Back plate cleaning assembly capable of avoiding raised dust

A technology for cleaning components and backplanes, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, which can solve problems such as the inability to effectively ensure the flow of foreign objects in the space, and achieve the effect of preventing cross-contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

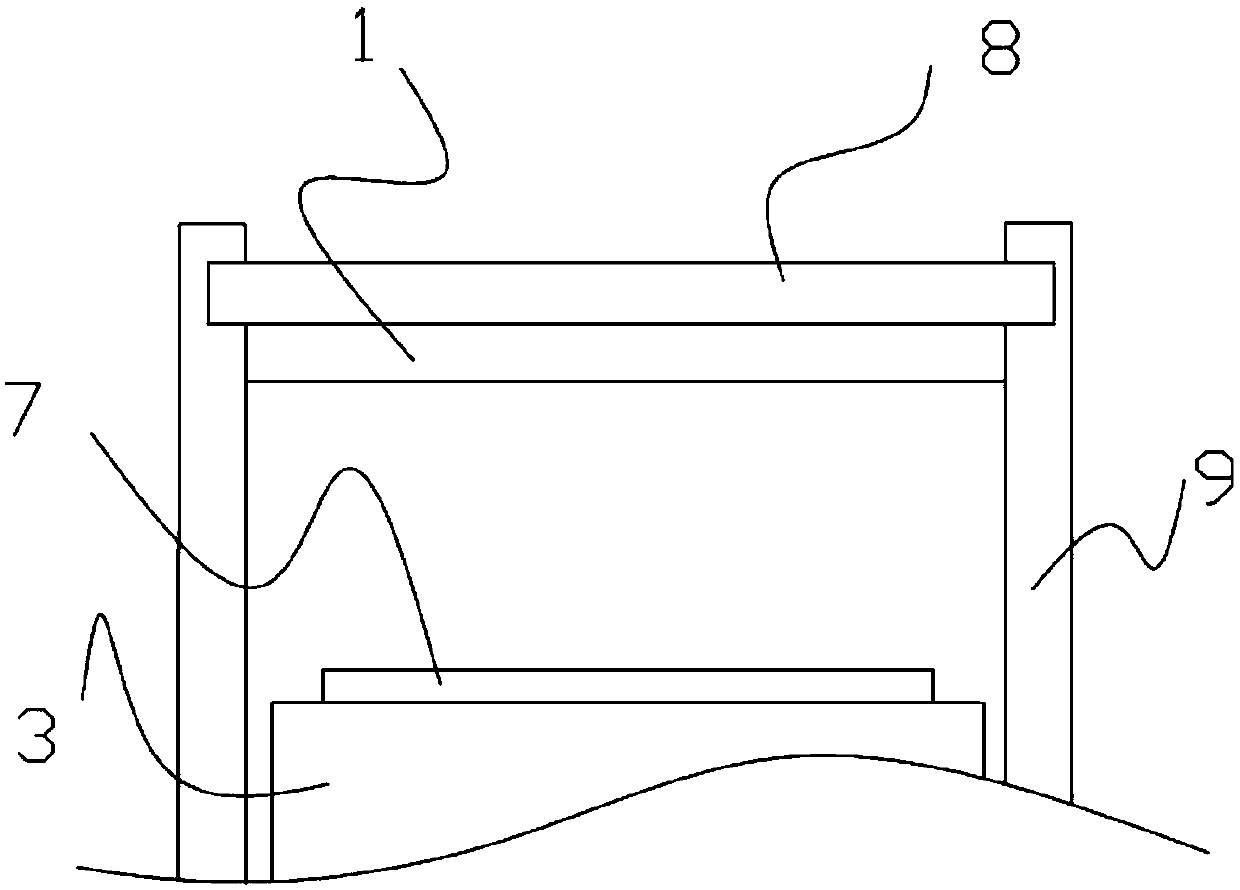

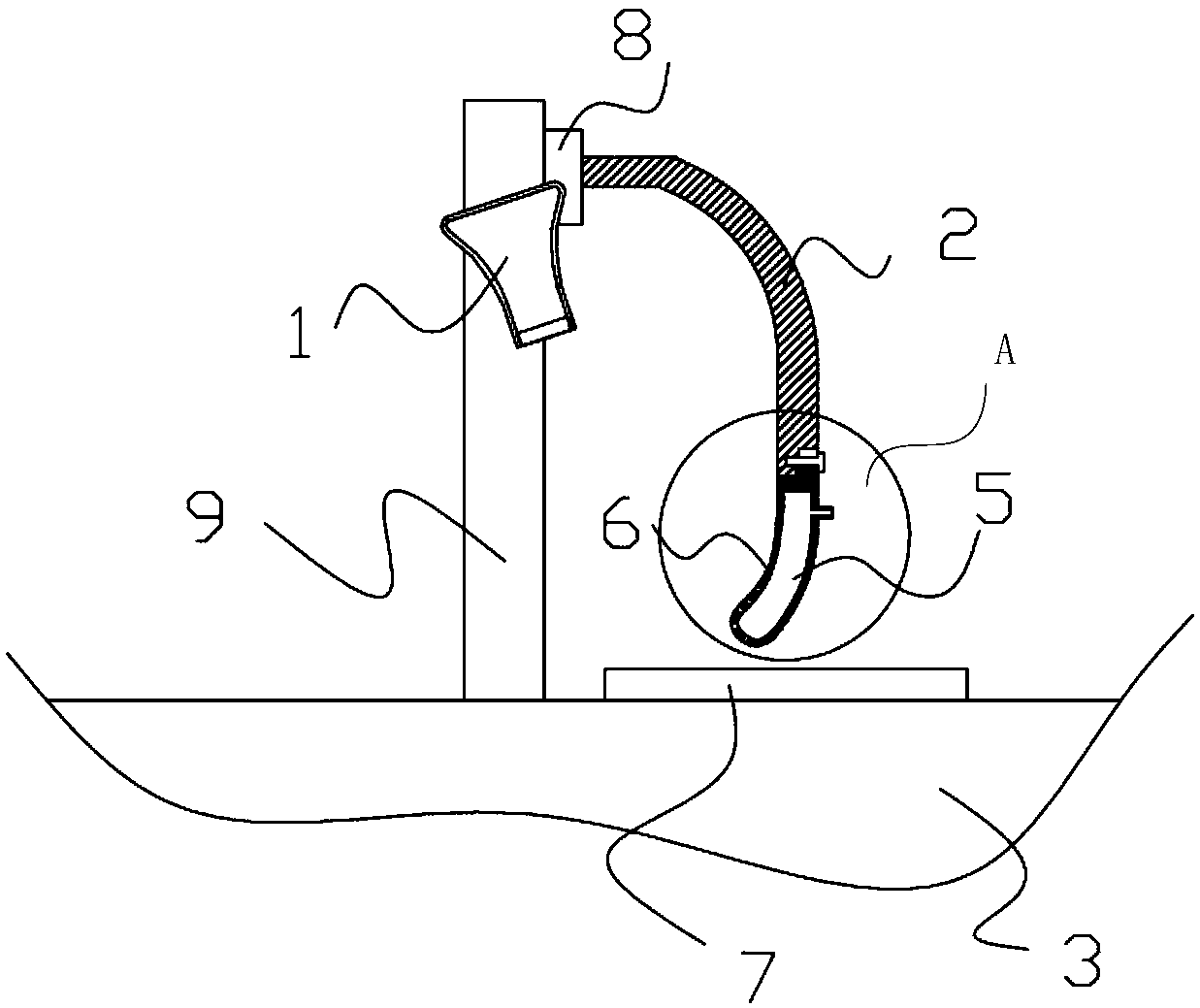

[0025] In order to solve the technical problem of cross-contamination caused by foreign matter flowing in the work room in the prior art, this embodiment provides a backplane 7 cleaning assembly that avoids dust, which is characterized in that it includes an air knife 1 and a dust collection board 2, The air knife 1 is fixed above the workbench 3, and the dust collection plate 2 is arranged opposite to the air outlet 4 of the air knife 1;

[0026] Both sides of the workbench 3 are provided with support ribs 9, the air knife 1 is fixed between the two support ribs 9 by bolts, and the dust collection plate 2 is fixed to the support ribs 9 by a horizontal plate 8 connect;

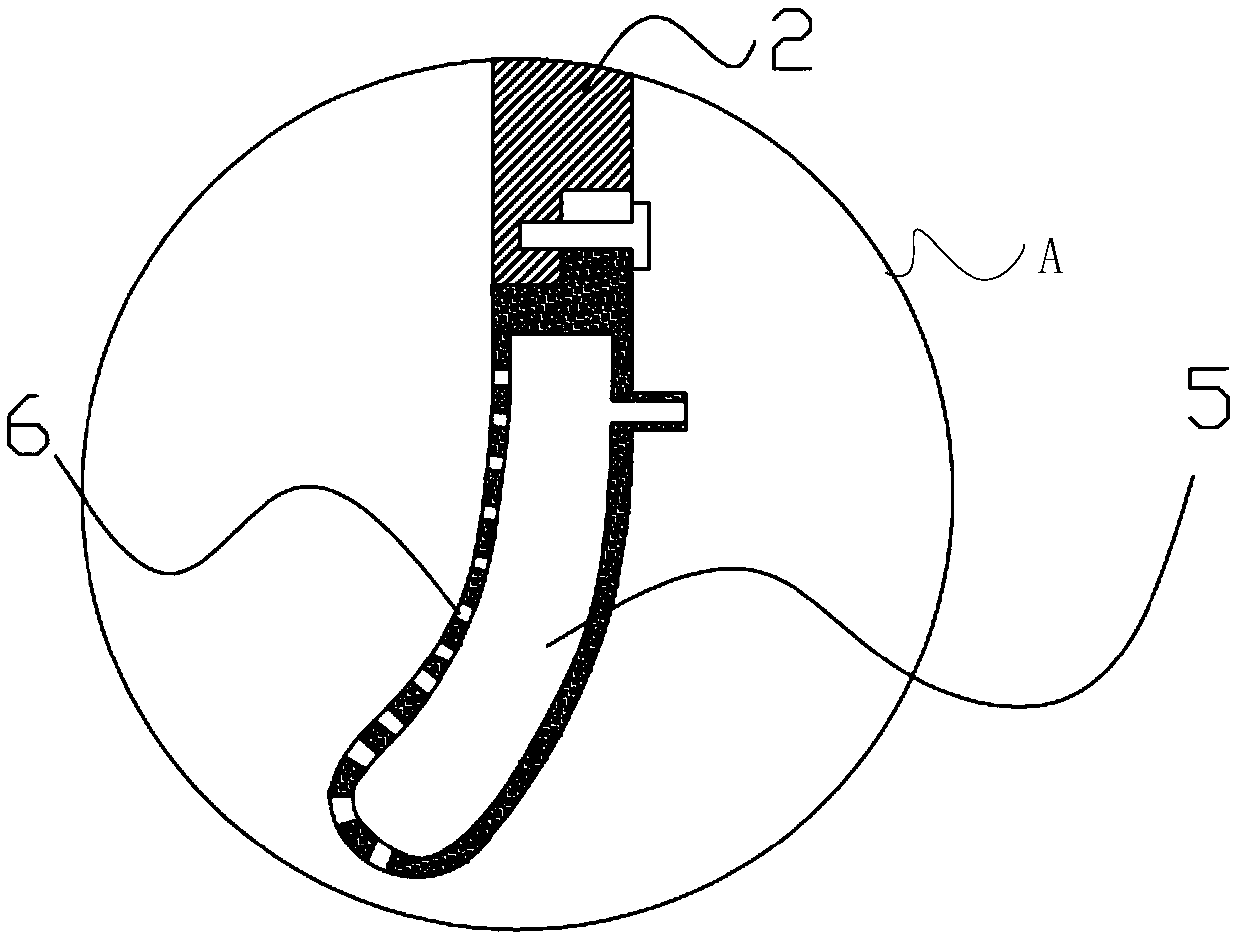

[0027] The dust collection plate 2 includes an arc-shaped baffle sunken toward the air knife 1, and the bottom end of the arc-shaped baffle is provided with a negative pressure cavity 5, and the negative pressure cavity 5 is close to the bottom of the air knife 1. One side is provided with suction hole 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com