A kind of aluminum alloy formwork and its installation method

An aluminum alloy formwork and formwork technology, which is applied to formwork/formwork components, formwork/formwork/work frame connectors, and formwork processing, etc., can solve problems such as poor splicing efficiency, reduce the number of fixings, The effect of reducing splicing time and splicing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

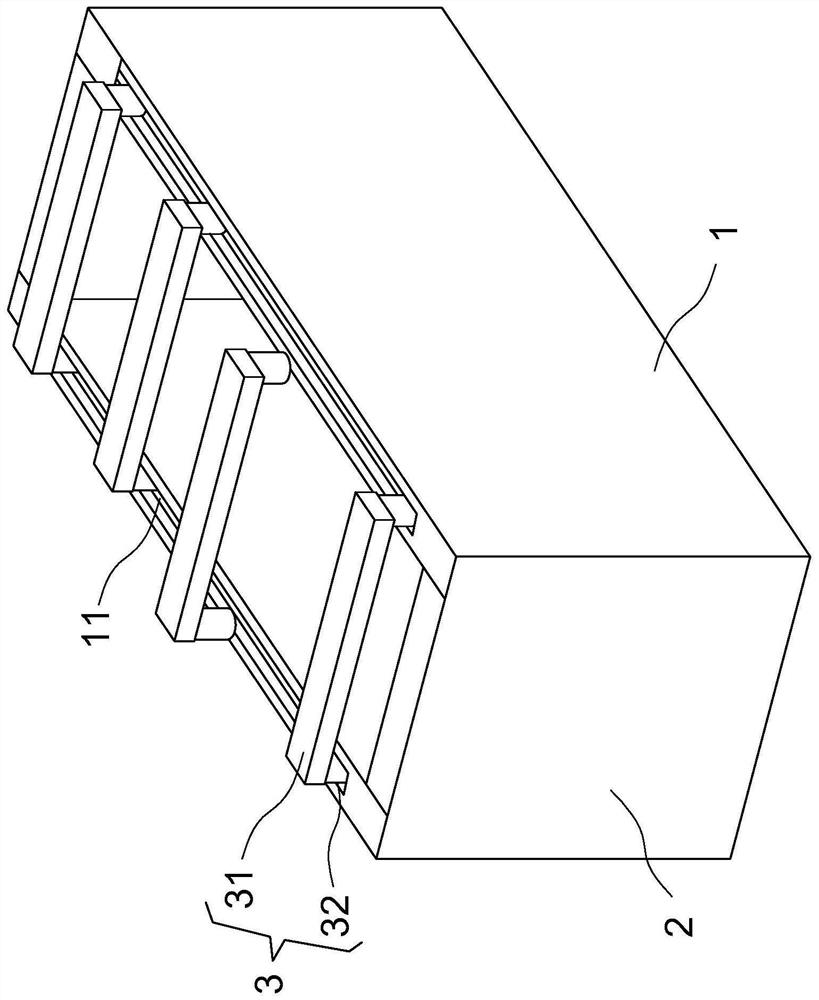

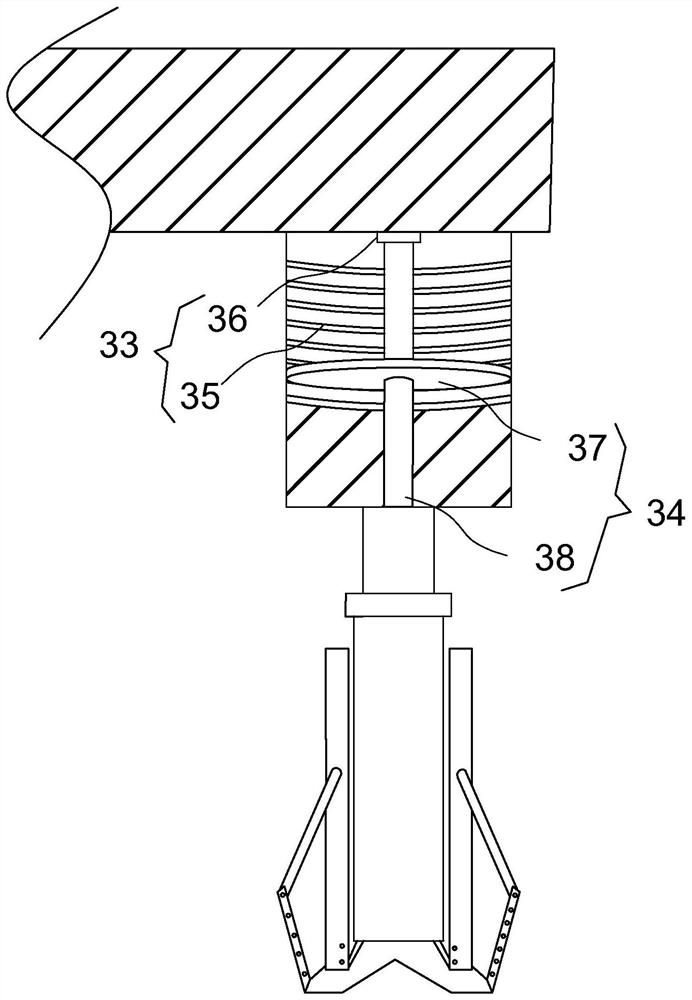

[0033] refer to Figure 1-Figure 6 , the present embodiment provides an aluminum alloy template, including a body, the body is formed by splicing two first templates 1 and second templates 2, and the connecting plate 3 is erected on the two first templates 1 .

[0034] The first formwork 1 and the second formwork 2 are spliced with each other using the installation device 4 , the upper surface of the first formwork is also recessed with channels 11 , and the connecting plate 3 is erected on the two channels 11 .

[0035] The first template 1 and the second template 2 are arranged perpendicular to each other, and the plurality of first templates are arranged in parallel and spaced apart.

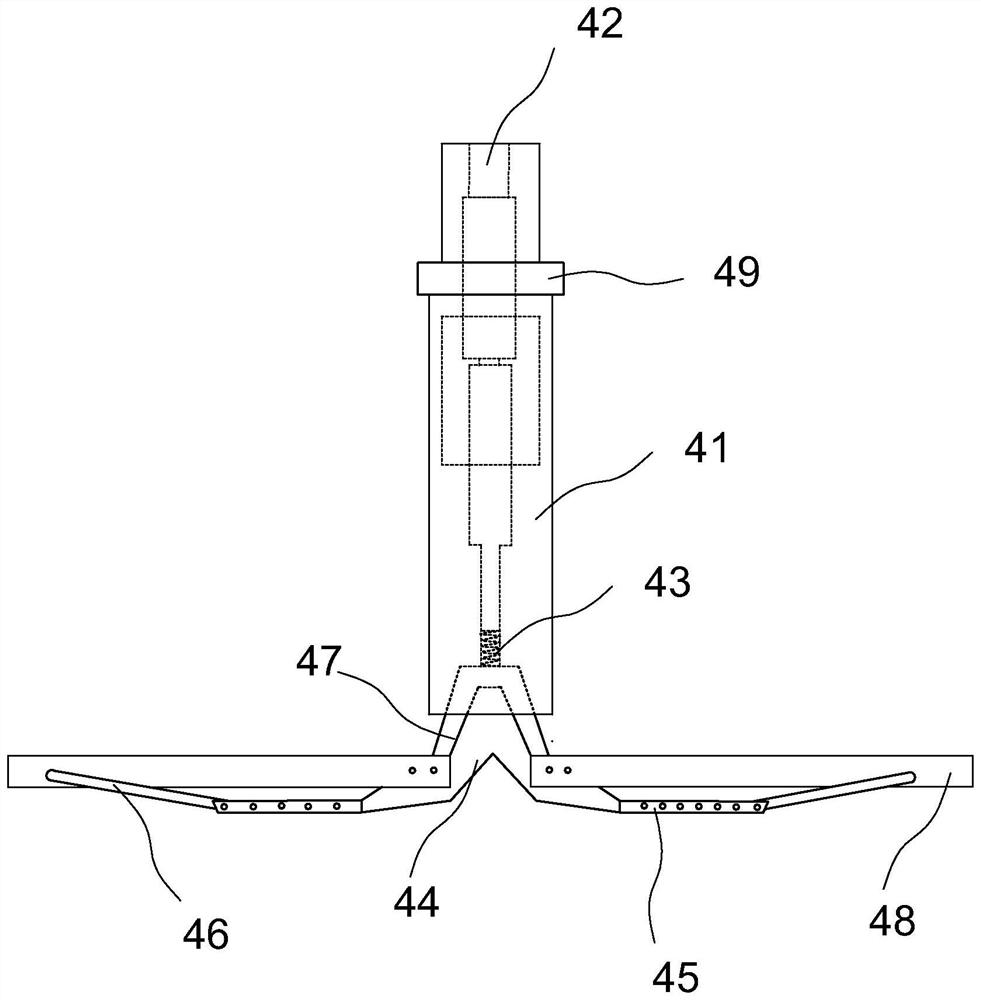

[0036] The installation device 4 includes a housing 41 , a connecting rod 42 , a spring 43 , a connecting frame 44 , a folding connecting rod 45 , a connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com