Method and structure for improving treatment rate of regenerative thermal oxidizer (RTO)

A combustion furnace, regenerative technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of difficult to clean, leaving dead corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

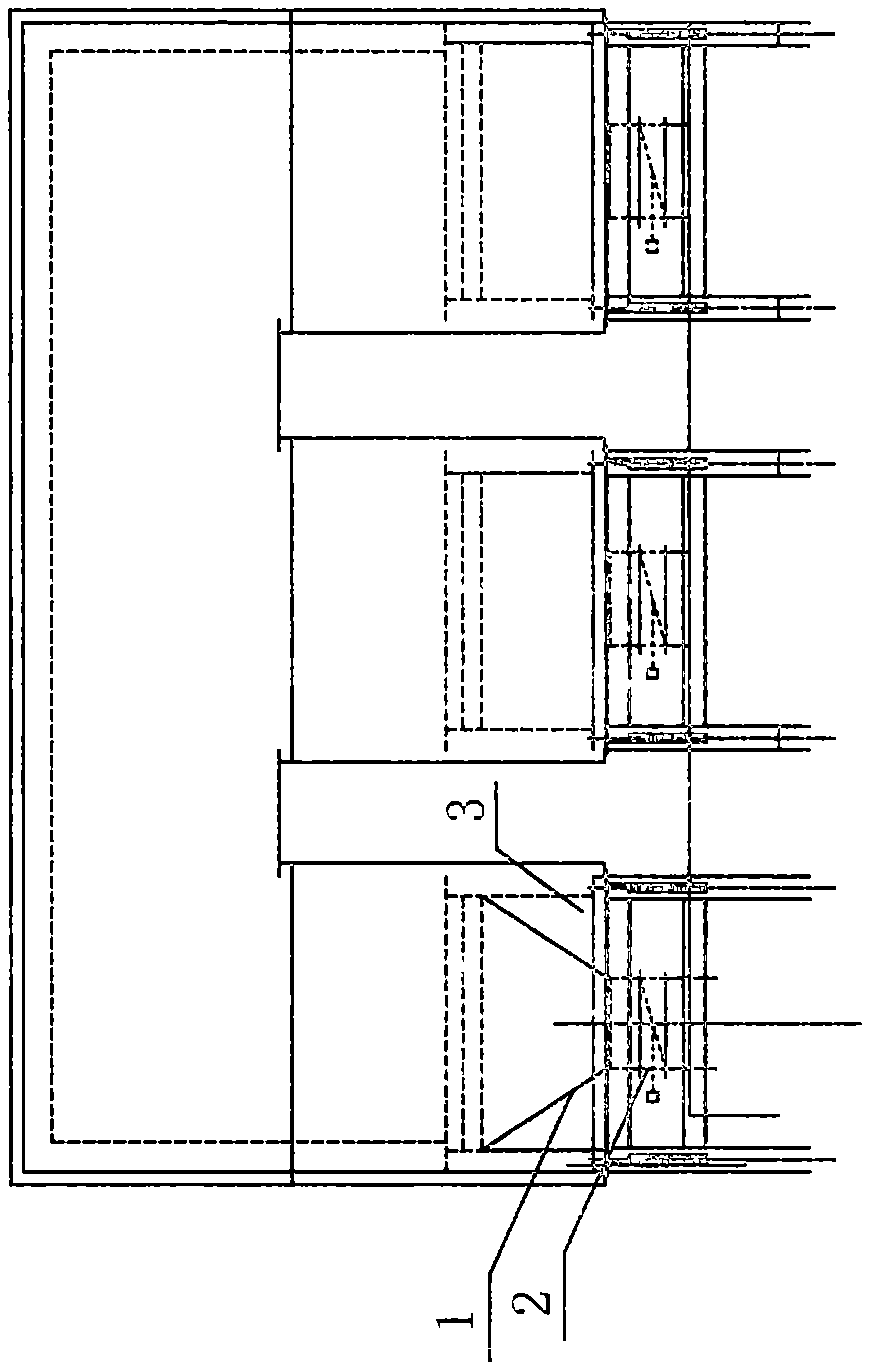

[0014] A circulation regenerative combustion furnace (RTO) structure to improve the treatment rate, characterized in that: the space between the valve of the circulation regenerative combustion furnace (RTO) and the regenerator is changed from a square space to a conical space, which is convenient for cleaning. No dead space left 3.

[0015] In the past, the exhaust gas and the treated flue gas entered and exited the RTO regenerator, and the square space structure was easy to manufacture, leaving dead corners 3, which were difficult to clean; it was changed to a tapered space, which was easy to clean and no dead corners were left 3 .

[0016] The new machine can be directly designed as a conical space; or for the exhaust gas and processed flue gas entering and exiting the square space structure near the RTO regenerator opening, use the plate 1 to seal the dead corner 3 to form a conical structure. The plate 1 can be sealed as a whole; or it can be stacked with multiple pieces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com