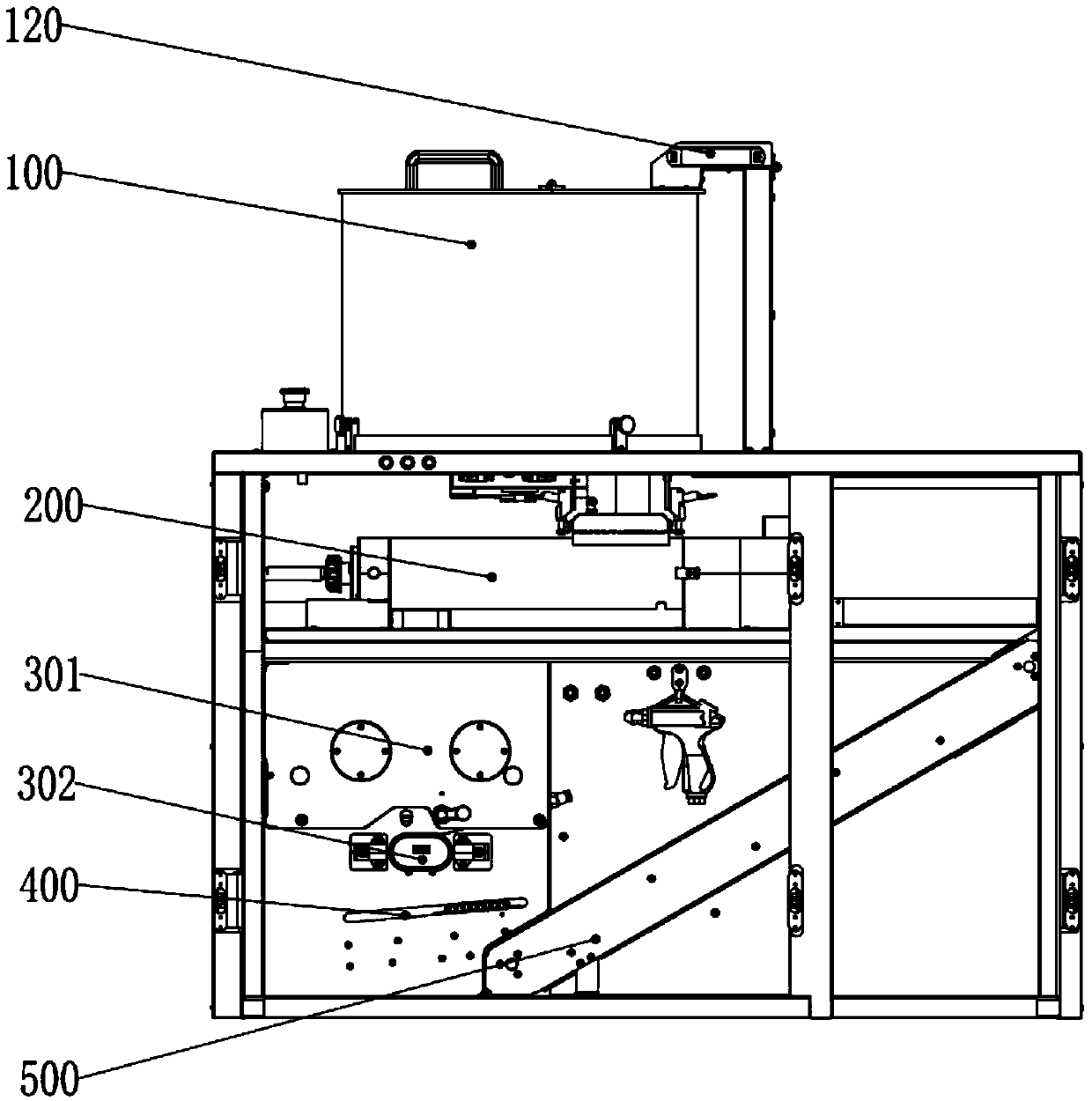

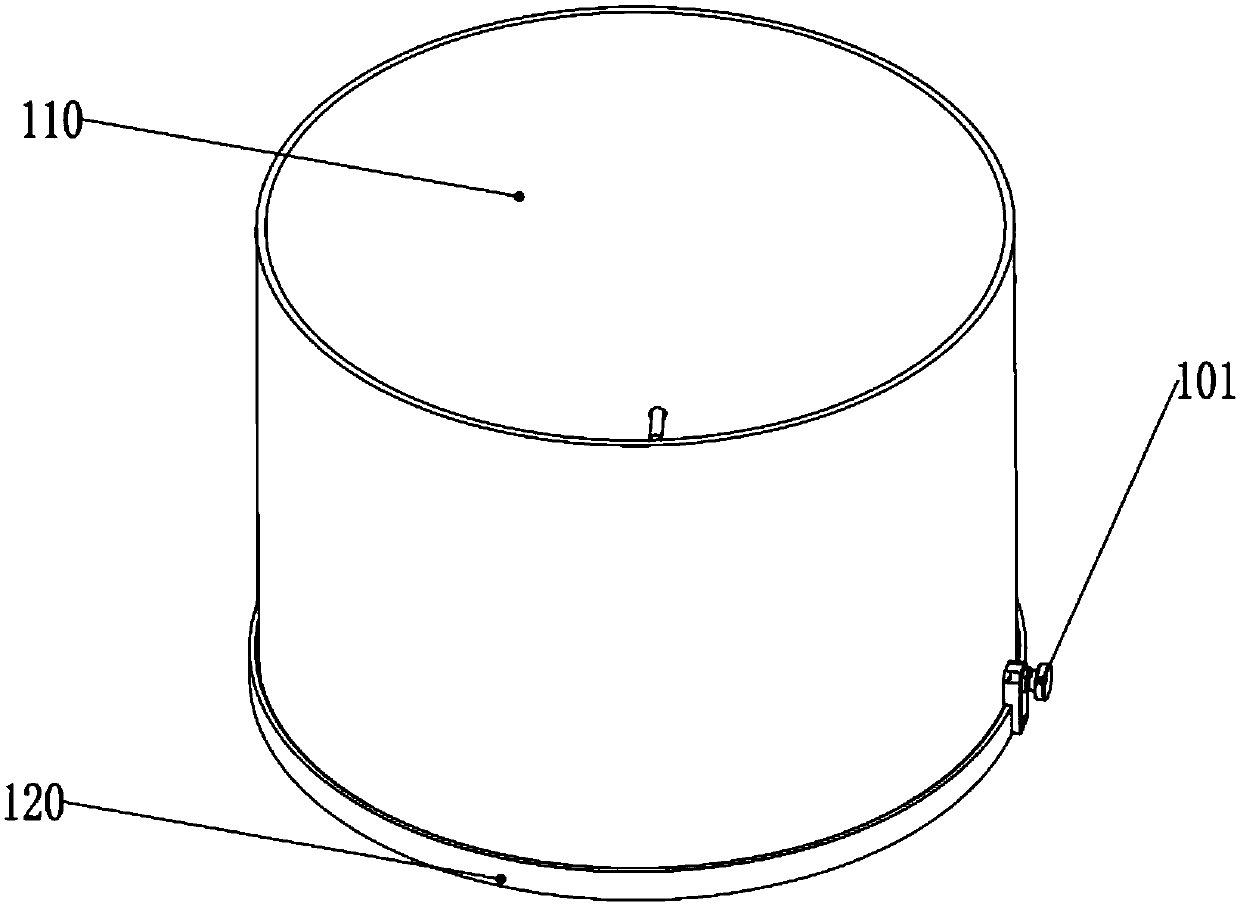

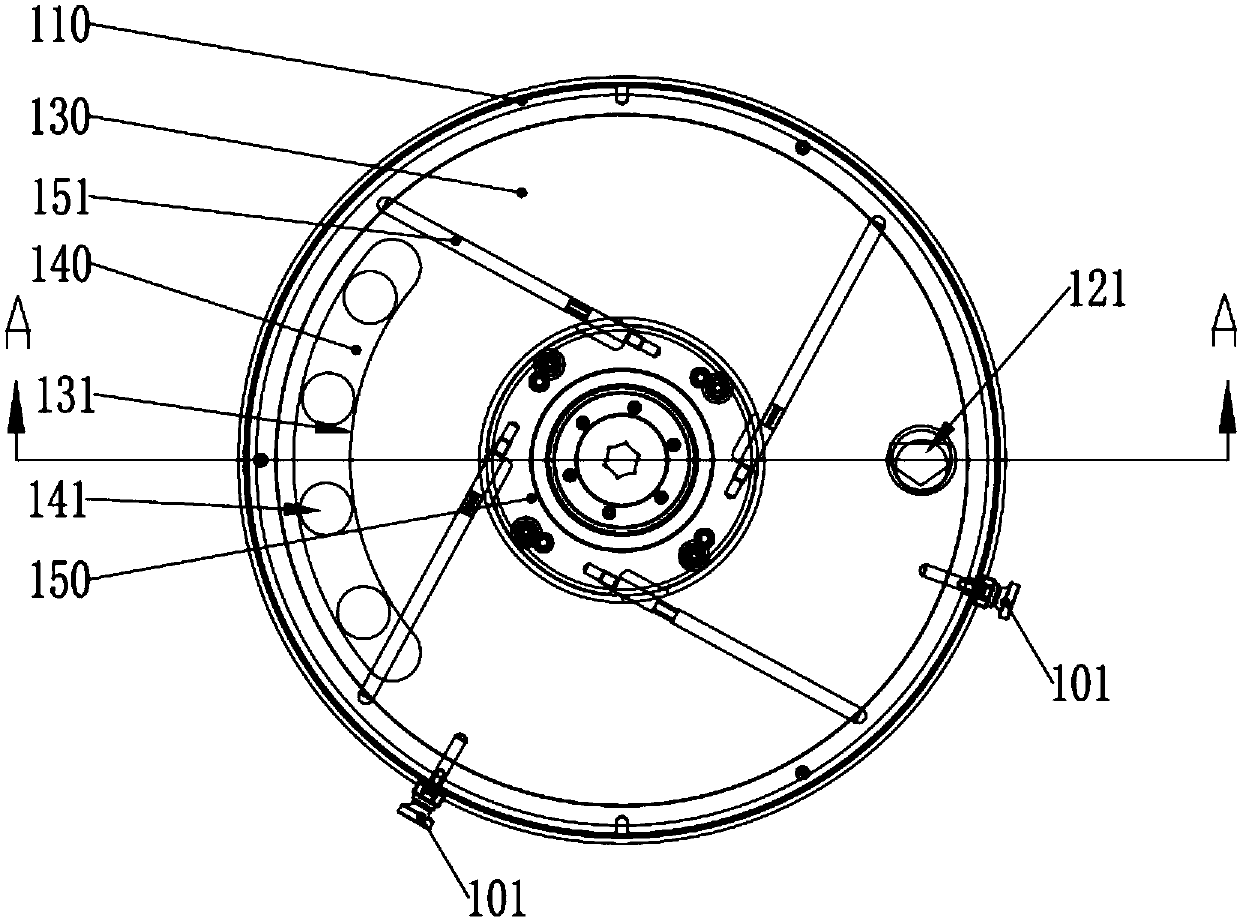

[0026] Such as figure 1 Shown, a kind of automatic noodle making machine, it comprises successively from top to bottom: flour uniform quantitative feeding device 100, water surface uniform mixing device 200, pressing noodle portioning device, automatic noodle setting device 400 and stepping conveyor belt 500; Said flour uniform quantitative feeding device 100 comprises a bucket 110 and a stirring mechanism in the bucket 110, said bucket 110 upper end is provided with a charging port, and the lower end is provided with a feeding hole 121; said water surface uniform mixing device 200 is provided with The water inlet 242 and the powder inlet 241, the bottom is provided with a flocculation outlet; the pressing surface portioning device includes: a pressing surface roller assembly 301 and a noodle cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com