Cleaner with water spraying and automatic gas blowing functions

A cleaning device and automatic technology, applied in the field of cleaning devices, can solve the problems of general cleaning effect, limited use and high cost, and achieve the effects of good cleaning effect, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

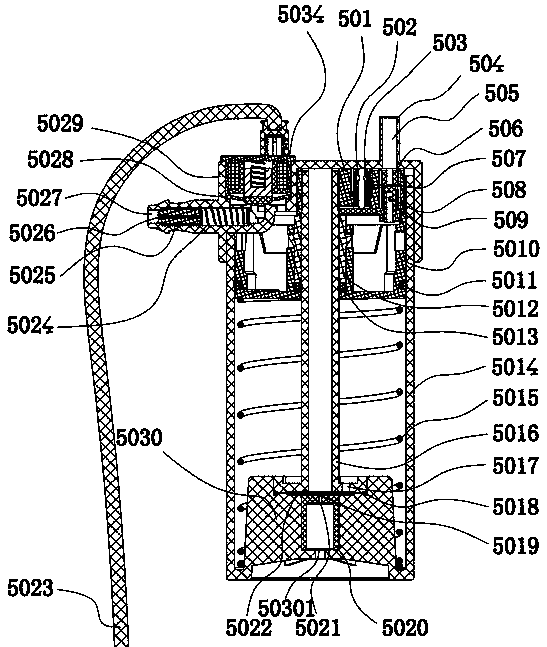

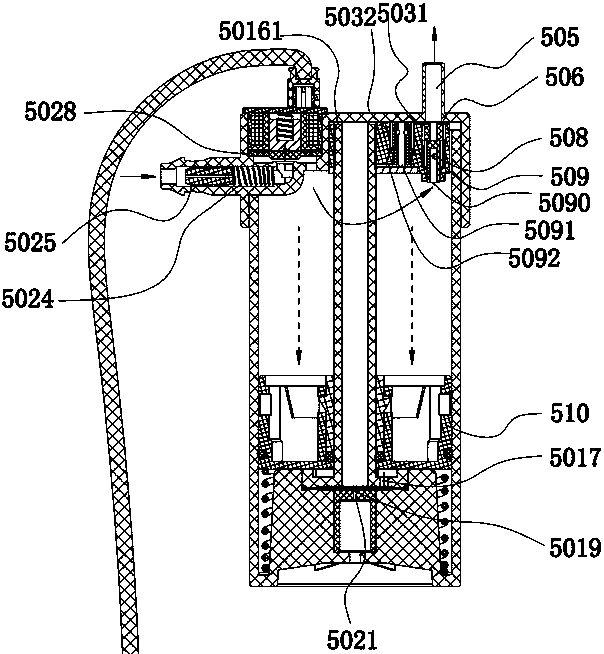

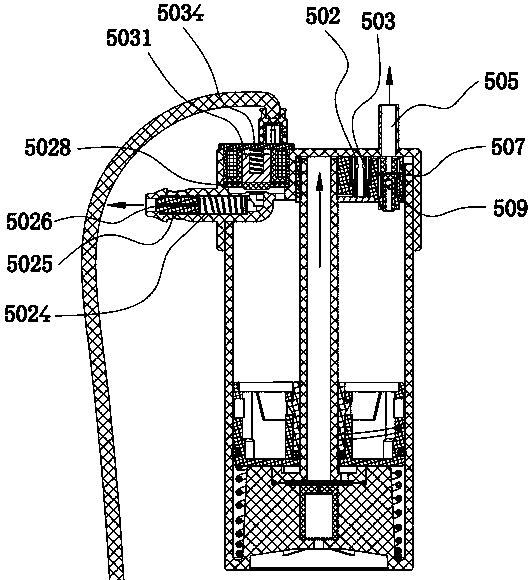

[0027] Such as figure 1 , figure 2 and image 3 As shown, the main body of the washer 50 is a cylinder, which includes a washer end cover 504 and a washer housing 5014 , and the washer end cover 504 is fixed on the washer housing 5014 .

[0028] A water inlet channel 5029 is set on the washer end cover 504, and one end of the water inlet channel 5029 is a water inlet 5027, which is connected to an external water inlet pipe for water intake through the water inlet 5027, and a solenoid valve 5034 is set at the other end of the water inlet channel, and through the solenoid valve 5034 The diaphragm 5028 opens or closes the other end of the water inlet channel.

[0029] The electromagnetic valve 5034 and the washer end cover 504 can be combined as one body or directly combined.

[0030] The above water inlet channel 5029 is equipped with a check valve core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com