Airtightness detection system of pressure vessel

A technology for air tightness detection and pressure vessels, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and detecting the appearance of fluid at the leakage point, etc. It can solve improper sealing at the interface, complex clamping tool structure, Inconvenient use and maintenance, etc., to achieve the effect of low cost, good sealing effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

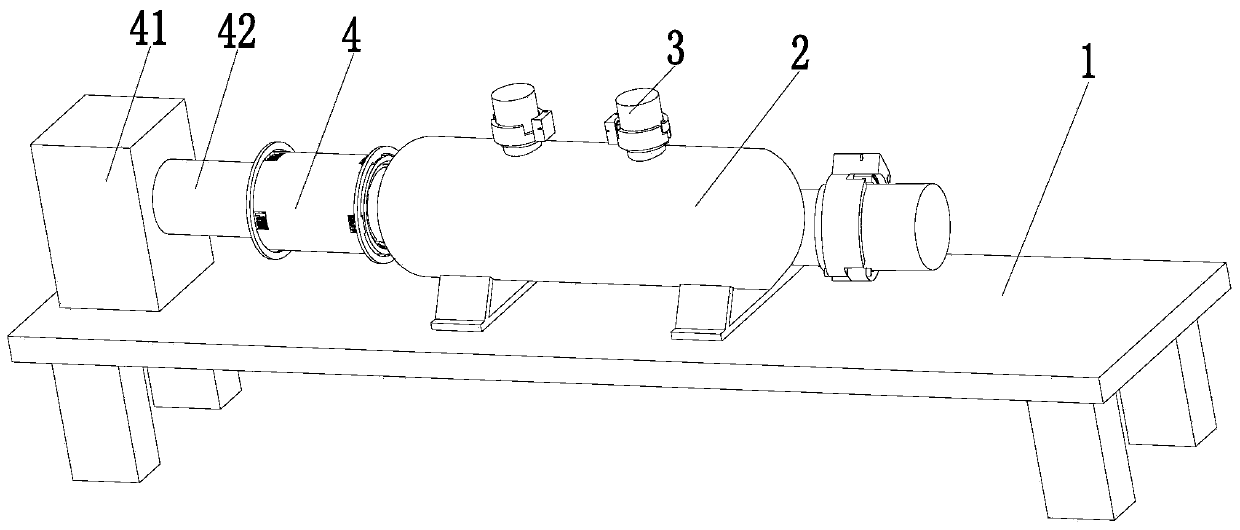

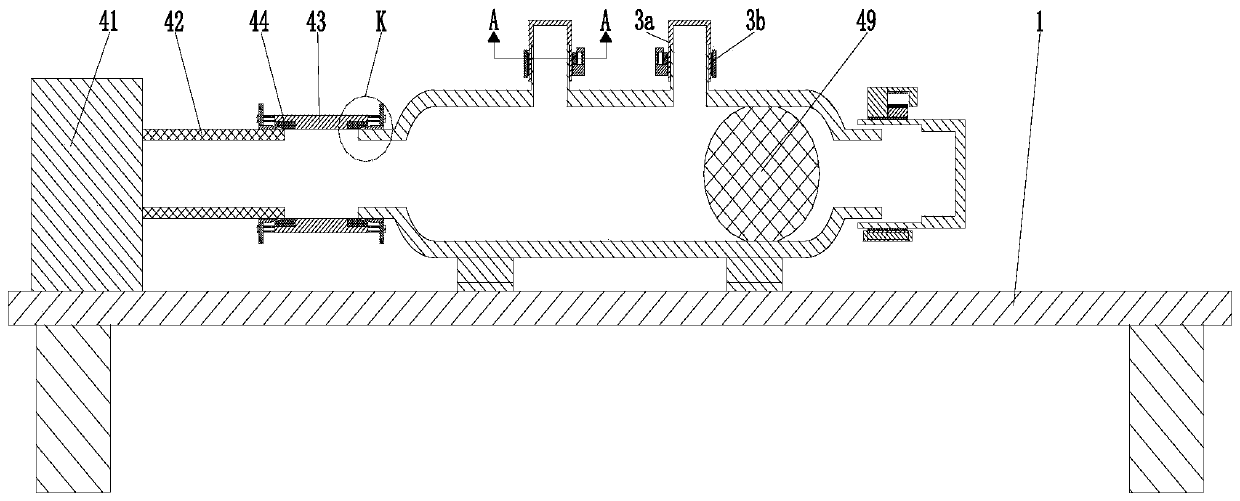

[0024] Such as Figure 1 to Figure 6 As shown, a pressure vessel airtightness detection system includes a test platform 1, a pressure vessel body 2, a sealing device 3 and a gas delivery device 4. The pressure vessel body 2 is placed on the test platform 1, and the test platform 1 A gas delivery device 4 is provided, and a sealing device 3 is connected to the upper end of the pressure vessel body 2 .

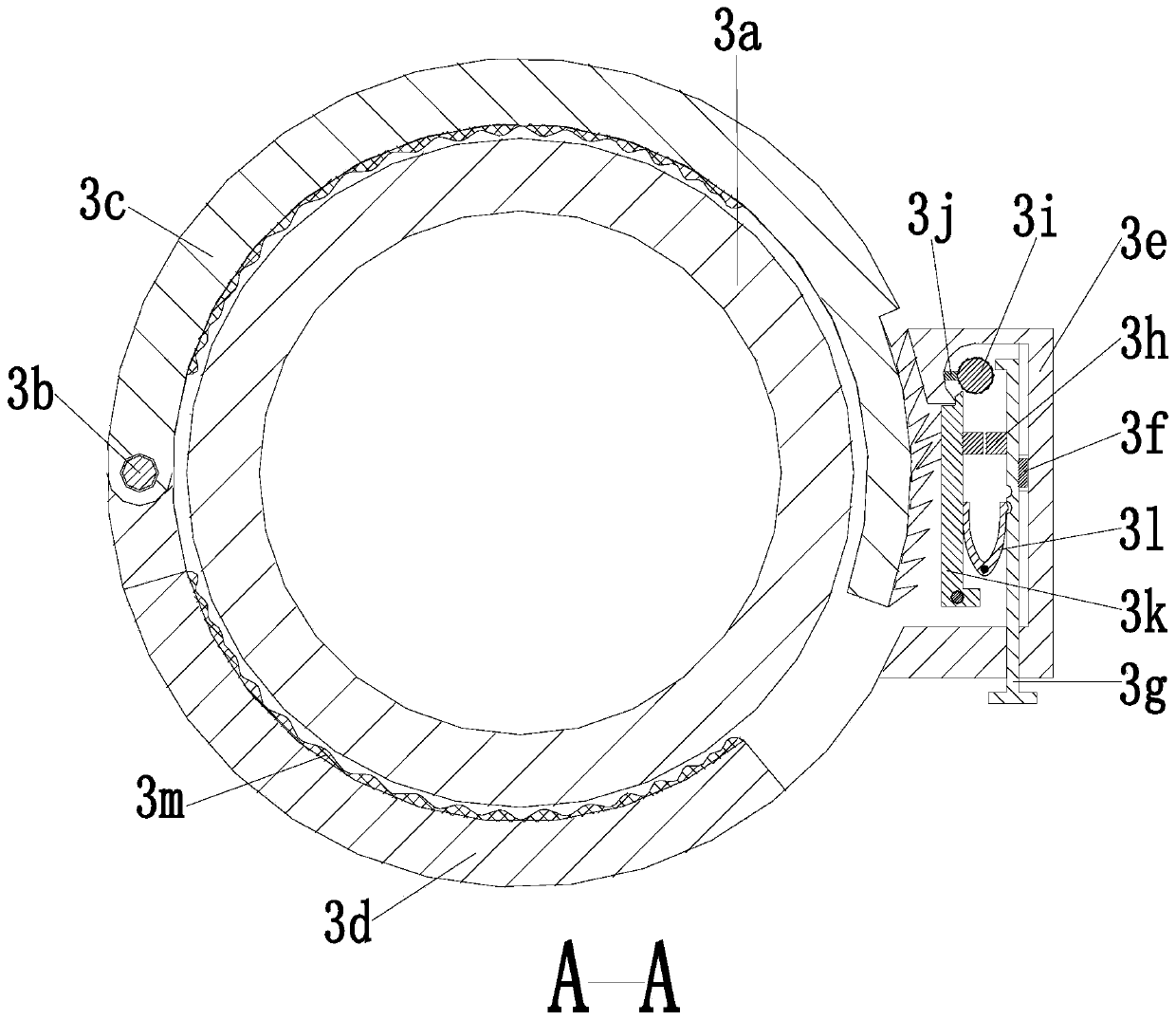

[0025] The sealing device 3 includes a sealing tube 3a, a connecting rod 3b, a locking half ring 3c, an unlocking half ring 3d, a locking plate 3e, a slider 3f, a positioning rod 3g, a top block 3h, a rotating rod 3i, Push rod 3j, locking rod 3k, U-shaped shrapnel 3l and rubber plate 3m, the sealing pipe 3a is sleeved on the air inlet at the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com