A kind of smelting process of molten alloy steel for preparing iron-based amorphous broadband

An iron-based amorphous and alloy steel technology, which is applied in the improvement of process efficiency, furnace type, furnace and other directions, can solve the problems of increasing molten steel pollution, large comprehensive energy consumption, and increasing burning loss, etc., to improve smelting production efficiency, Reduce comprehensive energy consumption and reduce the effect of gag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

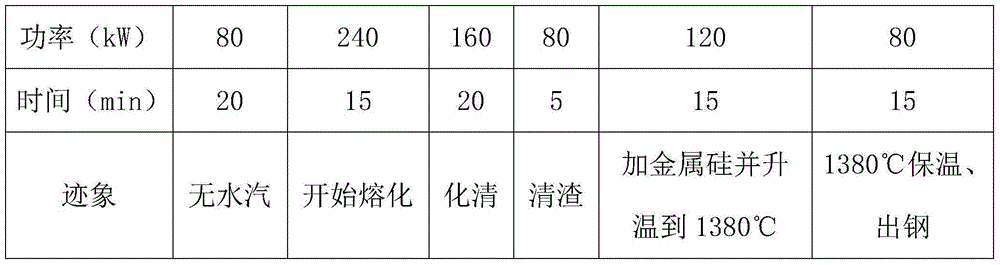

[0025] Example 1 of the smelting process of molten alloy steel for the preparation of iron-based amorphous broadband according to the present invention, taking the smelting of an iron-based amorphous master alloy with a standard mass fraction of Fe92.1Si5.4B2.5 as an example. Its process steps include in turn:

[0026] Step 1. Ingredients: Weigh industrial pure iron, low-aluminum-boron iron and metal silicon according to the standard composition requirements of the iron-based amorphous master alloy, wherein the boron content of the low-aluminum-boron iron is 17 to 19 wt%. In addition to adding industrial pure iron, industrial silicon and ferroboron, ferro-niobium and electrolytic copper are generally added, but in the present invention, only industrial pure iron, ferroboron and metal silicon are added, and ferroboron is selected from low-aluminum ferroboron, Elimination of high-temperature decarburization, reducing agent and additive mixing slagging, etc., contributes to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com