Hot metal bottle heat preservation protection device on hot metal vehicle

A protective device and molten iron tank technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems that threaten the safety of molten iron vehicles, personnel and facilities along the way, affect steel production, and heat loss, and achieve significant economic benefits. Benefits and social benefits, improving smelting production efficiency, and ensuring safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

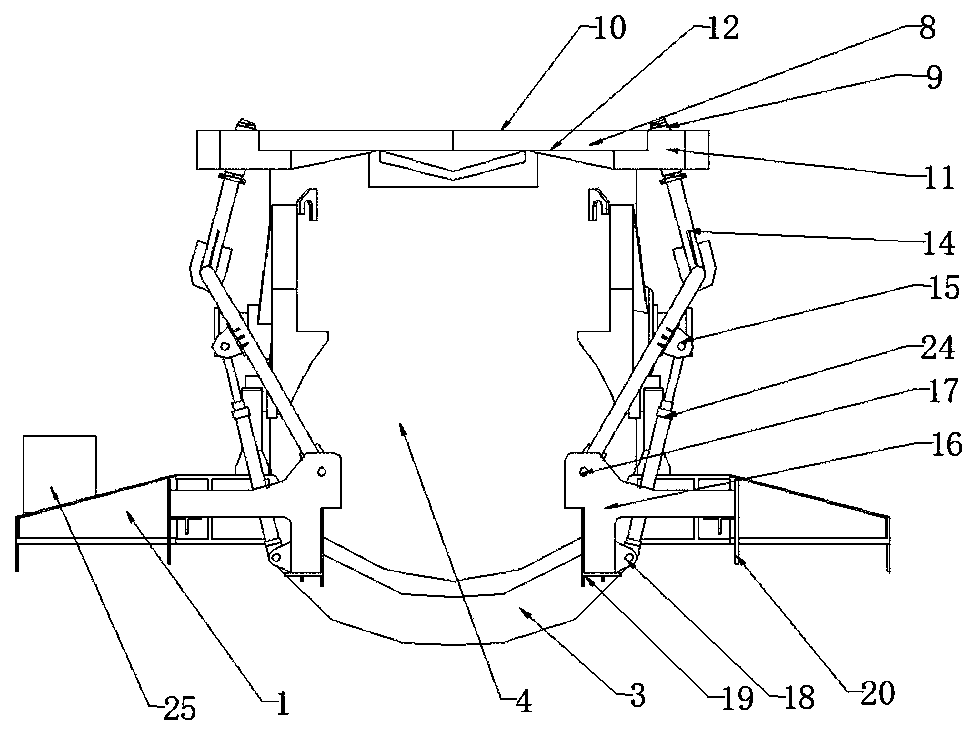

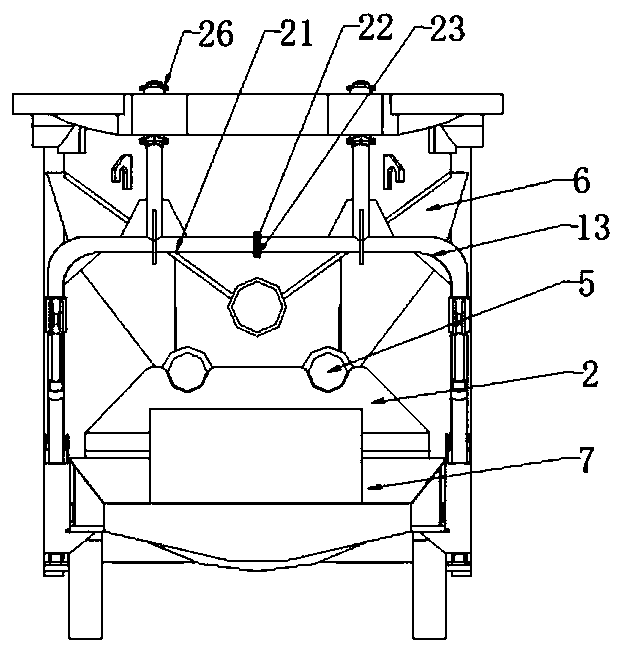

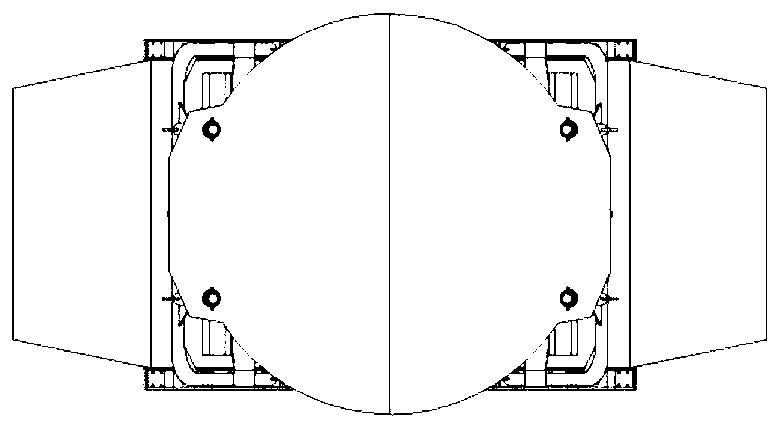

[0034] Refer to attached Figure 1-20 , a hot metal tank insulation protection device on a hot metal car, comprising a hot metal car 1, a hot metal tank saddle 2, a hot metal tank 4, a protective cover 8, a support arm 14, a support arm connection seat 15, a support seat 16, and a support arm hinge seat 17. Hydraulic cylinder articulated seat 18, support arm stabilizer bar 21, stabilizer bar connecting seat 22 and hydraulic cylinder 24, the molten iron tank 4 is fixed on the molten iron vehicle 1 through the molten iron tank saddle 2, and the upper end of the molten iron tank 4 is an open structure, The protective cover 8 is composed of two semicircular covers, which match the opening of the upper end of the ladle after the two semicircular covers are docked, and the semicircular cover includes a semicircular top plate 10 and side plates 11. Support arms 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com