Soaking and disinfection device for rigid endoscope

A sterilization device and a rigid technology, applied in the field of medical devices, can solve problems such as contamination of rigid endoscopes, and achieve the effects of improving the effect, avoiding cross-contamination, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

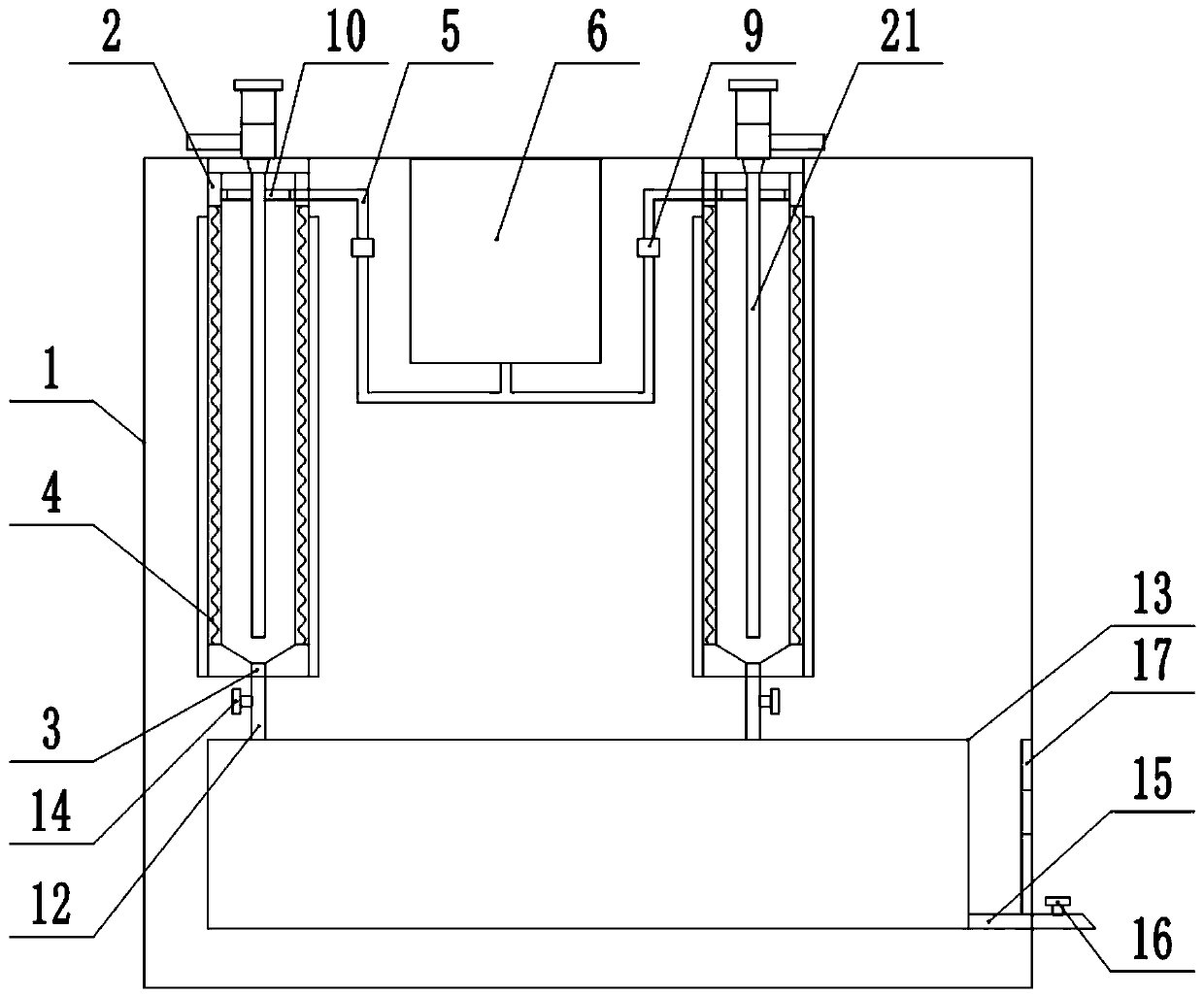

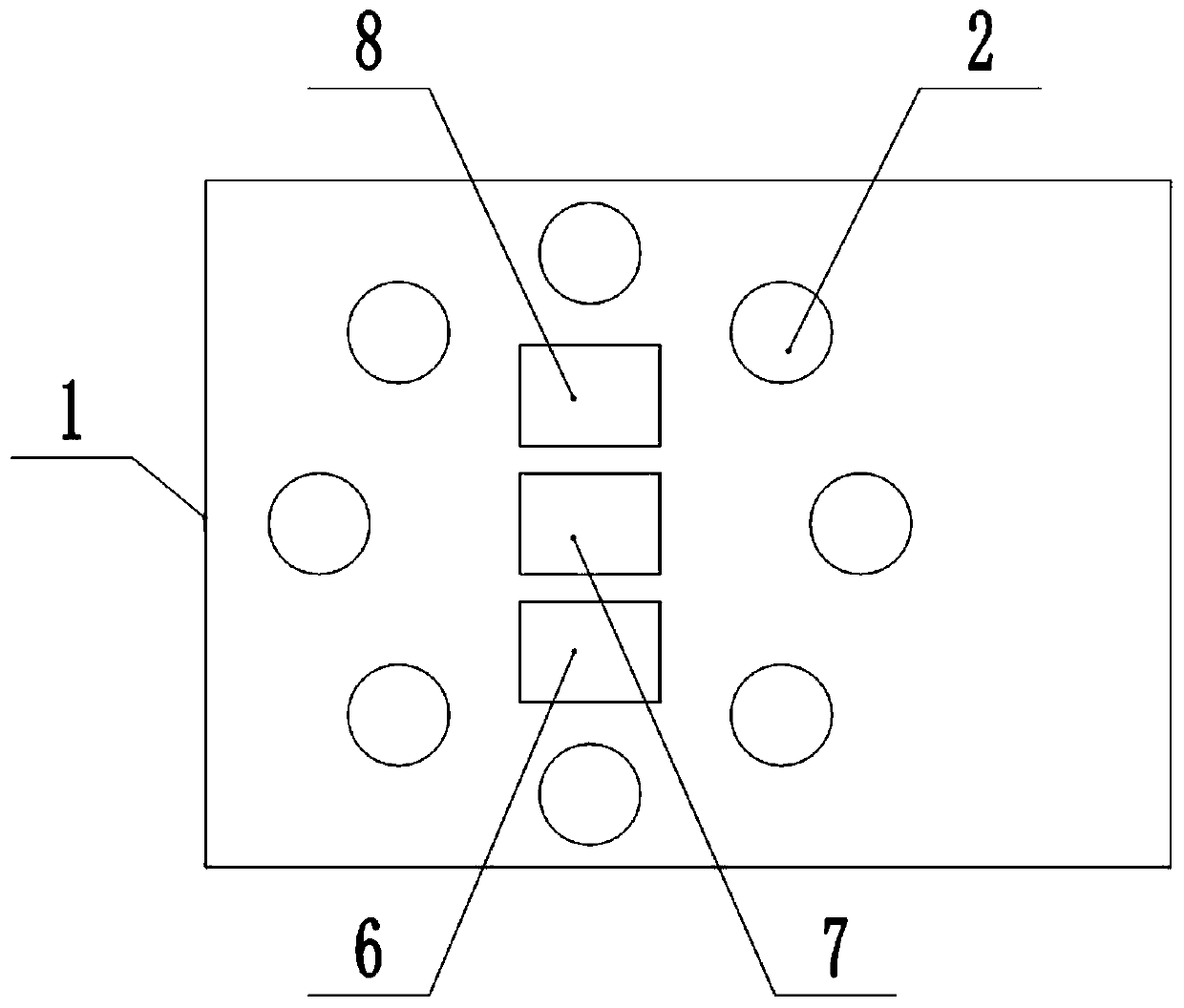

[0028] Embodiment one is basically as attached Figures 1 to 3 Shown:

[0029] A device for immersing and disinfecting rigid endoscopes, comprising a housing 1, in which at least two hollow cleaning barrels 2 are clamped and fixed. In this embodiment, the number of cleaning barrels 2 is eight, and the Circular array distribution. The top of the cleaning bucket 2 is provided with a socket for inserting the rigid endoscope 21, and two shrapnels are bonded in the socket. After the mirror 21 is inserted, the shrapnel plays a role of limiting and fixing the rigid endoscope 21 . The bottom of the cleaning bucket 2 is provided with a liquid discharge port 3, and the bottom of the cleaning bucket 2 is inclined to the liquid discharge port 3, so that water and solution can flow out of the liquid discharge port 3.

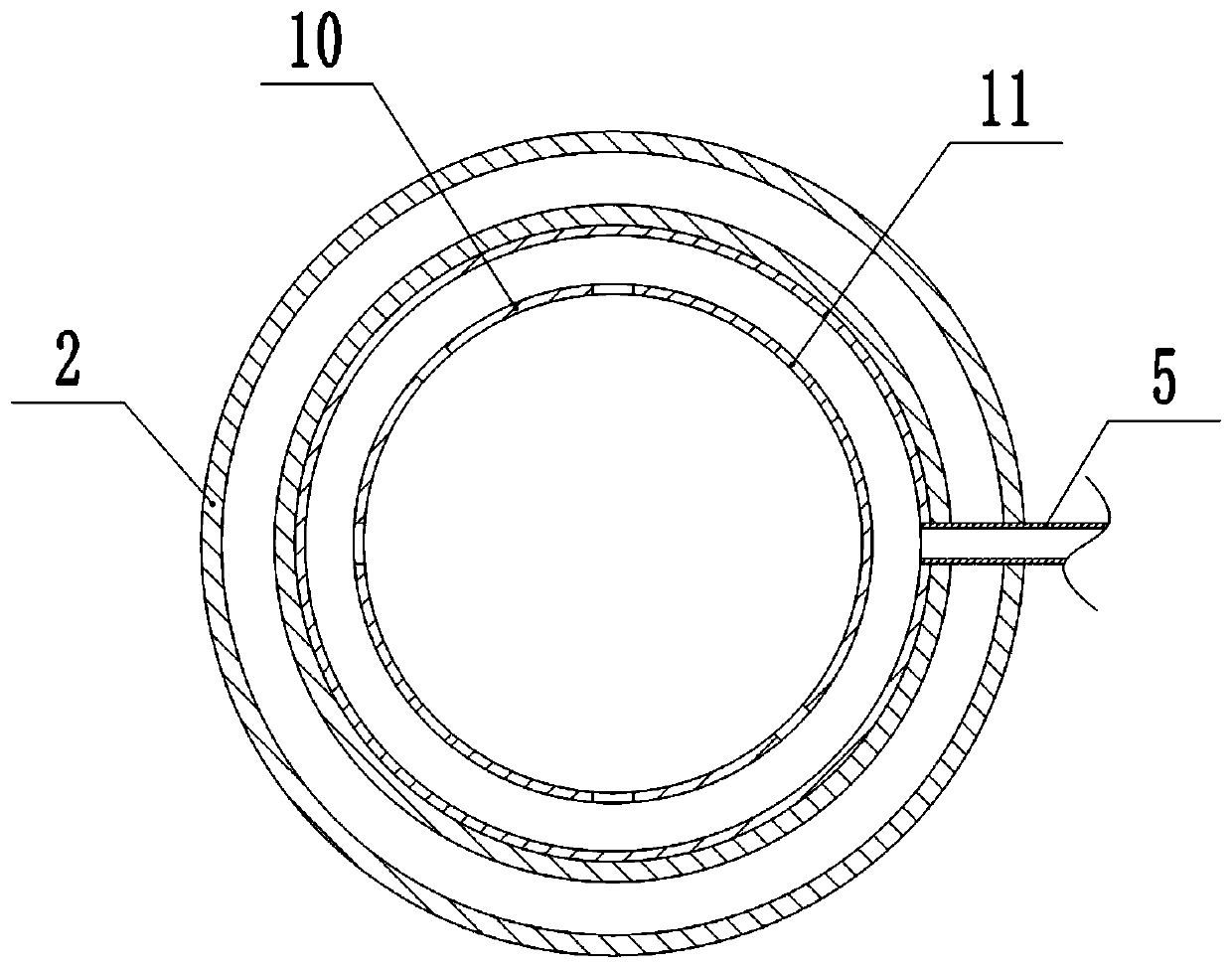

[0030] The cleaning barrel 2 is provided with a heating element. In this embodiment, the heating element is a heating wire 4. There is a cavity in the inner wall of the c...

Embodiment 2

[0034] Embodiment two is basically as attached Figure 4 And attached Figure 5 Shown:

[0035] The difference between this embodiment and Embodiment 1 is that a controller 18 is fixed by bolts in the housing 1. In this embodiment, the controller 18 is a PLC controller 18 (disclosed in the prior art), and the drain valve 14 is an electromagnetic valve. The valve, the drain valve 14 , the first pump body 9 , the second pump body and the third pump body are all electrically connected to the controller 18 . A display panel 19 electrically connected to the controller 18 is clamped on the casing 1 , and a control key 20 is arranged on the display panel 19 .

[0036] During specific implementation, the opening and closing of the drain valve 14, the first pump body 9, the second pump body, and the third pump body are controlled by the controller 18, without manual operation of each process, so as to achieve automatic control and improve the efficiency of cleaning and disinfection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com