Power supply control system for washing electric appliance

A technology of power control and electrical appliances, which is applied in the direction of washing control program, tableware washing machine/rinsing machine, tableware washing machine/rinsing and washing machine parts, etc., which can solve problems such as irregular grounding wires, electric shock risks, and human injury. Achieve the effects of avoiding fire accidents, improving electricity safety, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

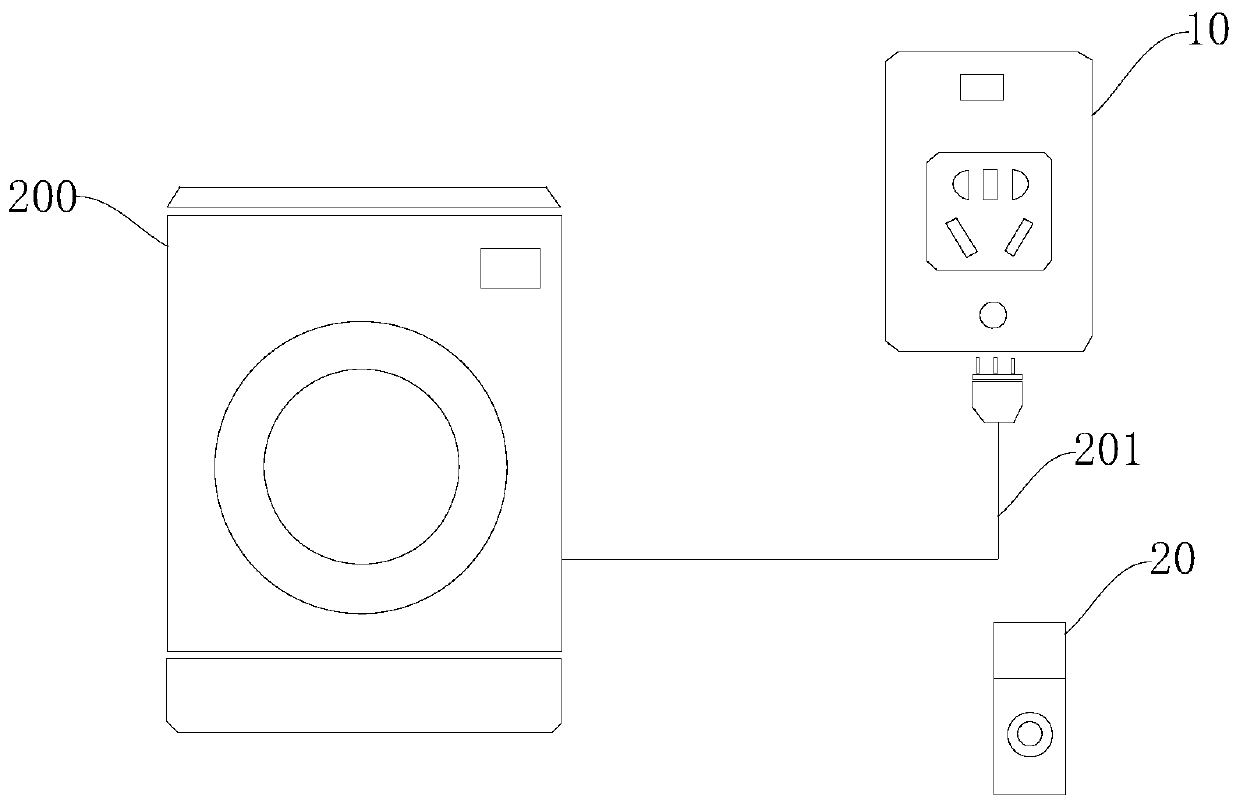

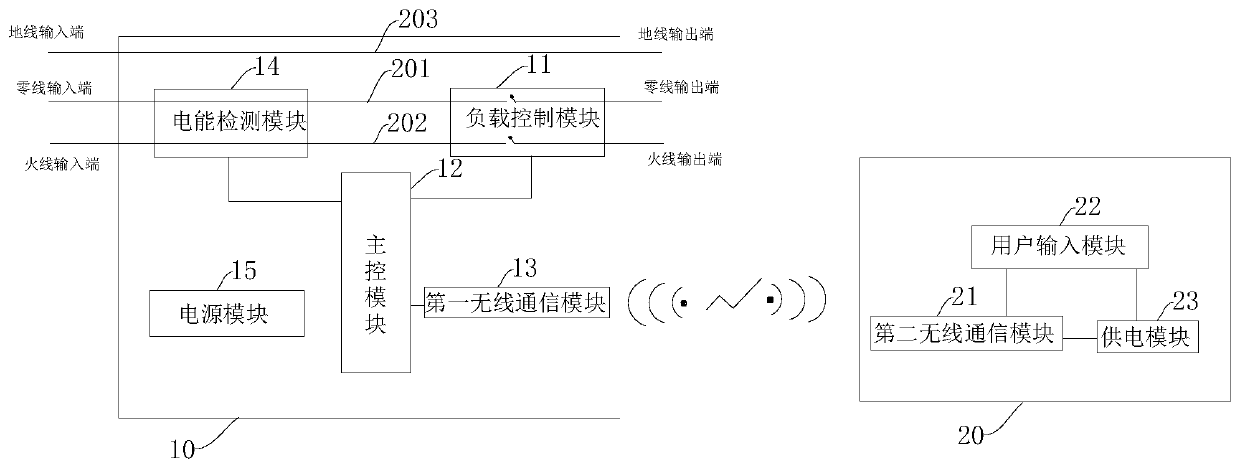

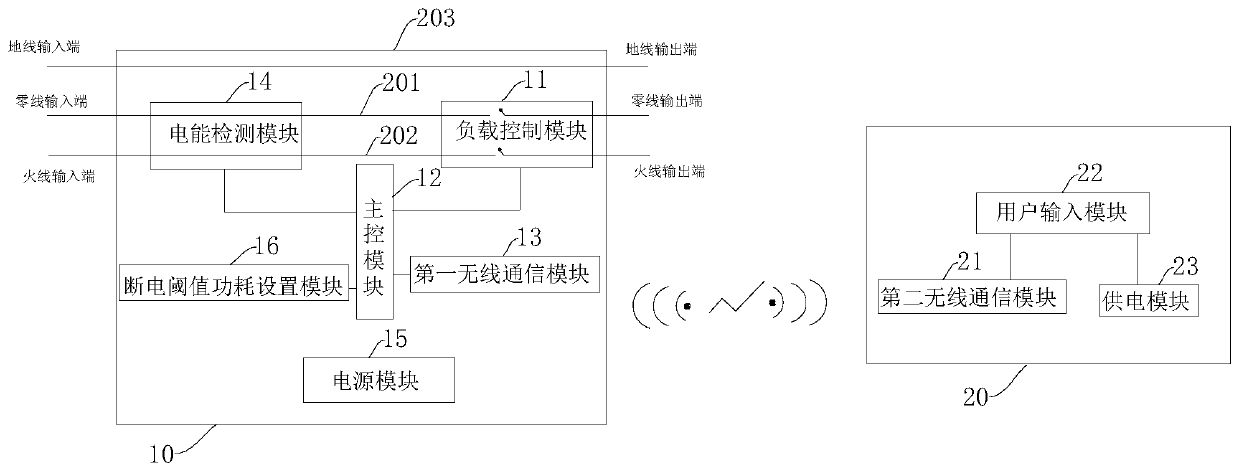

[0036] Refer below Figure 1-Figure 8 , to describe the power control system 100 for washing appliances according to the embodiment of the present invention. The power control system 100 includes a socket unit 10 and a remote controller 20 . The power control system 100 can be applied to dishwashers, washing machines, washing and drying machines, and the like.

[0037] Wherein, the socket unit 10 can be directly installed on the wall, and the load of the washing appliance 200 is directly inserted on the socket unit 10, or the socket un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com