Denitration inlet flue full-section flue gas mixer and method

A technology for mixing inlet flue and flue gas, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of unstable distribution rules, threats to safe and reliable operation of equipment, and difficulties in matching reducing agents and NOx to meet requirements, etc. problems, to achieve the effects of improving the uneven distribution of flue gas components, protecting safe and reliable operation, and reducing the level of ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

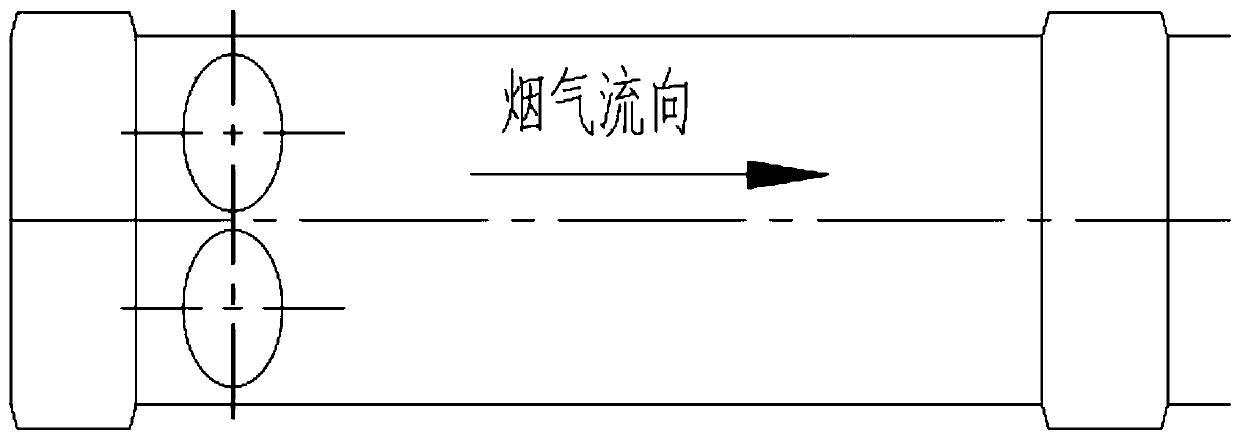

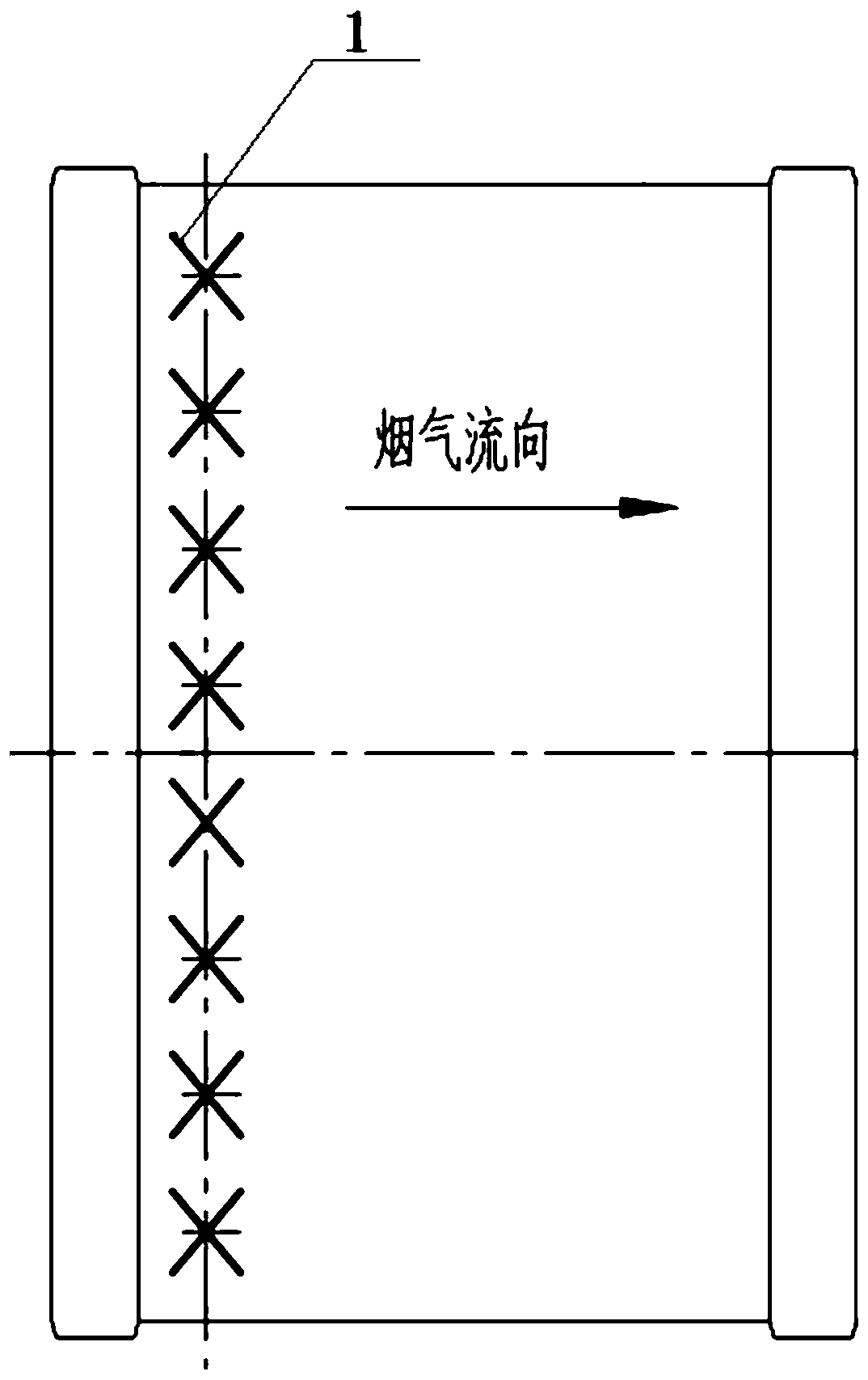

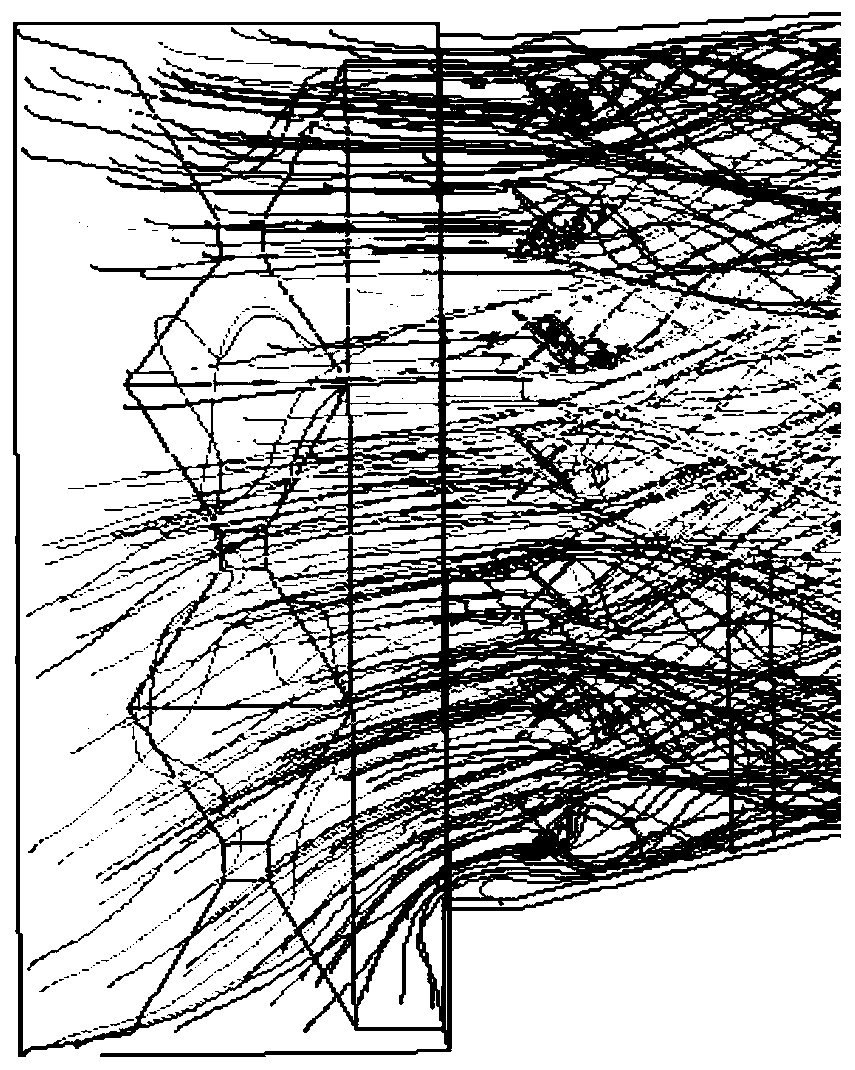

[0022] refer to figure 1 and figure 2 , the full-section flue gas mixer of the denitrification inlet flue according to the present invention includes several layers of deflectors 1 arranged on the cross section of the denitrification inlet flue and arranged in sequence along the height direction of the denitrification inlet flue, each deflector 1 facing left Skewing or skewing to the right, so that the flue gas of different layers cross-contacts and compulsively mixes in the whole section of the flue.

[0023] The number of deflectors 1 inclined to the left is the same as the number of deflectors 1 inclined to the right, and the deflectors 1 inclined to the right are alternately distributed with the deflectors 1 inclined to the right, and the shape of each deflector 1 is a disk .

[0024] The full-section flue gas mixing method of the denitrification inlet flue des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com