Shock-absorbing member and washing machine

A technology for washing machines and shock parts, which is applied in the field of washing equipment, can solve problems such as inability to adjust the damping force, single damping force, and large vibration noise, so as to improve the stability of shock absorption, ensure the stability of the whole machine, and reduce vibration noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

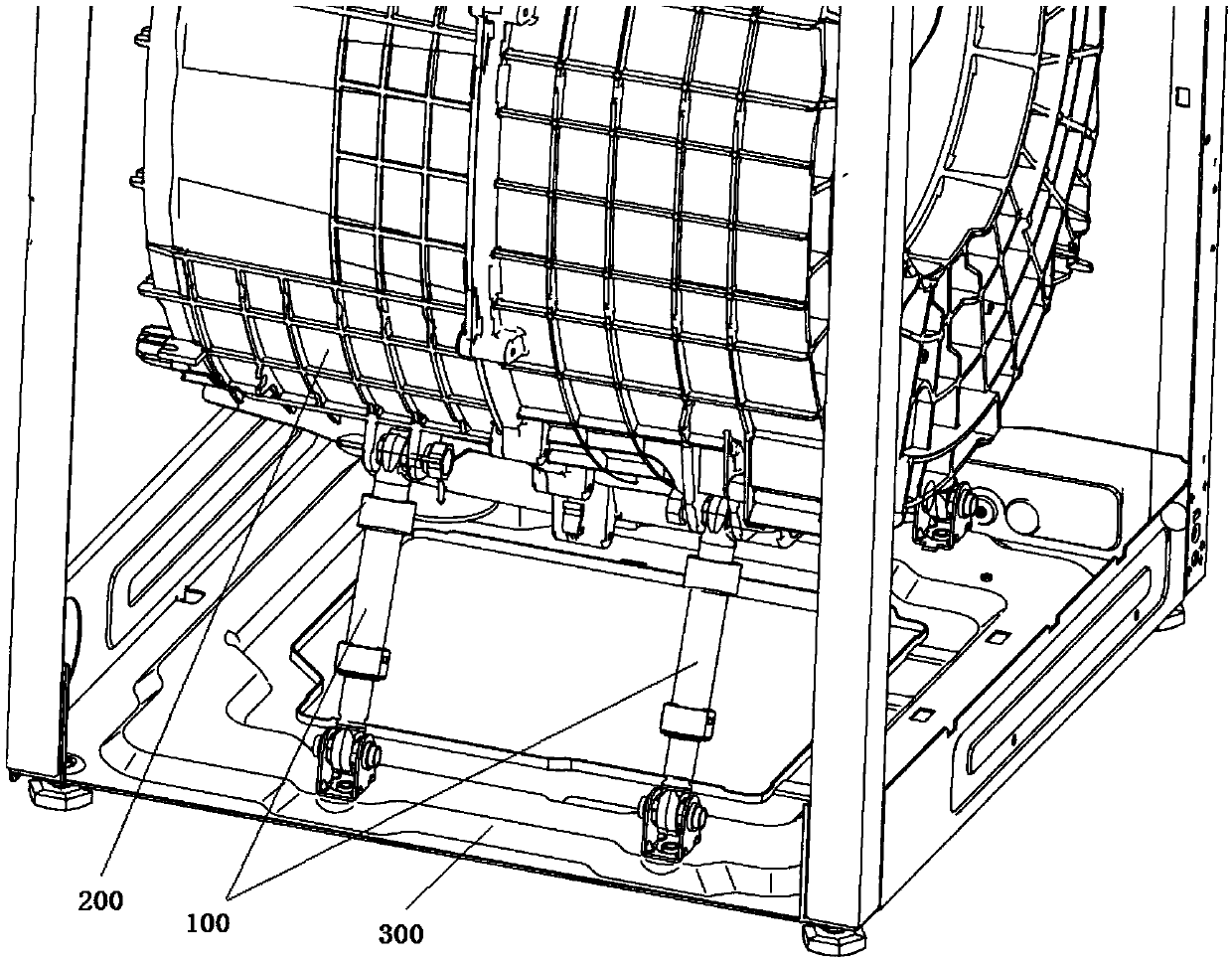

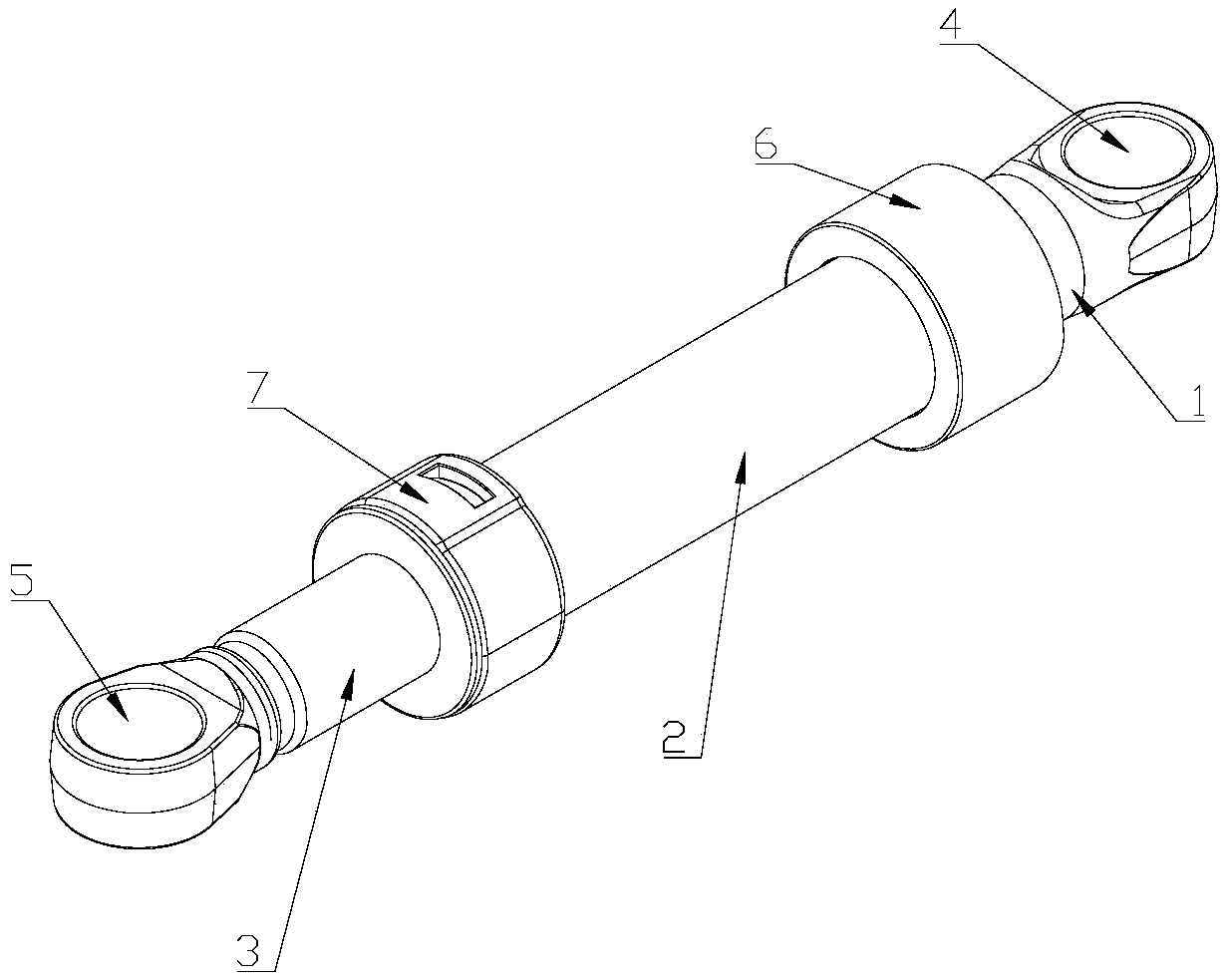

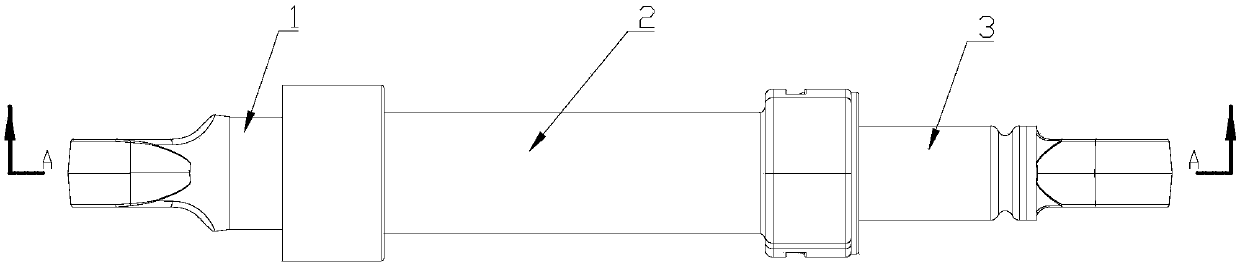

[0050] Such as Figure 2 to Figure 4 As shown, this embodiment introduces a shock absorber for a washing machine, which includes: a first-stage shock absorber 1, a second-stage shock absorber 2, and a third-stage shock absorber that are formed of a sleeve structure and inserted in sequence. 3. The lower end of the primary shock absorbing rod 1 is inserted from the upper end of the secondary shock absorbing rod 2, the upper end of the third stage shock absorbing rod 3 is inserted from the lower end of the secondary shock absorbing rod 2, and damping members are respectively provided at the two sockets.

[0051] By setting the shock absorbing rods which are composed of sleeve structures and inserted into each other in sequence, the adjacent shock absorbing rods are radially limited through the joints, and the vibration transmitted by the water tank acts on the plugging of the shock absorbing rods. In the direction, the damping members at the joints of the adjacent shock absorbin...

Embodiment 2

[0060] The difference between this embodiment and the above-mentioned embodiment 1 is: as Figure 5 As shown, in this embodiment, the damping structure at the insertion joint of the primary shock absorbing rod 1 and the secondary shock absorbing rod 2 is composed of a hydraulic damping structure and / or a pneumatic damping structure.

[0061] Such as Figure 5 As shown, in this embodiment, the upper end of the secondary shock absorbing rod 2 is correspondingly inserted into the annular cavity 6 protruding from the lower end of the primary shock absorbing rod 1. The lower side of the annular cavity 6 is provided with a circle of annular gaps, and the annular cavity 6 The opening of the gap and the joint of the secondary damping rod 2 are sealed to form a closed chamber; the end of the secondary shock absorbing rod 2 inserted into the annular cavity 6 is provided with a radially protruding ring An annular rib 8, so that the joint of the secondary shock absorber rod 2 and the pri...

Embodiment 3

[0066] The difference between this embodiment and the above-mentioned embodiment 1 is: as Figure 6 As shown, in this embodiment, the damping structure at the insertion joint of the primary shock absorbing rod 1 and the secondary shock absorbing rod 2 is composed of a shock absorbing spring.

[0067] Such as Figure 6 and Figure 7 As shown, in this embodiment, the upper end of the secondary shock absorbing rod 2 is correspondingly inserted into the annular cavity 6 protruding from the lower end of the primary shock absorbing rod 1. The lower side of the annular cavity 6 is provided with a circle of annular gaps. The upper end of the shock rod 2 is inserted into the annular cavity 6 from the opening of the annular cavity 6 . The end of the secondary damping rod 2 inserted into the annular cavity 6 is provided with a radially protruding circle of annular ribs 8, and the first spring 12 and the annular ribs are clamped between the annular ribs 8 and the upper side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com