Design method of lead-free flexible radiation protection material

A design method and radiation protection technology, applied in the field of nuclear technology application, can solve the problems of lead weak shielding area, easy to be inhaled into human body, easy to volatilize, etc., and achieve a heavy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

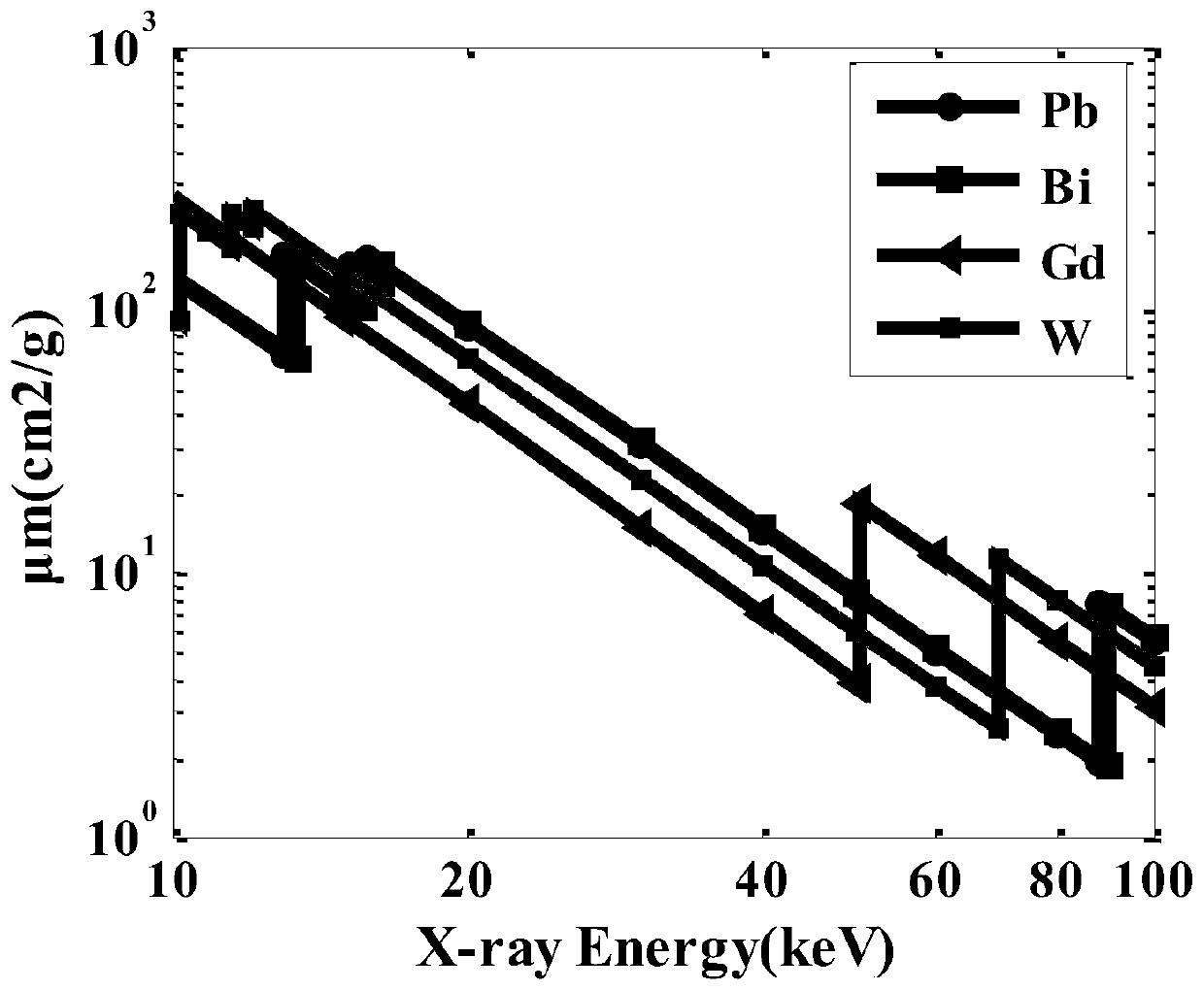

Embodiment 1

[0023] When the X-ray peak energy of the security inspection machine is around 90keV, the radiation protective clothing materials for the workers in production, commissioning, and use shall use flexible materials such as natural rubber as the base material, and the mass fraction of the base material shall be 50%, and bismuth oxide and Two materials of tungsten are used as functional filling materials. When the filling ratio is 1:1 and the material thickness is 1mm, the radiation shielding performance of the produced radiation protective clothing is improved by more than 20% compared with the traditional lead protective clothing; compared with only filling bismuth oxide, its The radiation shielding performance is improved by more than 20%.

Embodiment 2

[0025] X-ray peak energy in the 54 ~ 66keV X tube production, debugging, use and other staff radiation protective clothing materials, choose bismuth oxide and gadolinium oxide two materials as functional filling materials, the production of radiation protective clothing Radiation shielding performance is significantly better than traditional lead protective clothing. Natural rubber and other flexible materials are selected as the base material, and the mass fraction of the base material is 50%. When the filling ratio of bismuth oxide and gadolinium oxide is 1:1, and the material thickness is 1mm, the radiation protective clothing produced has less radiation than traditional lead protective clothing. The shielding performance is improved by more than 14%; compared with only filling bismuth oxide, the radiation shielding performance is improved by more than 14%.

Embodiment 3

[0027] The radiation protective clothing materials for workers in the production, debugging and use of industrial CT with X-ray peak energy greater than 100keV are selected to add bismuth oxide materials as functional filling materials, and the radiation shielding performance of the produced radiation protective clothing is significantly better than other lead-free materials. Radiation protective clothing made of functional filling materials. When the flexible material such as natural rubber is selected as the base material, the mass fraction of the base material is 50%, and the material thickness is 1mm, the radiation shielding performance is increased by more than 5% compared with filling bismuth oxide and gadolinium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com