Milky tea and making method thereof

A technology of milk tea and tea leaves, which is applied in the field of milk tea and its preparation, which can solve the problems of liquid splashing, uneven stirring, and short brewing time, and achieve the effects of maintaining a stable state, accelerating expansion, and consistent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1 selects the milk tea that black tea is made

[0079] A milk tea is made from the following raw materials in parts by weight: 50g of milk powder, 20g of brown sugar, 5g of black tea, and 350ml of water.

[0080] The production process includes the following steps:

[0081] Step 1, weigh 5g of black tea (Lapsang Souchong) according to the formula, add 350ml of hot water at 95°C and brew for 2 minutes to filter out the tea leaves to obtain tea liquid;

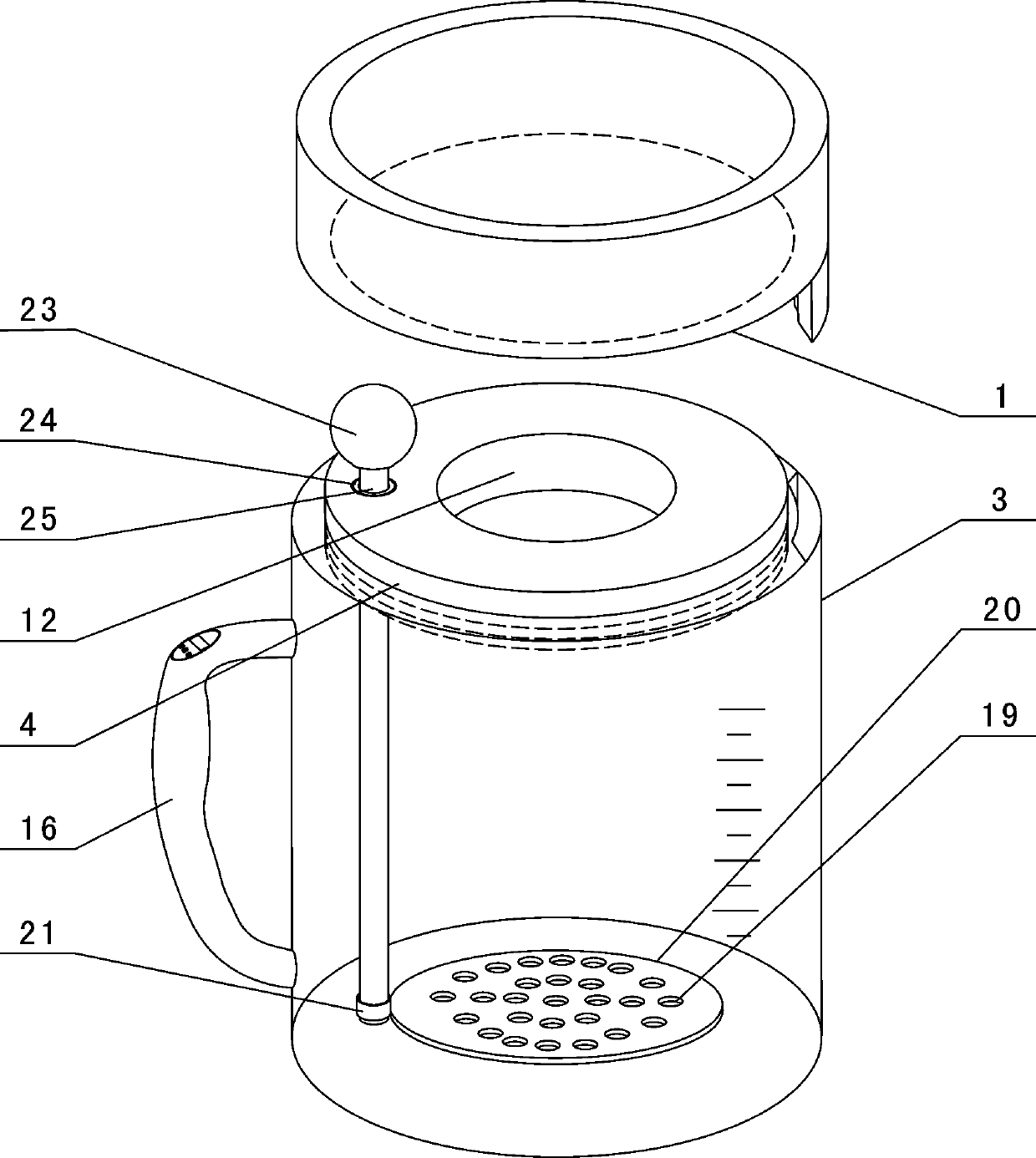

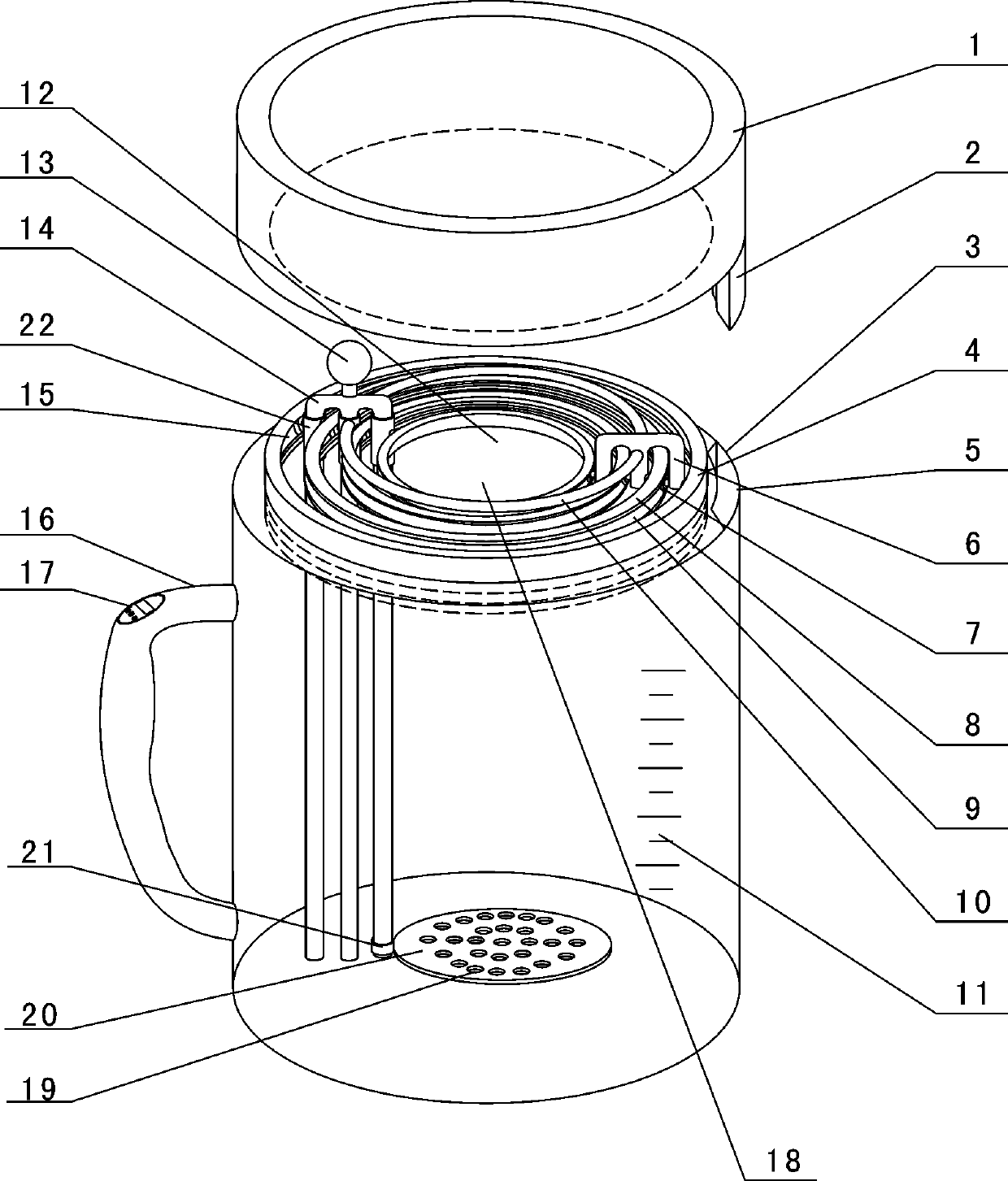

[0082] Step 2, weigh the milk powder and brown sugar according to the formula, and pour them into the pot body 3 from the feeding port 12;

[0083] Step 3, stir; hold the shaker 13 and turn the stirring fork 14 clockwise to stir for 1 min;

[0084] Step 4, pulling; repeatedly pulling the stirring fork 14 up and down, driving the disc 20 to move up and down, and the liquid shuttles back and forth through the through holes 19 on the disc 20 to realize the vortex rotation of the mixed liquid;

[0085] Step 5, t...

Embodiment 2

[0086] Embodiment 2 selects the milk tea that green tea is made for use

[0087] A milk tea is made from the following raw materials in parts by weight: 40g of milk powder, 20g of brown sugar, 5g of green tea, and 400ml of water.

[0088] The production process includes the following steps:

[0089] Step 1, take green tea 5g by formula quantity, add 400ml of hot water of 80 ℃ and brew for 2.5min to filter out tealeaves to obtain tea liquid;

[0090] Step 2, weigh the milk powder and brown sugar according to the formula, and pour them into the pot body 3 from the feeding port 12;

[0091] Step 3, stir; hold the shaker 13 and turn the stirring fork 14 clockwise to stir for 1 min;

[0092] Step 4, pulling; repeatedly pulling the stirring fork 14 up and down, driving the disc 20 to move up and down, and the liquid shuttles back and forth through the through holes 19 on the disc 20 to realize the vortex rotation of the mixed liquid;

[0093] Step 5, the hot drink type green tea ...

Embodiment 3

[0094] Embodiment 3 selects the milk tea that Pu'er tea is made for use

[0095] A milk tea is made from the following raw materials in parts by weight: 50g of milk powder, 20g of brown sugar, 5g of Pu'er tea, and 350ml of water.

[0096] The production process includes the following steps:

[0097] Step 1, take by weighing Pu'er tea 5g according to formula quantity, add 350ml of hot water of 85 ℃ and brew for 1.5min to filter out tealeaves to obtain tea liquid;

[0098] Step 2, weigh the milk powder and brown sugar according to the formula, and pour them into the pot body 3 from the feeding port 12;

[0099] Step 3, stir; hold the shaker 13 and turn the stirring fork 14 clockwise to stir for 1 min;

[0100] Step 4, pulling; repeatedly pulling the stirring fork 14 up and down, driving the disc 20 to move up and down, and the liquid shuttles back and forth through the through holes 19 on the disc 20 to realize the vortex rotation of the mixed liquid;

[0101] Step 5, the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com