A self-rotating optical fiber coating mask device and a coating method using the device

A self-rotation, optical fiber technology, applied in the field of optical fiber, can solve the problems such as the inability to realize the optical fiber mask process, the large size of the coating device, and the influence of the coating quality, and achieve the effect of realizing mass production, easy mass production, and solid structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

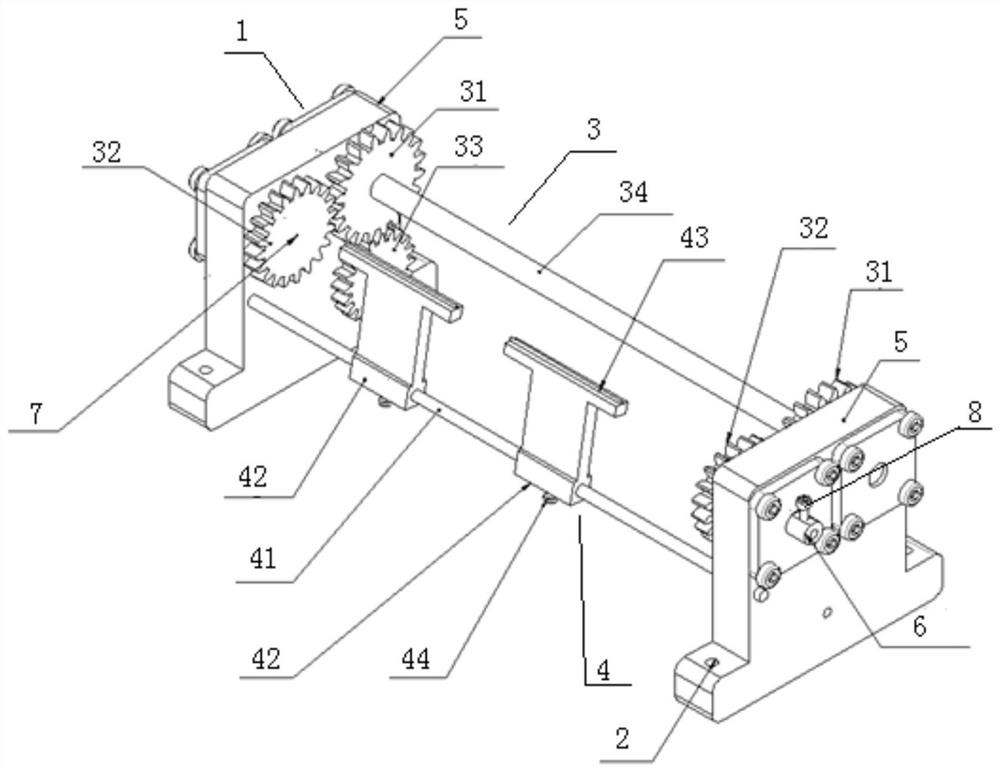

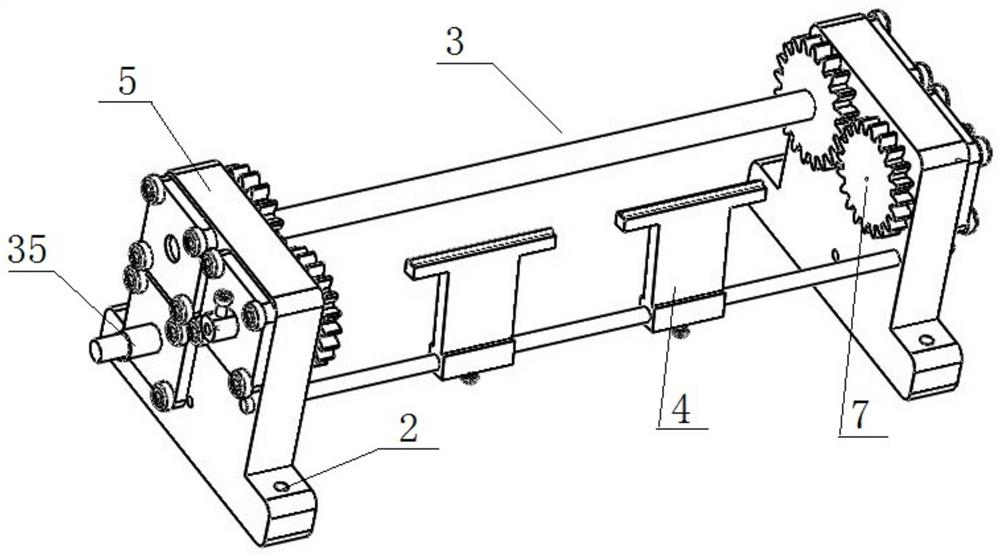

[0030] like Figure 1 to Figure 2 As shown, a self-rotating optical fiber coating mask device includes a fixed support structure 1, a drive structure 3 arranged on the fixed support structure 1 and used for optical fiber rotation, and a mask structure 4 for mask protection of the optical fiber during coating. The self-rotating optical fiber coating mask device in this embodiment has a uniform rotation speed during the coating process, and can uniformly sputter the film layer on the side of the optical fiber cylinder. The entire self-rotating optical fiber coating mask device has a separate closed structure, even if the The failure will not affect the environment of the coating chamber, the coating quality, and will not damage the coating device. The device is small in size and sturdy in structure, and is very suitable for a magnetron sputtering instrument with a small coating chamber space. The device is designed with a mask structure 4, which can realize a multi-film structu...

Embodiment 2

[0040] The present invention also provides a method for uniform coating on the side surface of an optical fiber cylinder, using the above self-rotating optical fiber coating mask device, including the following steps:

[0041] S1: Pass the optical fiber with the outer protective layer removed in sequence through the central hole 7 on the fixed shaft 6, the mask block through hole 43, and the central hole 7 on the fixed shaft 6, and fix both ends of the optical fiber to the driven gear through the screw structure 8 On the fixed shaft 6 on 32;

[0042] S2: Adjust the position of the mask block 42 on the support shaft 41, and perform mask protection on the optical fibers that do not require coating;

[0043] S3: Install the self-rotating optical fiber coating mask device in the chamber of the coating instrument;

[0044] S4: Turn on the instrument to evacuate. When the test requirements are met, turn on the stepper motor connected to the power take-off shaft 35 and adjust its sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com