A kind of splicing method of leather material and leather goods

A technology for leather materials and leather goods, which is applied to the seamless splicing method and the field of leather goods using the above-mentioned leather materials, which can solve the problems of decorative layer dislocation, falling off, cracking, etc., and achieve the connection without delamination, reducing waste, and firm connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

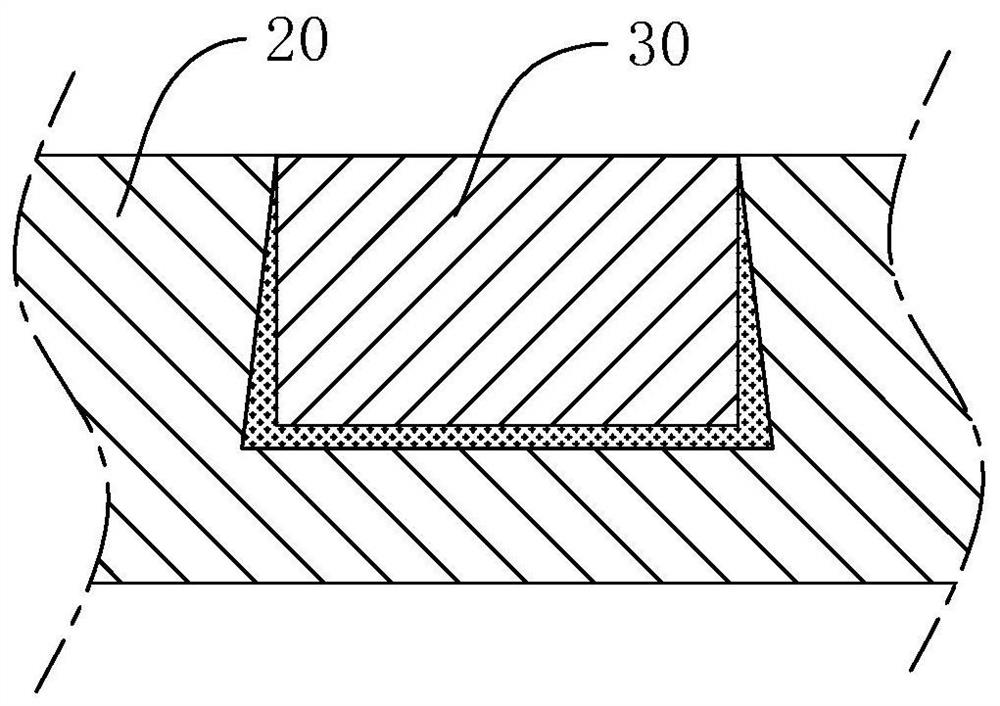

[0040] Get a large piece of cowhide as the main skin 20, the thickness of the main skin 20 is 2mm, take a paper grid as a reference, and the paper grid is a rectangle. Referring to the paper grid, process a strip-shaped slot with a depth of 1mm on the surface of the main leather 20; trim the edge of the matching leather 30 so that the matching leather 30 can just fit into the above slot, and the matching leather 30 The thickness is 0.8mm; trim the long strip of hot melt adhesive that can be placed in the slot. The thickness of the hot melt adhesive is 0.4mm. When the hot melt adhesive is not unpacked, it is usually wrapped temporarily with adhesive paper.

[0041] Finish the edge of the slot, use an oblique knife to cut across the side of the slot, and process an inclined cut. The angle of the cut can be 50-80°.

[0042] Preheat the hot melt adhesive with an iron at 50°C for 10 seconds, and put the hot melt adhesive into the slot. Lay four strips of smooth cardboard around th...

Embodiment 2

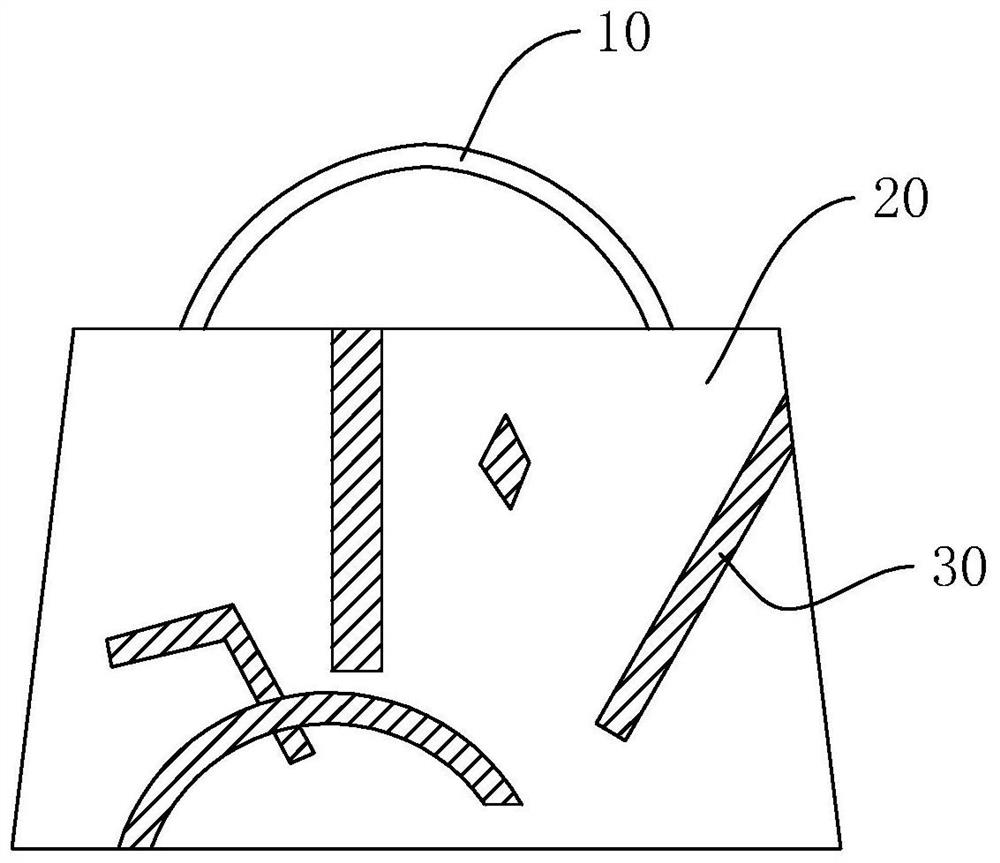

[0046] Get a large piece of cowhide as the main skin 20, the thickness of the main skin 20 is 3mm, get some paper grids as reference objects, and the paper grids have broken lines, arcs and rectangles. With reference to each paper grid, slots with a depth of 2mm are machined at different positions on the surface of the main leather 20 with a shovel knife. The shapes of the slots are respectively broken lines, arcs and rectangles. figure 2 The slot in the upper right corner of the front of the leather goods (with leather 30) is an isolated island, and the slot in the lower left corner of the front of the leather goods (with leather 30) is in contact with each other. Trim the edges of several matching skins 30, so that each matching skin 30 can be embedded in the corresponding slot, and the thickness of all matching skins 30 is 1.7mm. Trim several strips of hot melt adhesive that can be put into the slot. The thickness of the hot melt adhesive is 0.5mm. When the hot melt adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com