Heat accumulating type based incineration integrated equipment capable of circularly treating waste gas

A cyclic treatment, regenerative technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of increasing equipment cost, complex structure, low incineration efficiency, etc., to achieve convenient maintenance, improve anti-clogging ability, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

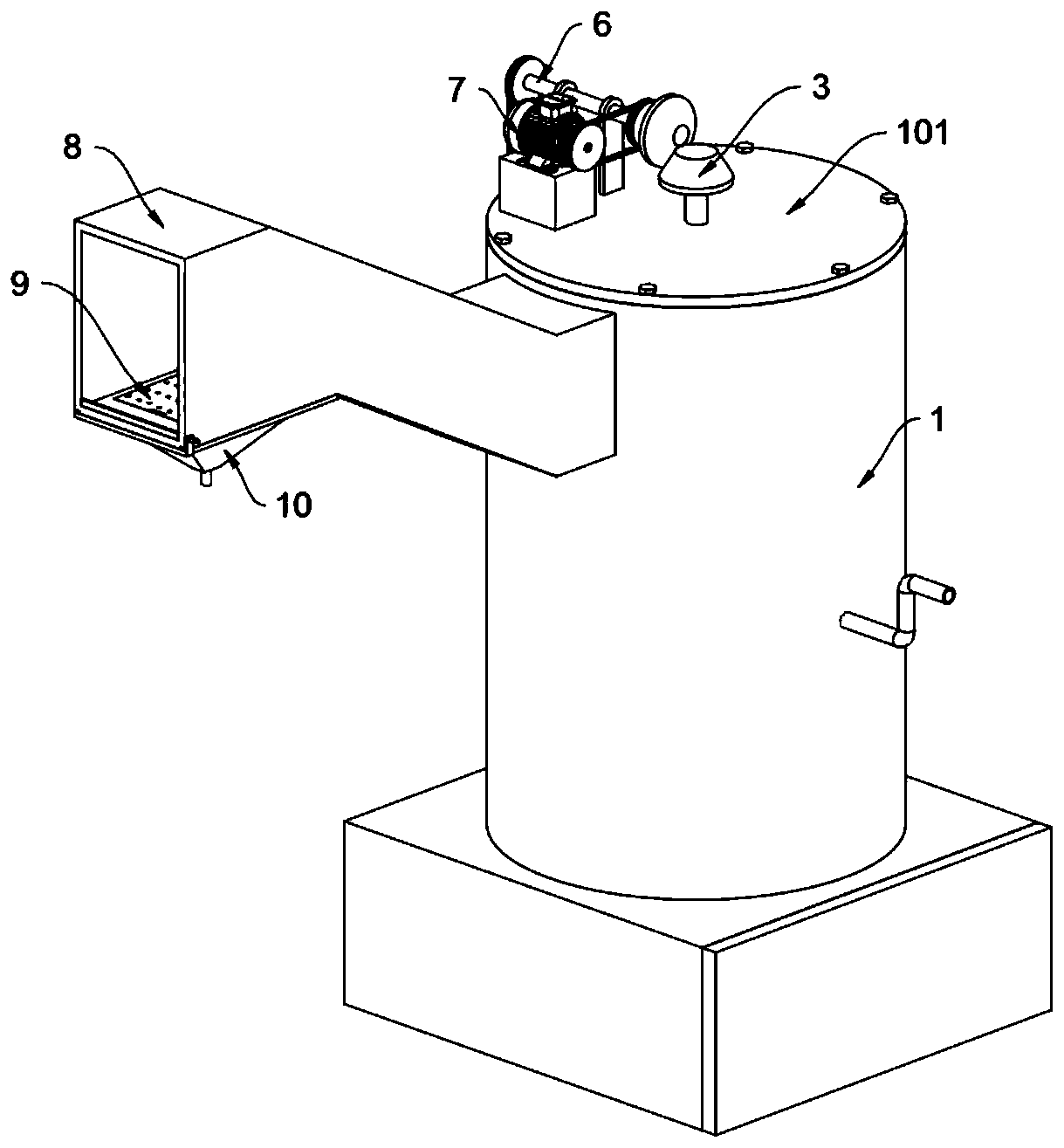

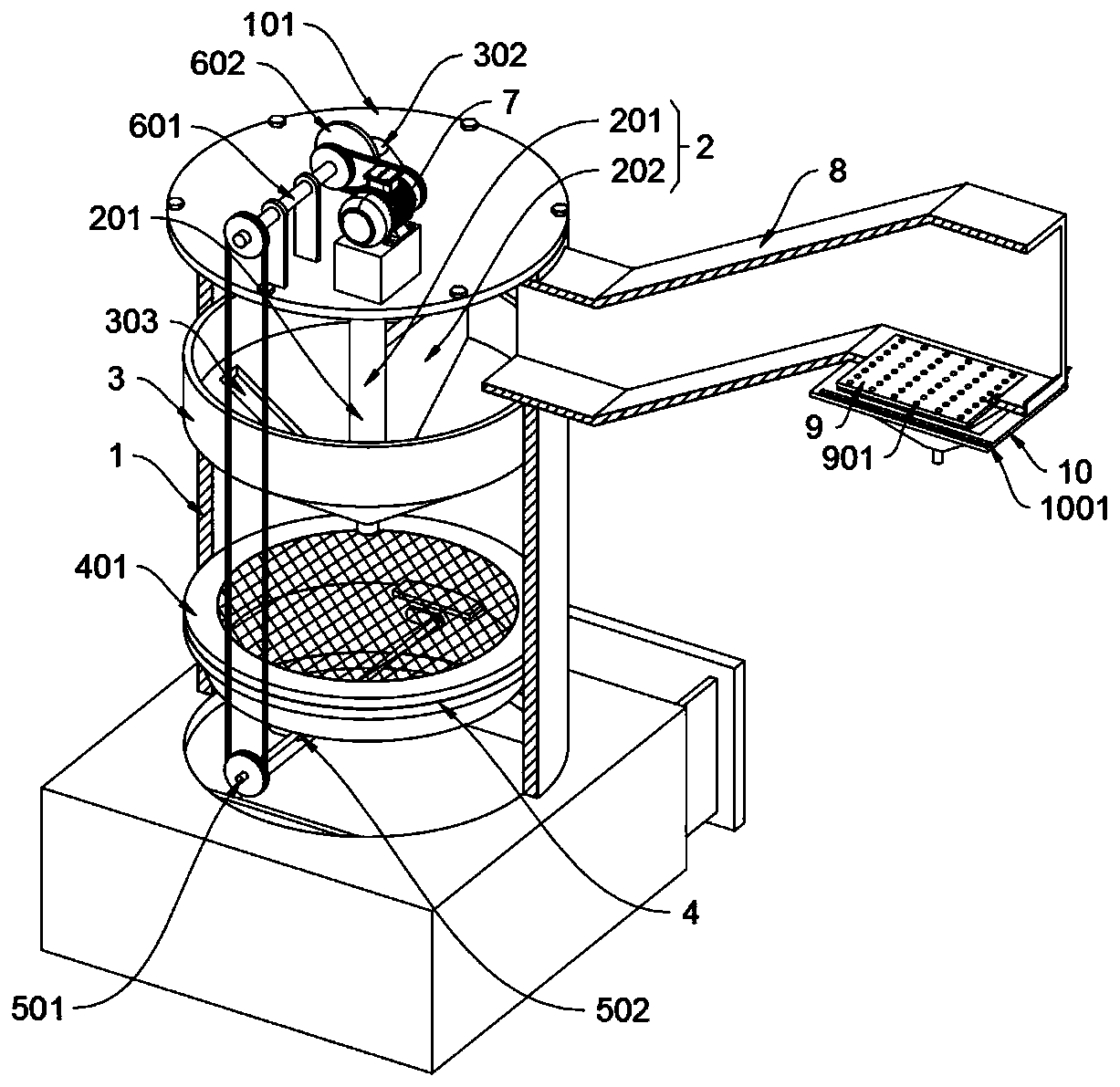

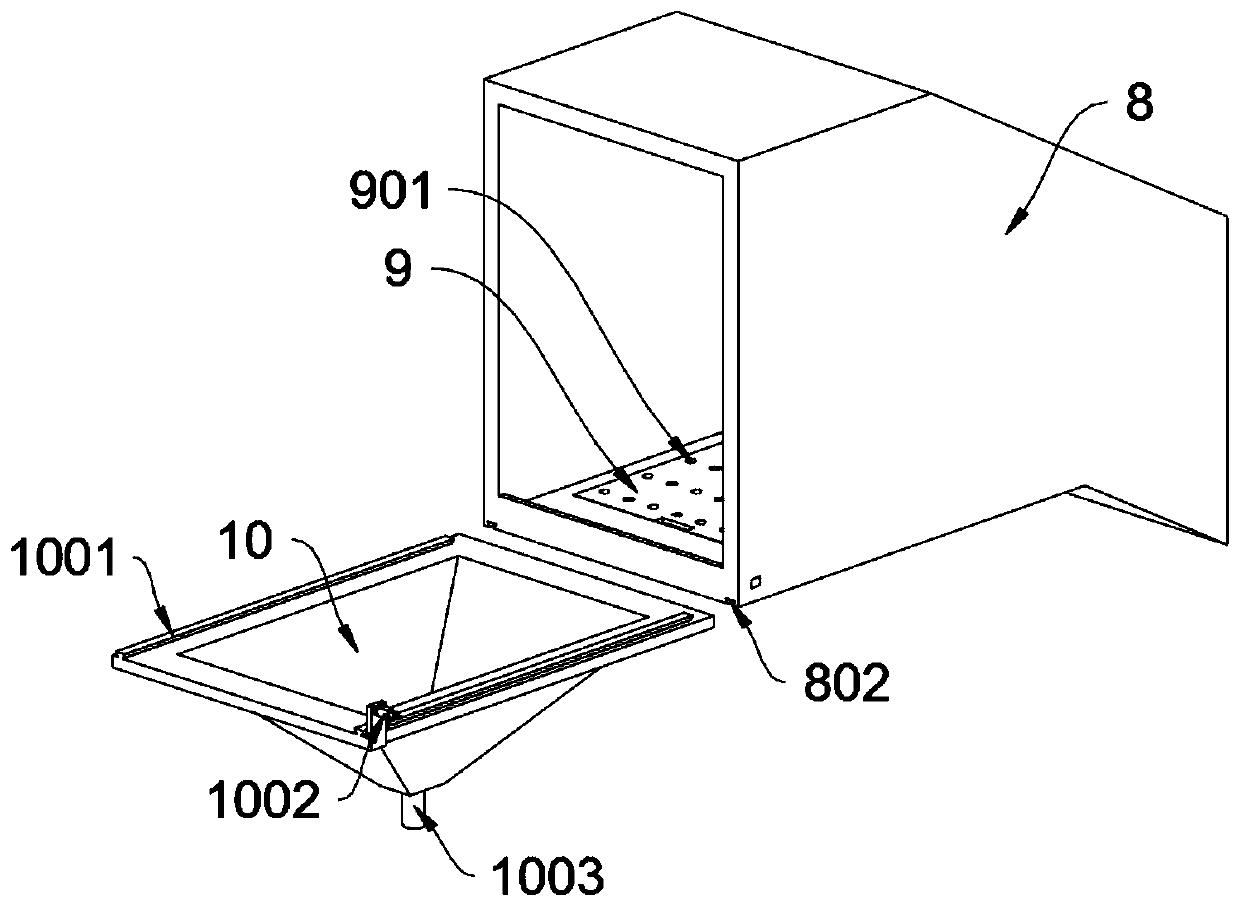

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The present invention provides an integrated incineration equipment based on thermal storage and recyclable waste gas treatment, which includes an incineration bucket 1; A retaining ring 4 is welded inside the barrel 1; a vibration structure 5 is rotatably connected to the incineration barrel 1, and a transmission structure 6 is rotatably connected to the incineration barrel 1, and a servo motor 7 is fixedly connected to the incineration barrel 1 by bolts; refer to for example Figure 7 , the retaining ring 4 includes an incineration frame 401, the retaining ring 4 is a circular structure, and the incineration frame 401 is sleeved in the retaining ring 4, and the incineration frame 401 is provided with a supporting net; the vibration structure 5 includes a rotating shaft A501 and a dial Block 502, the rotating shaft A501 is connected to the incineration bucket 1 in rotation, and two toggle blocks 502 are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com