Water-sealing-type composite impeller for cooling water pump of automobile engine

A technology for automobile engine and cooling water pump, which is applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of water absorption performance of water pump impellers in polluted environment, waste of materials, complicated structure, etc., and achieve material saving, simple structure, and water absorption. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

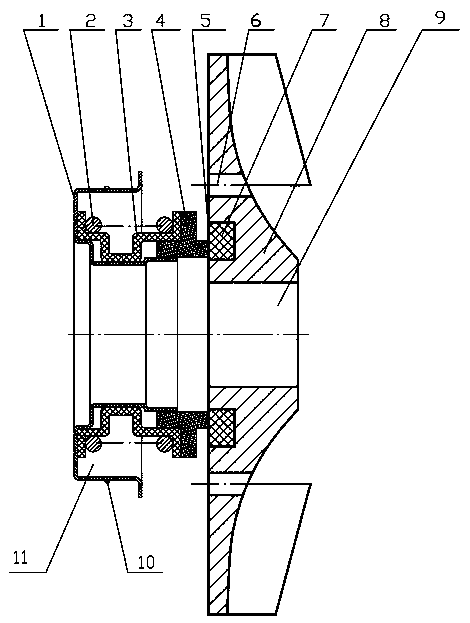

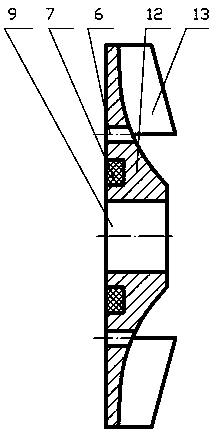

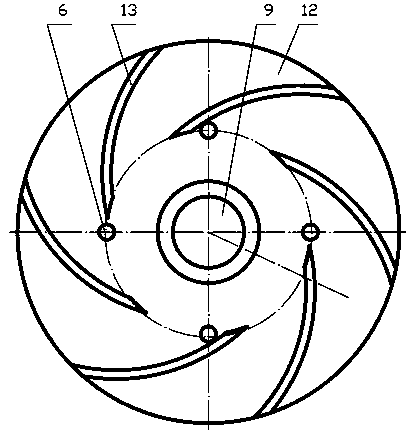

[0010] Embodiment: (see for details figure 1 ) A water-sealing type composite impeller for an automobile engine cooling water pump, which has a static ring seat 1, a corrugated rubber tube 3, a spring 2, a static ring 4 and an impeller 8, the outer wall of the static ring seat 1 is provided with a sealing ring 9, and the static ring The inner ring groove 11 of the seat 1 is fixedly equipped with a corrugated rubber tube 3, and a spring 2 and a static ring 4 are installed on the corrugated rubber tube 3. It is characterized in that the material of the impeller 8 is high-strength engineering plastic, and it is provided with spoke 12. The moving ring 7, the blades 13, the inner hole 9 and the balance hole 6. The moving ring 7 is made of silicon carbide material and embedded in the position corresponding to the spoke 12 of the impeller 8 and the static ring 4. The spoke 12 is smooth and smooth. The umbrella surface is provided with evenly distributed blades 13. When the water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com