Mixing apparatus for manufacture of polyamide wax

A technology of mixing and stirring polyamide wax, which is applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of serious dependence on manpower, low efficiency, and threats to the health of mixing people, and achieve high mixing efficiency, The effect of improving efficiency and avoiding health threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

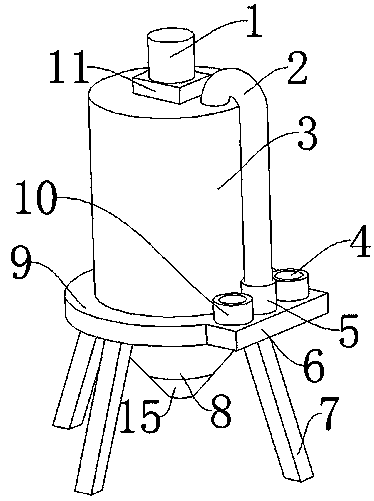

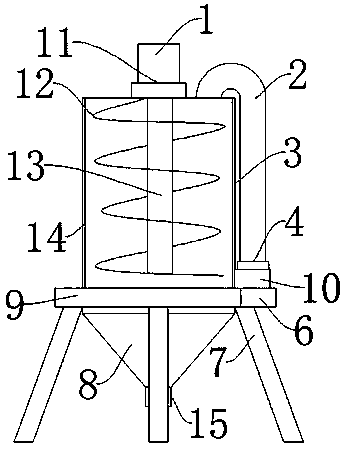

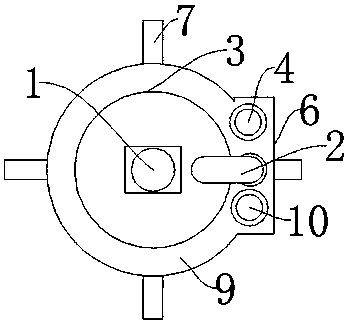

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1-Figure 3 As shown, a mixing and stirring device for polyamide wax production includes a stirring tank 3, a first feed hopper 4, a feed pump 5, a spiral stirring blade 12, a heating resistance wire layer 14, and a speed reducer is arranged on the top of the stirring tank 3 11. The stirring tank 3 is used to provide a reaction environment for the material, the reducer 11 is used to reduce the speed of the stirring motor 1, the top of the reducer 11 is provided with a stirring motor 1, and the stirring motor 1 is used to provide power for the rotation of the stirring shaft 13. A feed pipe 2 is provided on one side of the motor 1, and the feed pipe 2 is used for material circulation. A feed pump 5 is provided at the bottom of the feed pipe 2. The feed pump 5 is used to provide power for the transportation of materials. The bottom of the feed pump 5 A f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com