A current measuring device and measuring method based on a magnetic probe

A technology of a current measuring device and a magnetic probe, which is applied to the measuring device, measuring electrical variables, measuring only current, etc., can solve the problems of the measuring device's volume dependence, inability to perform current isolation measurement, and high price, so as to improve the resistance to external magnetic field interference. capability, improve adaptability and practicality, and achieve the effect of miniaturized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention.

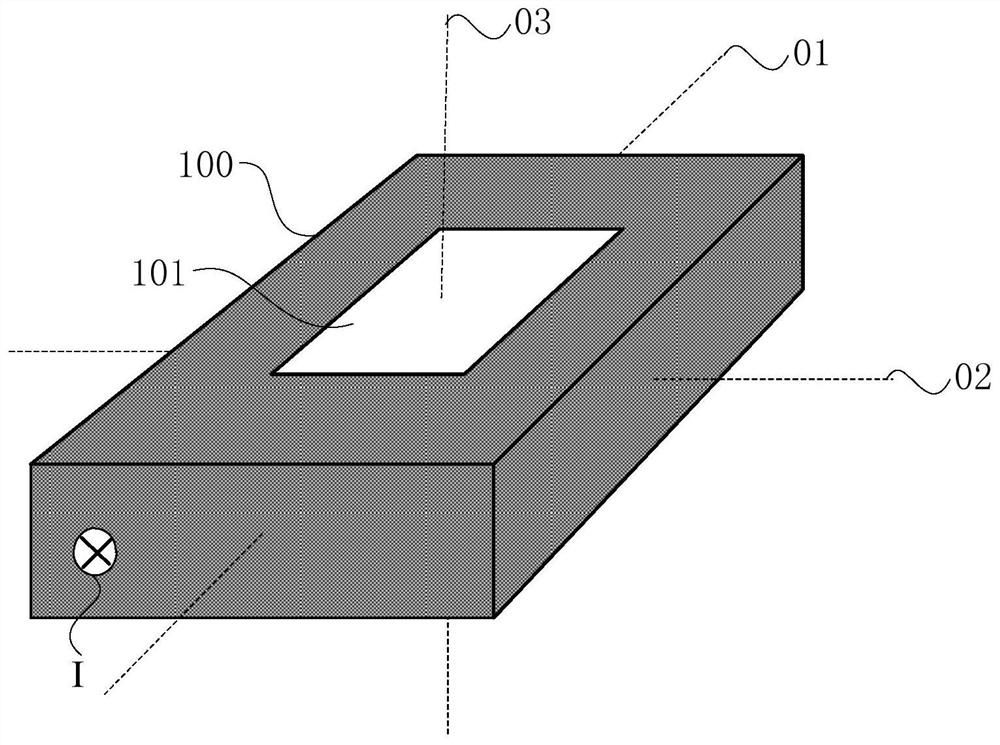

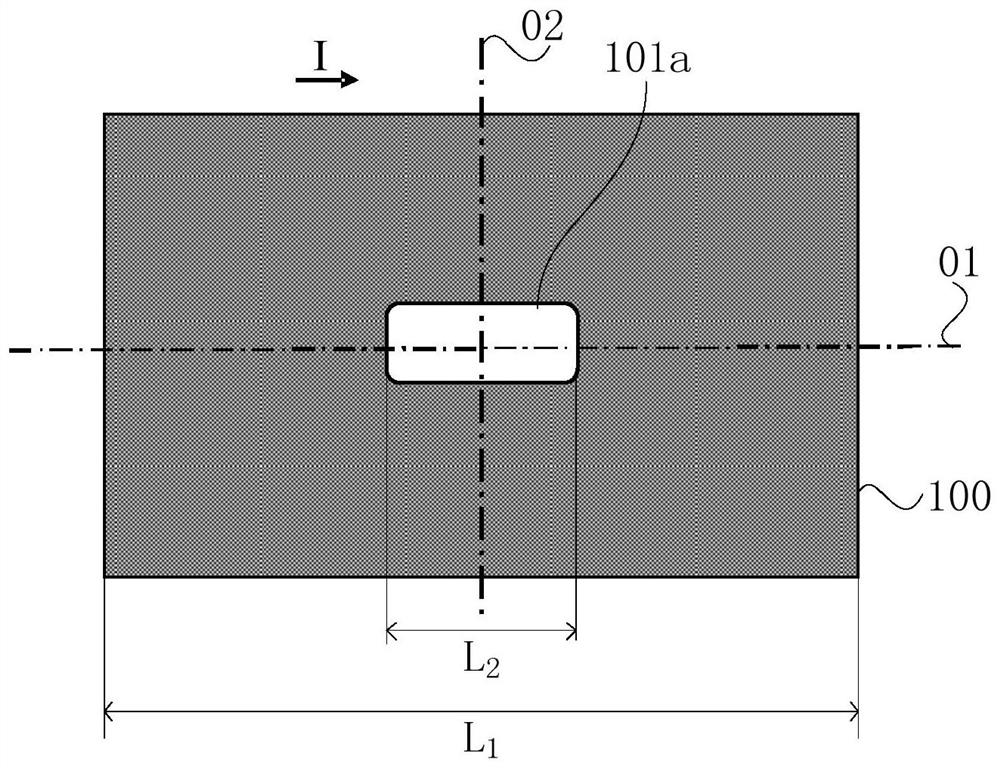

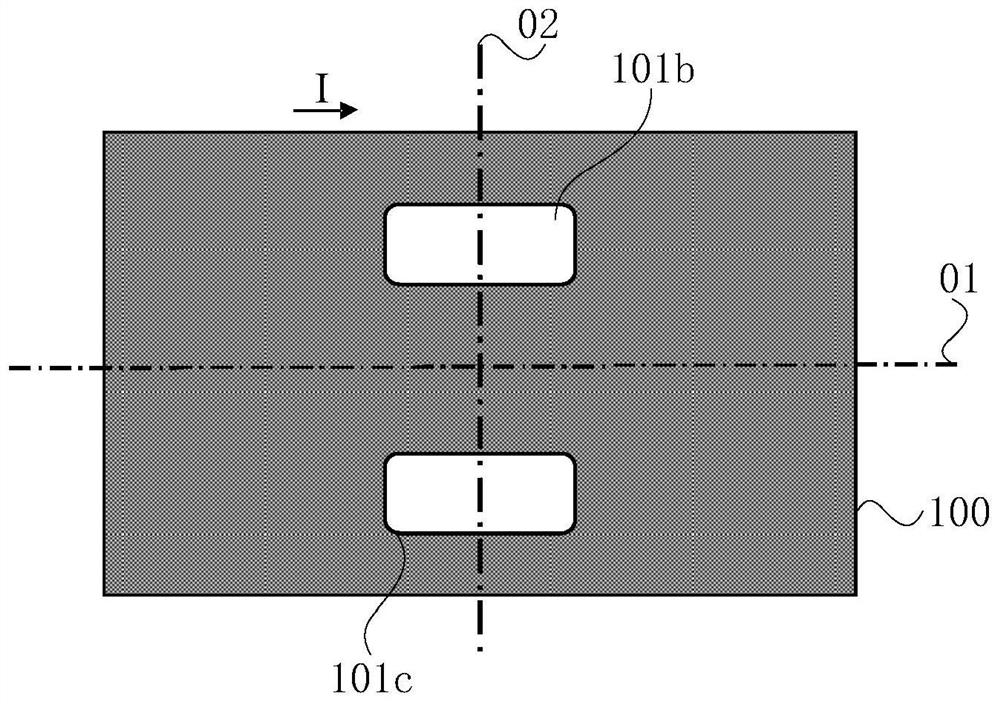

[0044] figure 1 is a three-dimensional structural schematic diagram of a current conductor under test provided by an embodiment of the present invention, to illustrate the axis layout of the current conductor under test; Figures 2a-2c It is a schematic diagram of the arrangement of the measured current conductor and its through holes provided by the embodiment of the present invention, and provides several arrangements of the through holes; image 3 is a schematic structural diagram of a current measurement device provided by an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com