High-temperature-resistant self-watering flowerpot

A technology for preventing high temperature and flower pots, applied in automatic watering devices, container cultivation, gardening, etc., can solve the problems of inability to live experience, reduced oxygen content, and plants are prone to water shortage, and achieve the effect of increasing life experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

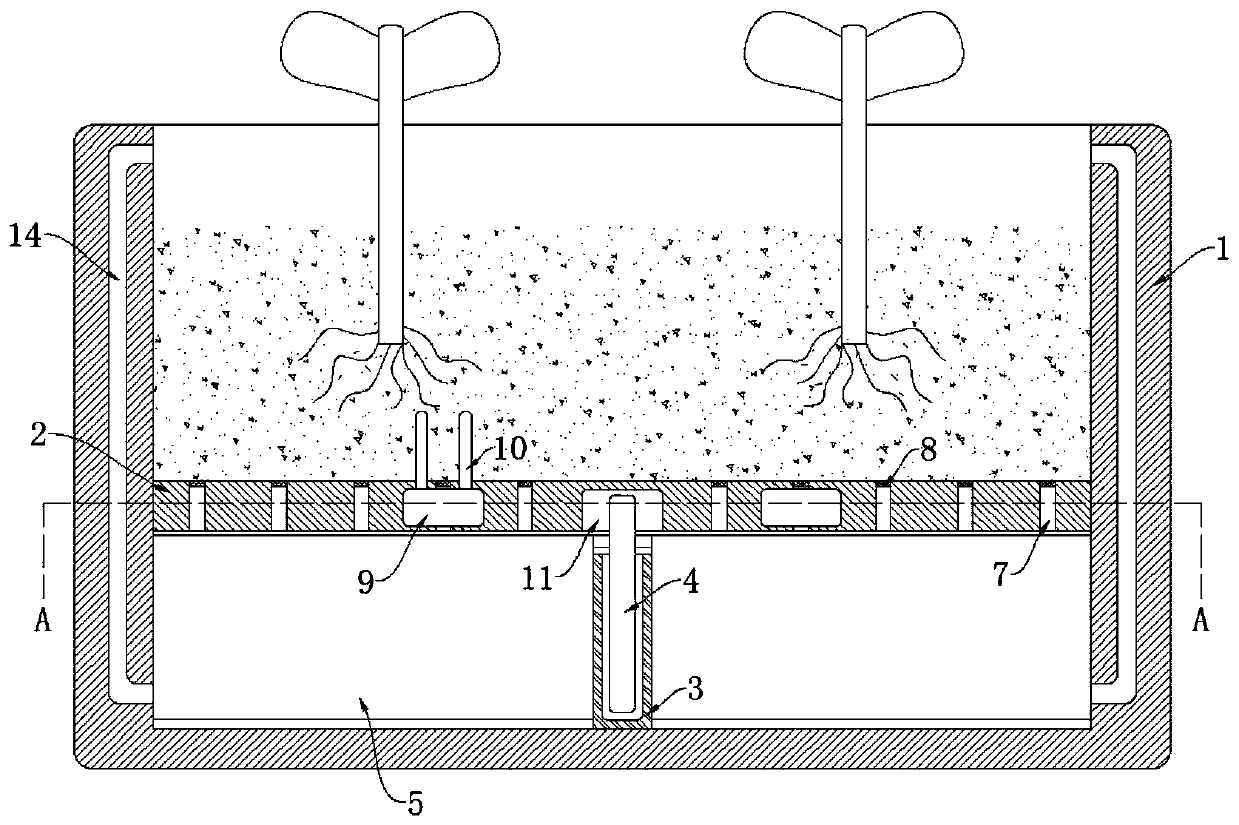

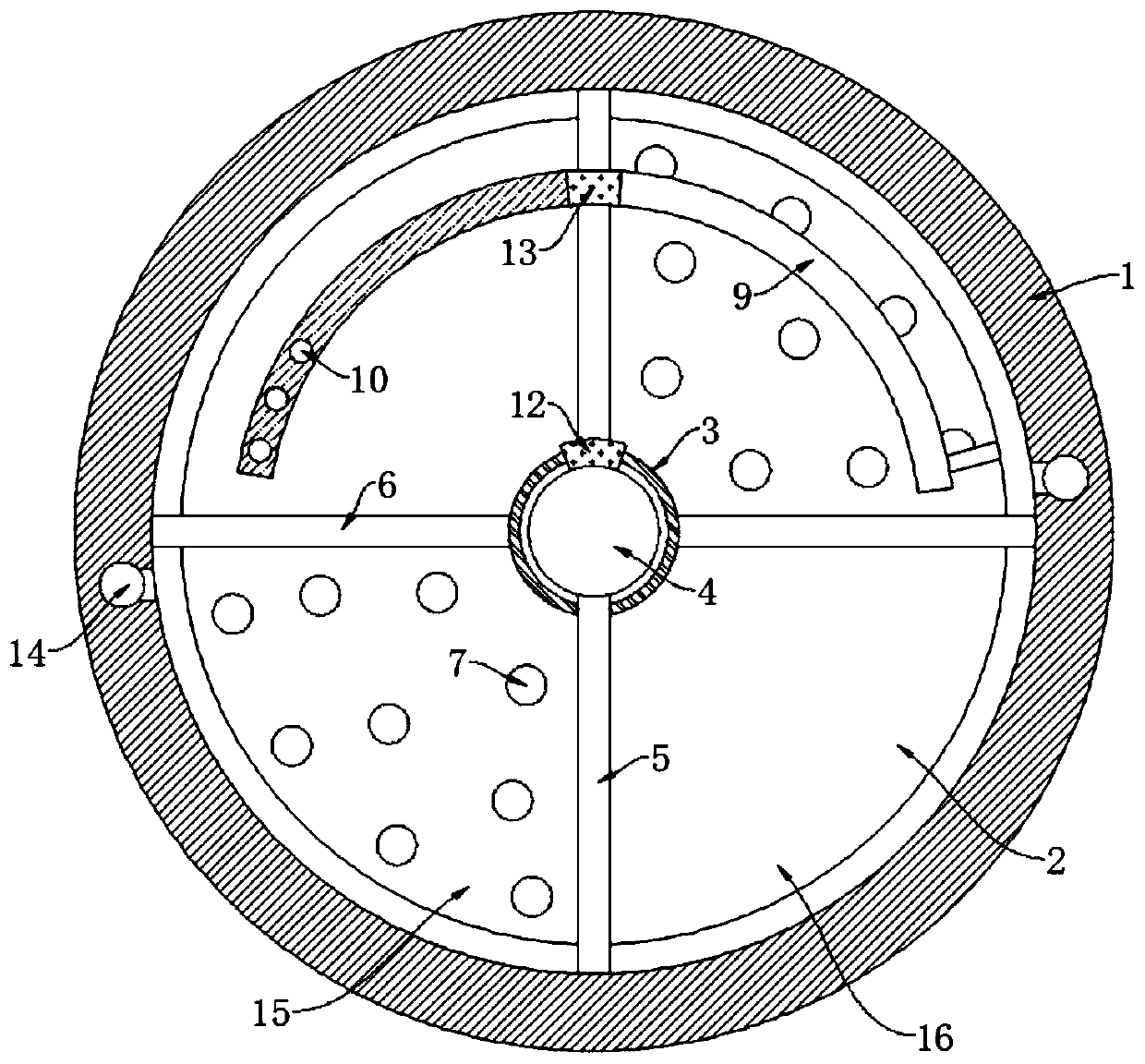

[0023] refer to Figure 1-2 , a self-watering anti-high temperature flower pot, comprising a pot body 1, the inner wall of the pot body 1 is fixedly connected with a baffle plate 2, the inner bottom of the pot body 1 is fixedly connected with a cylinder 3, and the inner wall of the cylinder 3 is rotatably connected with a vertical rod 4. The side wall of the vertical rod 4 is fixedly connected with the first partition 5 through the connecting rod, and the first partition 5 is sealed and slidingly connected with the side wall of the cylinder 3 and the inner wall of the basin body 1, and the opposite side wall of the cylinder 3 is fixedly connected with the second partition. Two partitions 6, the first partition 5, the second partition 6 and the inner wall of the basin body 1 form the first chamber 15 and the second chamber 16, and the first chamber 15 is filled with nutrient solution, further, the basin body 1. The side wall is provided with a liquid inlet connected to the firs...

Embodiment 2

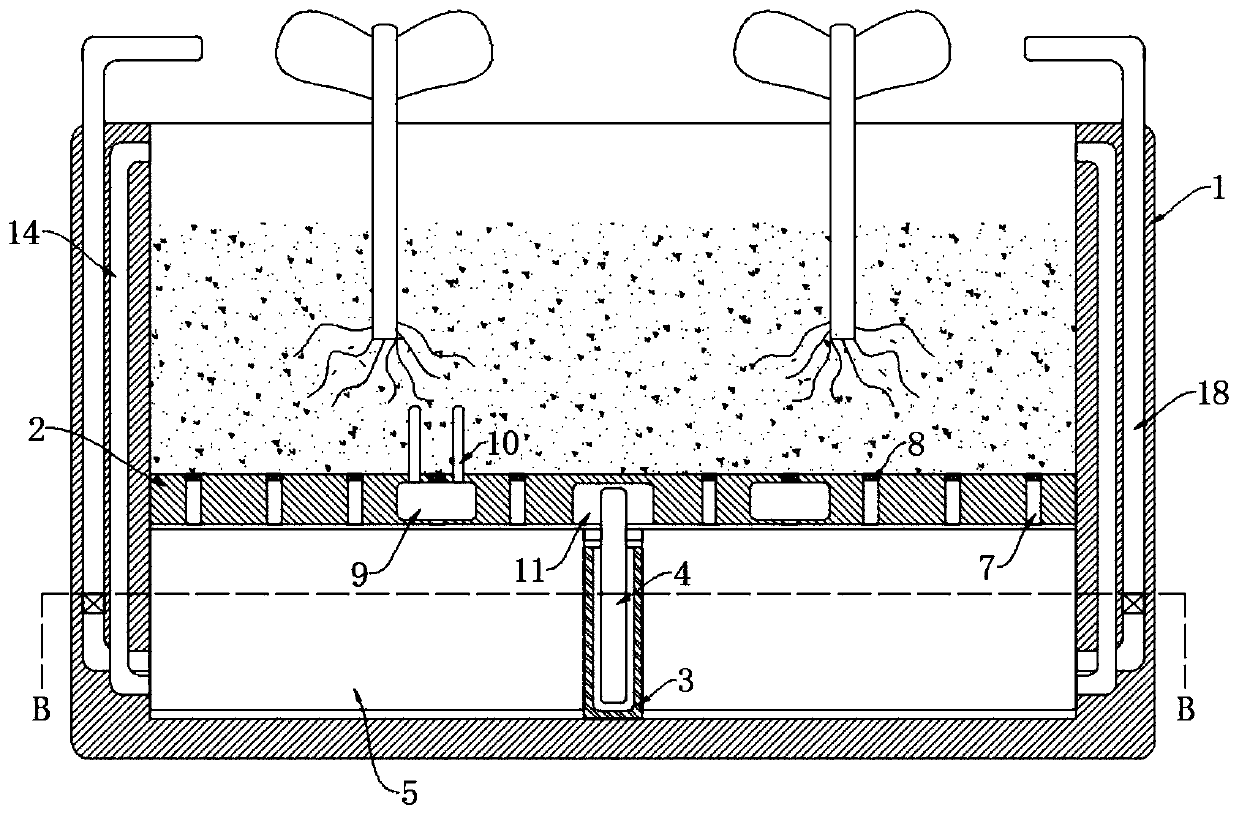

[0027] refer to Figure 3-4 Different from Embodiment 1, the inner wall of the second chamber 16 is fixedly connected with a flexible air bag 17, and the opposite side wall of the basin body 1 is connected with a one-way air jet pipe 18. The dust on the air is blown off, and the lower end of the one-way jet pipe 18 communicates with the side wall of the telescopic air bag 17, and the side wall of the telescopic air bag 17 is connected with a one-way suction pipe 19. It should be noted that the one-way jet pipe 18 and the one-way suction pipe The trachea 19 can realize its function by installing a one-way valve on its inner wall.

[0028] In this embodiment, when the evaporating liquid is heated and vaporized and expanded, the vertical rod 4 drives the first partition plate 5 to rotate, so that the volume of the first chamber 15 decreases, and the volume of the second chamber 16 increases, so that it is compatible with the second chamber. The telescopic airbag 17 fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com