Piston pump with first opening and first closing sealing structure

A sealing structure, piston pump technology, applied in pump components, variable volume pump components, liquid variable volume machinery, etc., can solve the problems of efficiency loss, restricting the efficiency of high-speed operation of the piston pump, and inability to enter immediately, to prevent EFFECT OF EFFICIENCY LOSS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

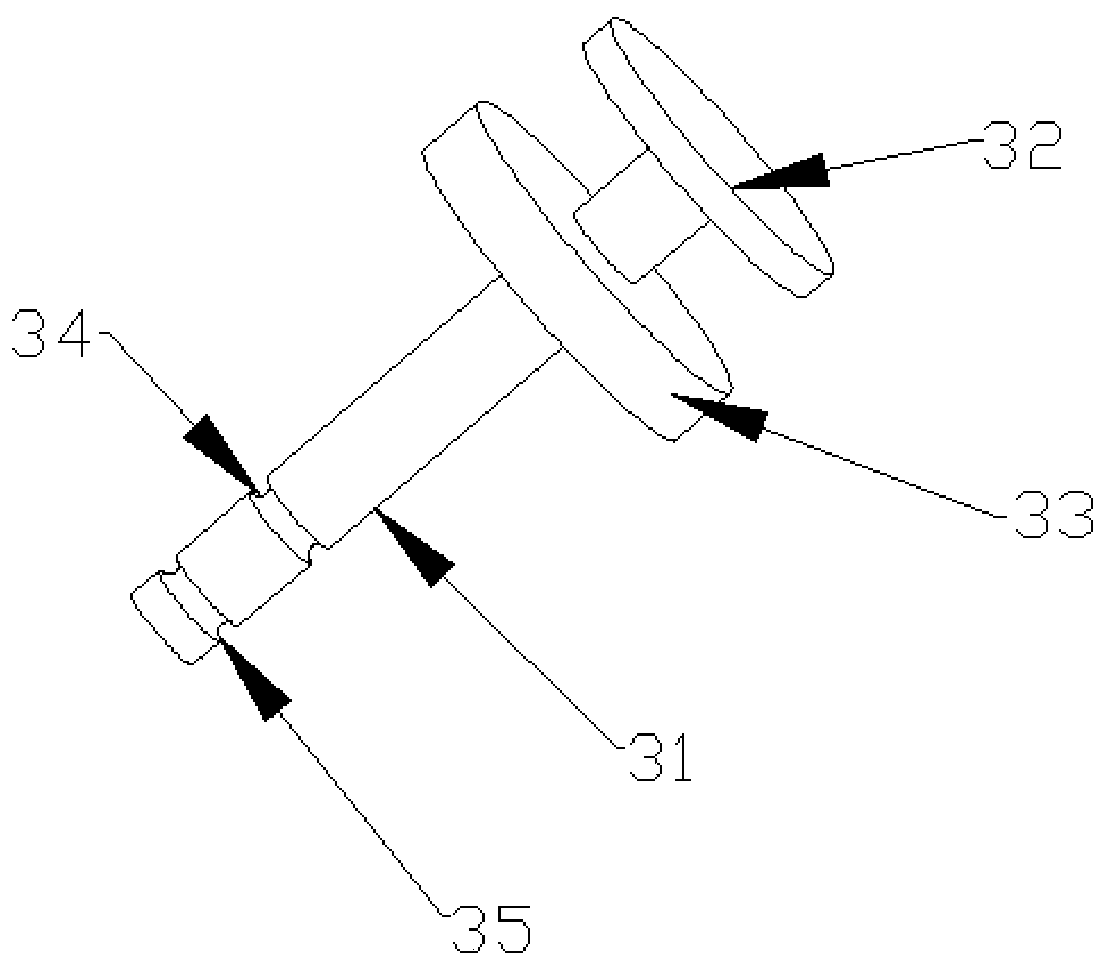

[0056] Embodiment two: if Figure 10 and Figure 11 As shown, the difference of this embodiment is that an elastic component 9 is arranged on the driving member, and the process of its air intake and exhaust is the same as that of the first embodiment. Specifically, a piercing groove 52 for the sealing rod 31 to penetrate is provided in the middle of the driving member 5, spring grooves 55 are symmetrically arranged on both side walls of the piercing groove 52, and the elastic assembly 9 includes a spring 91 arranged in the spring groove 55. , The end of the spring 91 is provided with a ball 92 . When the sealing rod 31 of the drive member 5 is moving, the ball 92 first abuts against the first locking position 34, and when the first sealing block 32 abuts against the partition plate 21, the movement of the entire sealing assembly 3 is restricted. When the driving member 5 continues to move downward, the spring 91 is squeezed by the spheroid 92, and the spheroid 92 is disenga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com