Pipe type part drilling fixture

A technology for pipe parts and drilling fixtures, applied in metal processing machinery parts, clamping, manufacturing tools, etc., to achieve the effects of convenient operation, favorable clamping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but not limited thereto.

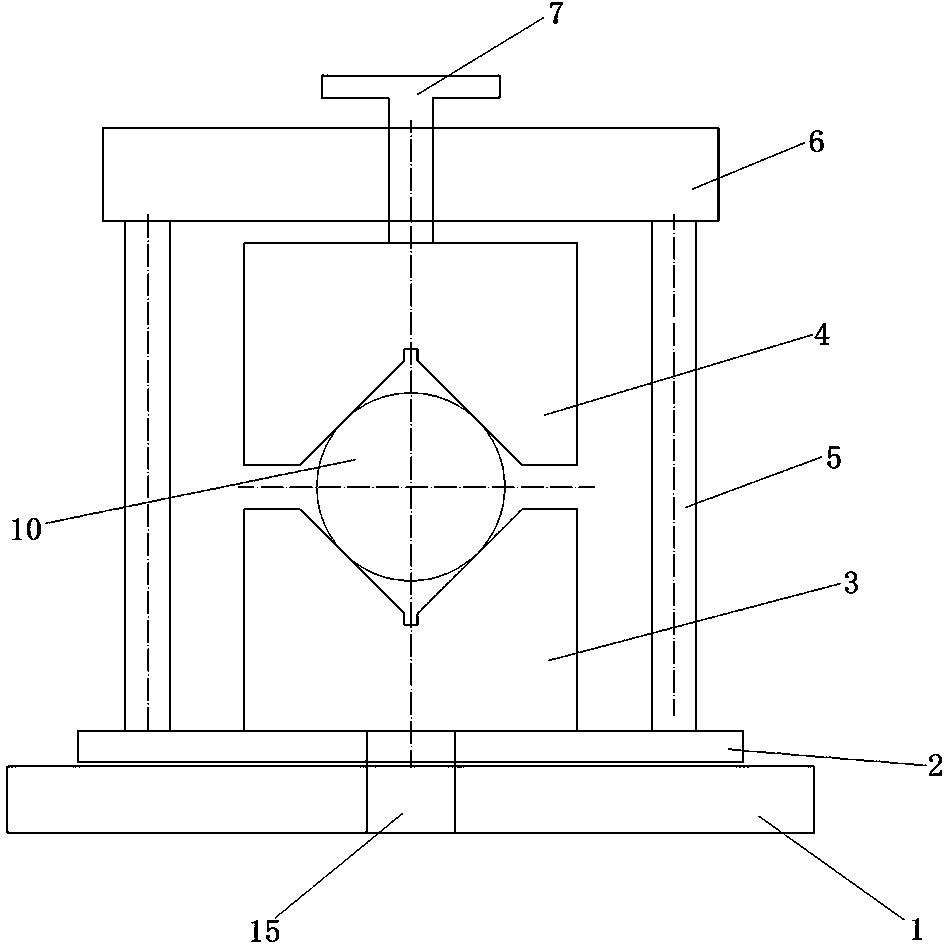

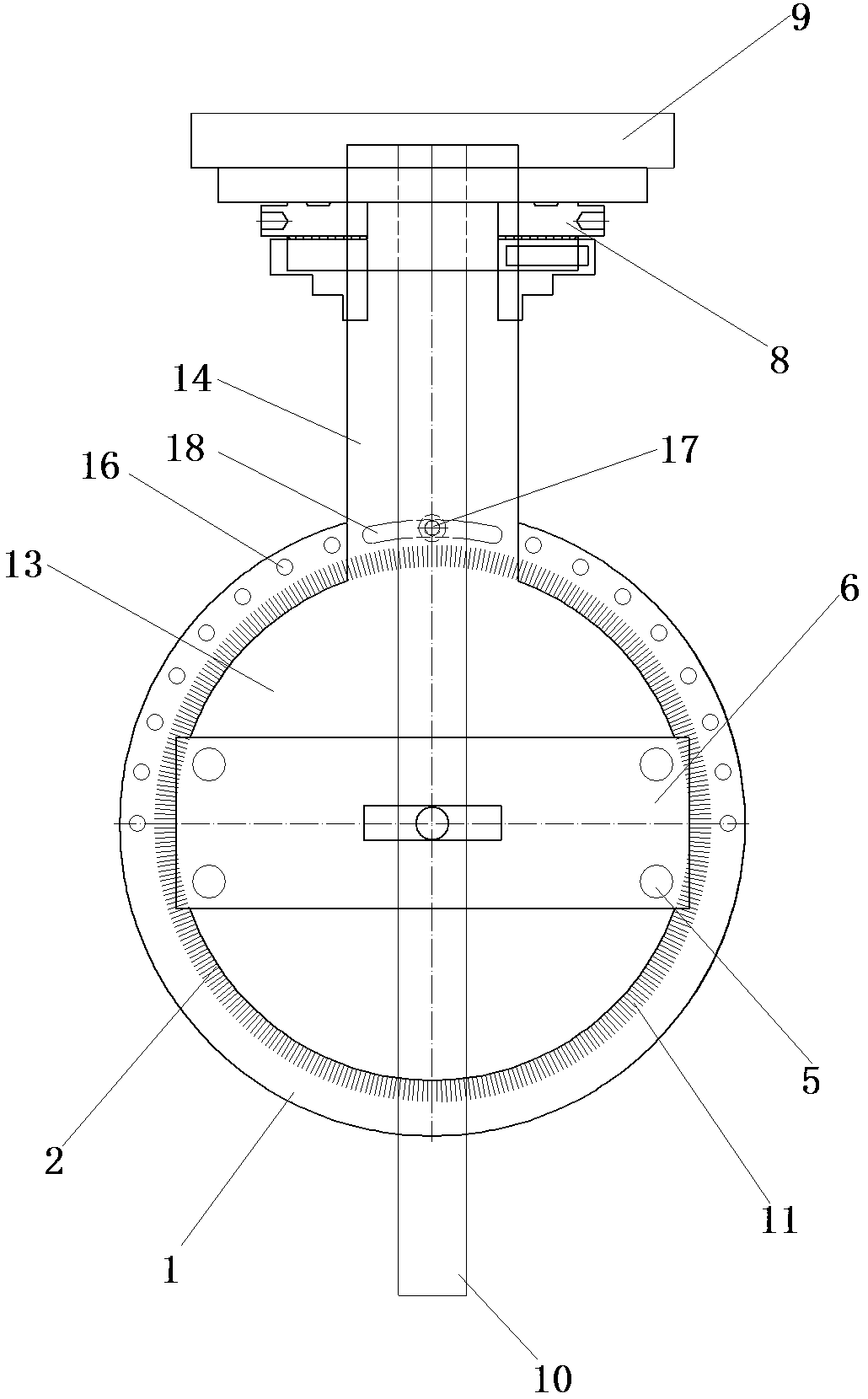

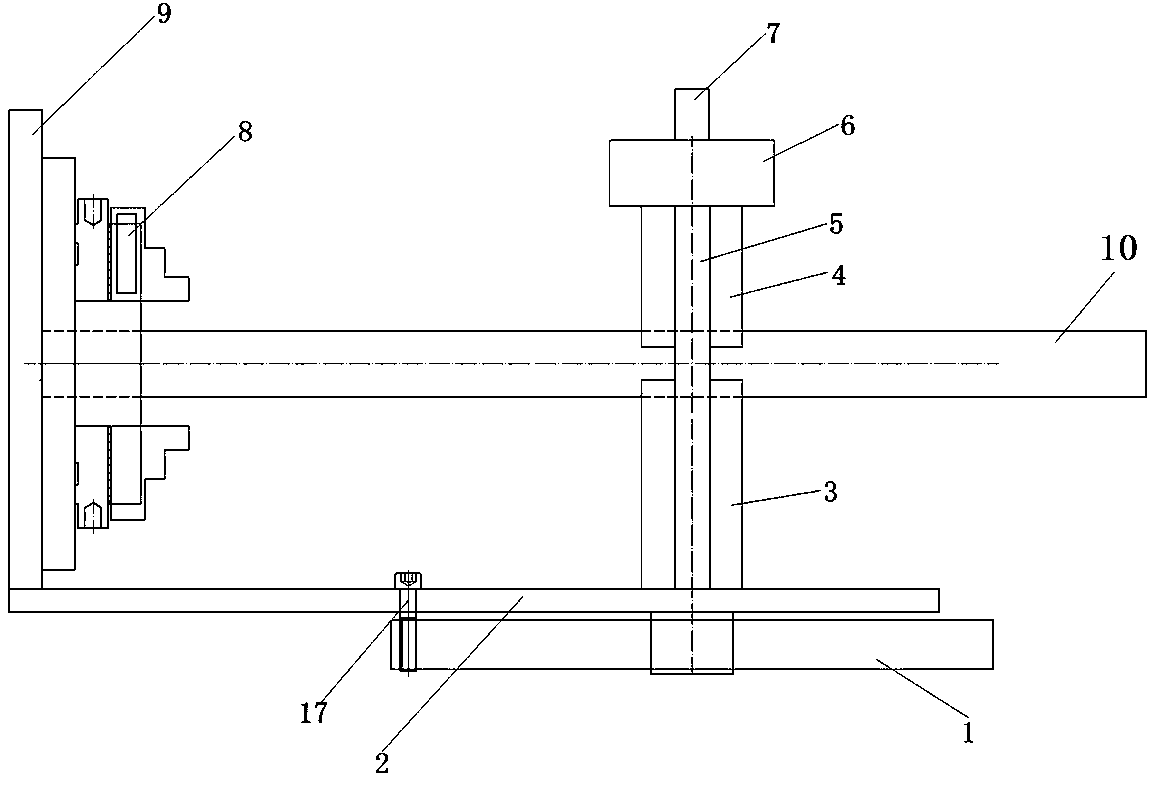

[0027] The specific embodiment of the pipe parts drilling jig provided by the invention is as figure 1 , figure 2 , image 3 with Figure 4 As shown, the drilling jig for pipe parts includes a base 1 fixed on a suitable machine tool 12 , on which a rotating frame 2 is arranged, and the rotating frame 2 is rotatably assembled on the base 1 through its own rotating shaft 15 . The base 1 is provided with a rotating scale 11 for measuring the rotation angle of the rotating frame 2 , and the base 1 is provided with positioning holes 16 arranged at intervals of half a circle outside the circumference of the rotating scale 11 . The swivel frame 2 includes a swivel seat 13 and an extension section 14 protruding outside the swivel seat 13 integrated with the swivel seat 13. The corresponding positioning hole 16 on the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com