Magnesium crystallizer

A technology of crystallizer and conical cylinder, applied in the field of magnesium crystallizer for Pidgeon process magnesium smelting, can solve the problems of reducing the production efficiency of magnesium reduction cycle, increasing the labor intensity of workers, complex structure design, etc., and achieves simple structure, high output Magnesium pressed magnesium is convenient and has the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

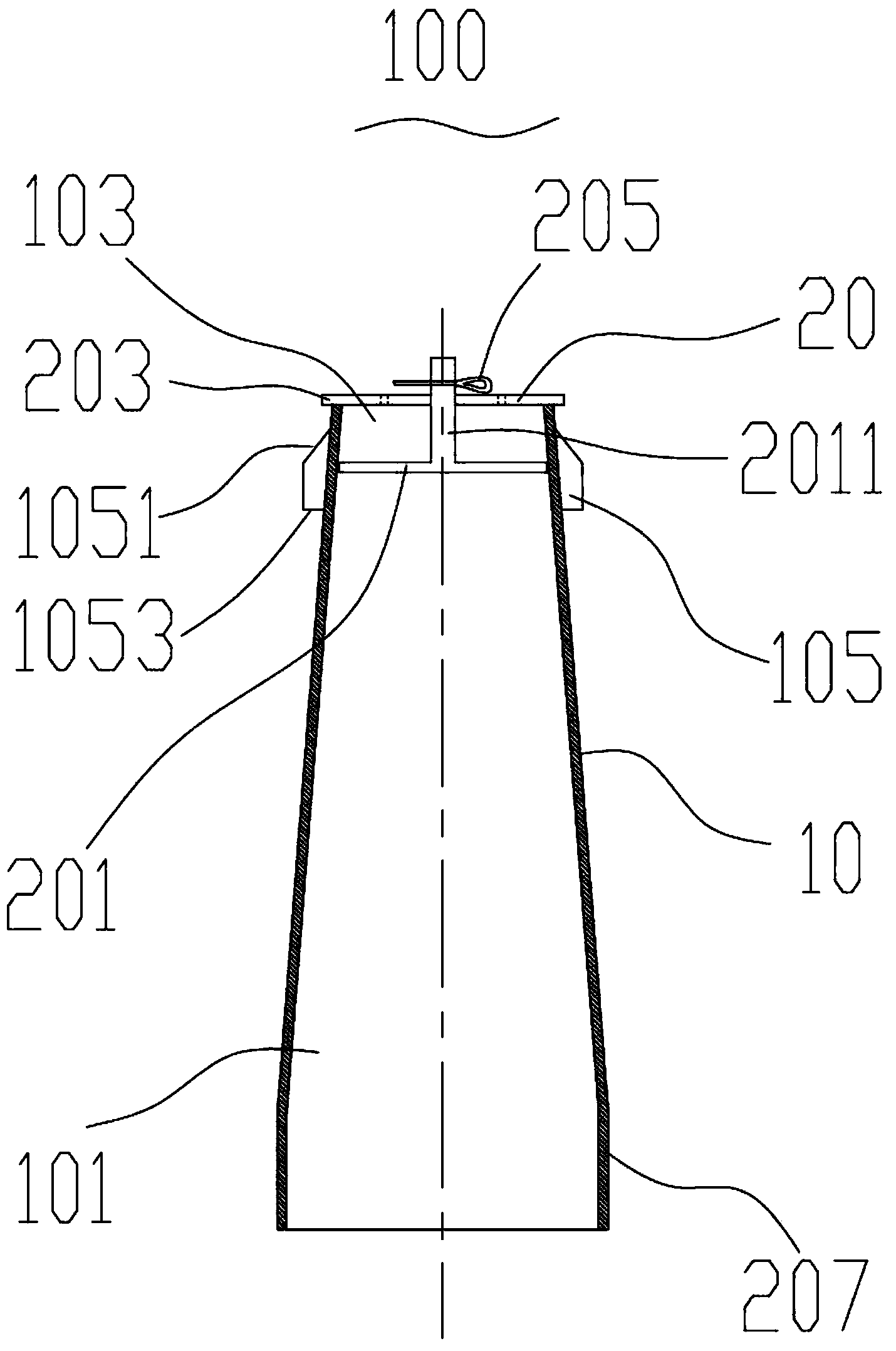

[0020] see Figure 1 to Figure 3 , the structure and content of the invention of the magnesium crystallizer 100 of the present invention will be described below with reference to the accompanying drawings.

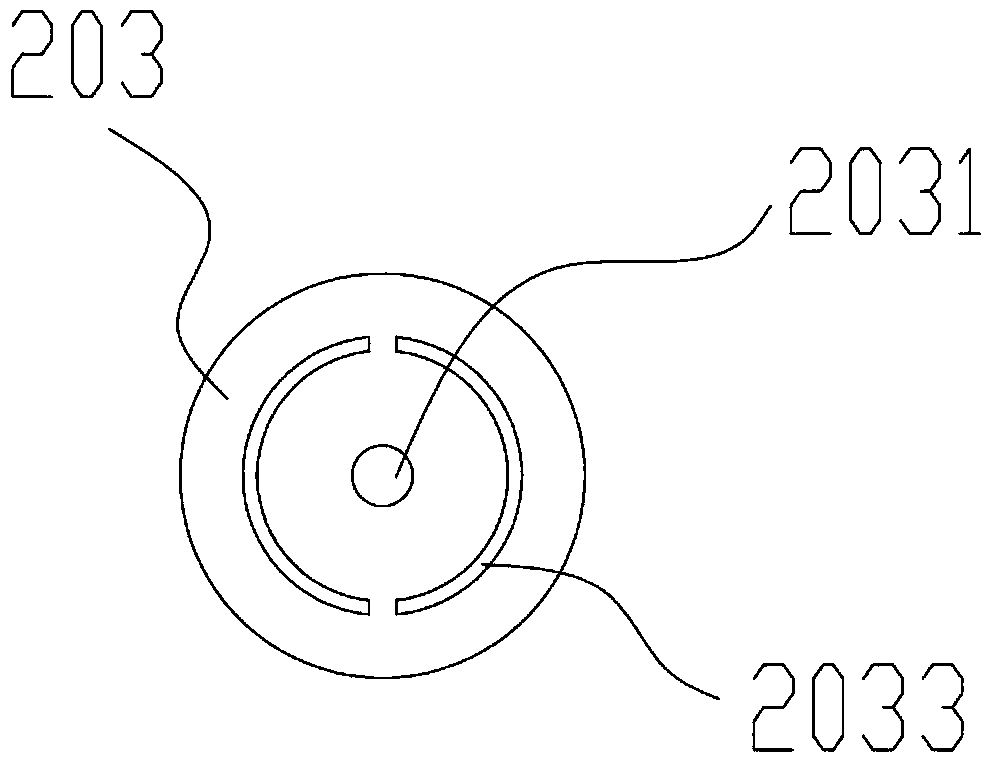

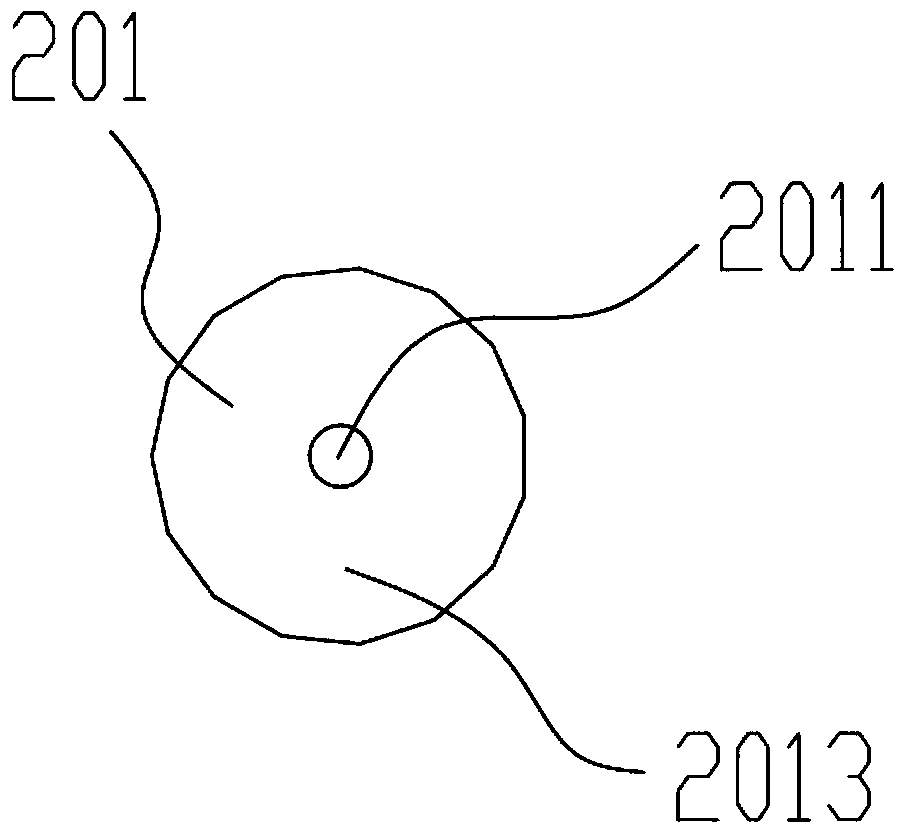

[0021] The magnesium crystallizer 100 of the present invention includes a conical cylinder 10 with a large mouth 101 and a small mouth 103 and an end cap 20 assembled at one end of the small mouth 103 of the conical cylinder 10. The large mouth 101 of the cylindrical body is loaded into the sealing plate 201 inside the small mouth 103 and the escape plate 203 outside the small mouth 103 is loaded from the outside of the tapered cylinder 10. The large mouth 101 of the tapered cylinder 10 is also connected with a straight cylinder part 207, the tapered The total length of the cylinder body 10 and the straight cylinder portion 207 is between 690mm-730mm, the diameter of the small opening 103 is between 190mm-220mm, the taper of the tapered cylinder body 10 is between 7°-10°, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com