Novel diameter measuring probe for pipeline detector

A detector and caliper technology, applied in instruments, measuring devices, etc., can solve problems such as reducing the accuracy of evaluation, inability to accurately determine the specific deformation amount and deformation position of the pipeline, and increasing the risk of internal detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

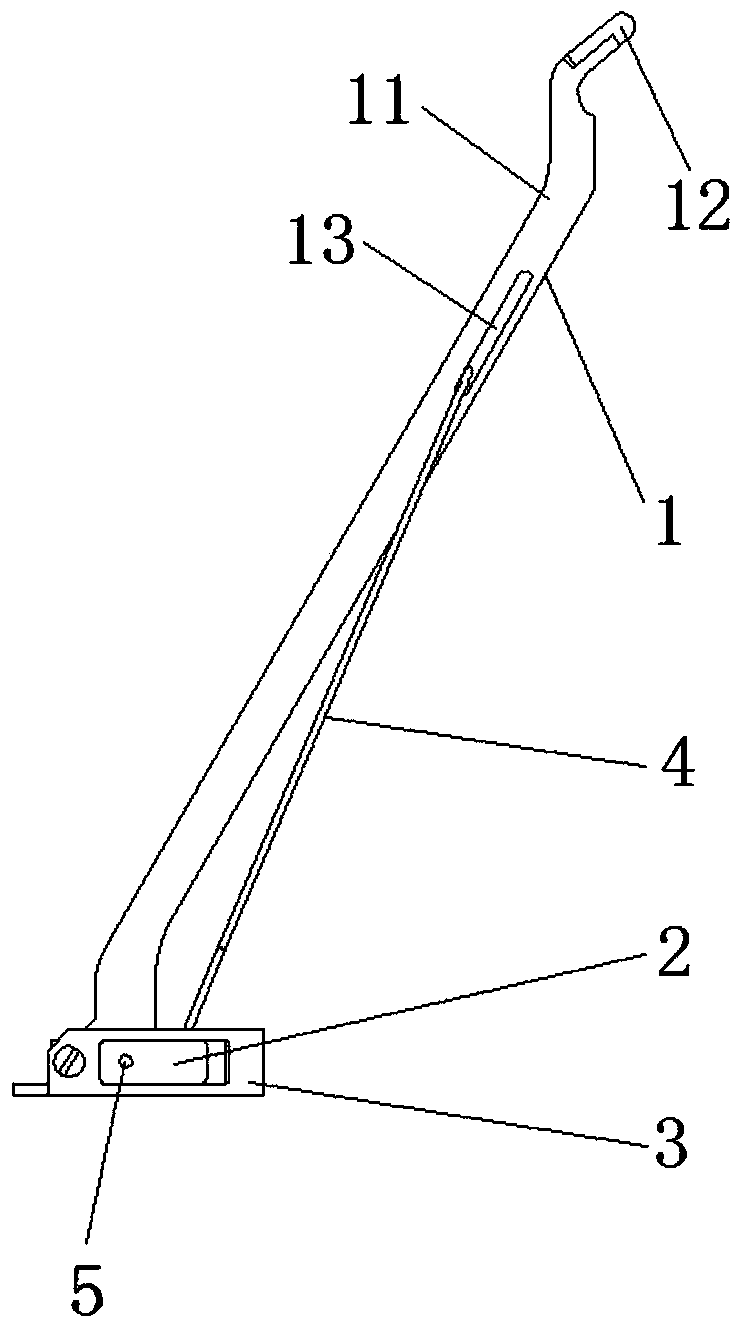

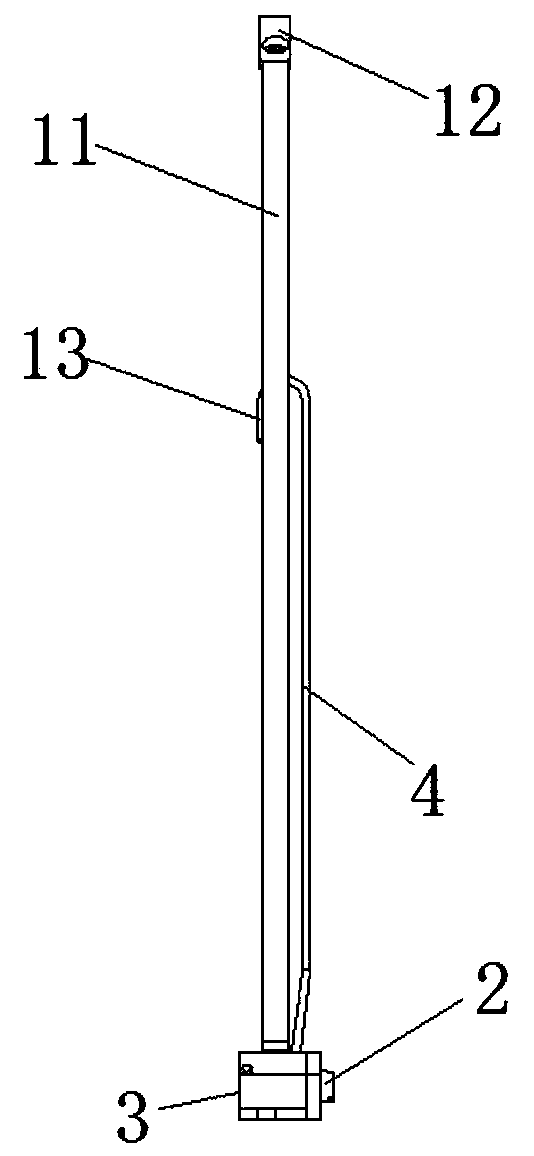

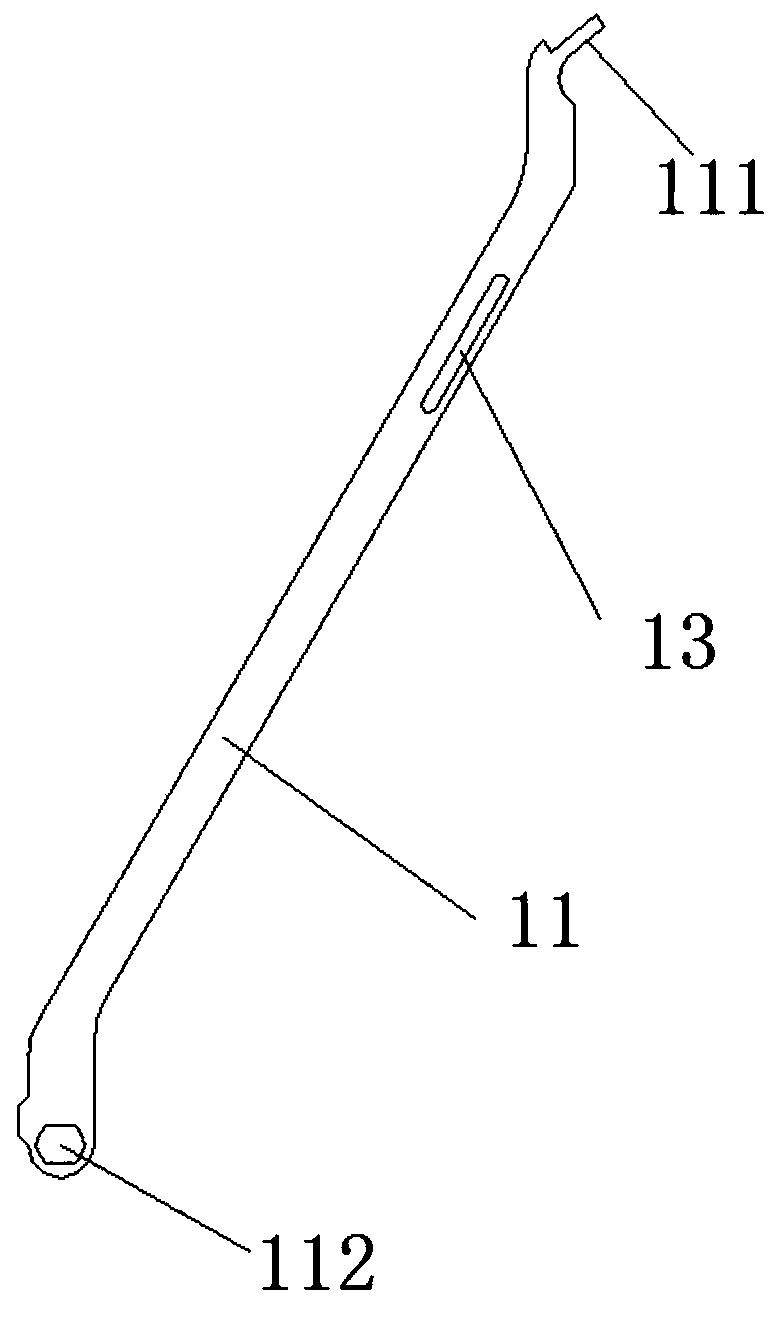

[0025] see figure 1 , is a schematic diagram of the main structure of a new type of caliper probe for pipeline detectors provided by this application. see figure 2 , is a schematic diagram of the side structure of a new type of caliper probe for pipeline detectors provided by this application. see image 3 , is a schematic structural diagram of the probe assembly provided in this application.

[0026] A new type of caliper probe for pipeline detectors, including a probe assembly 1, a caliper sensor 2, a base assembly 3, a torsion spring structure 4, a rotating shaft 5 and a magnet 6; the probe assembly 1 includes a probe arm 11 and a wear-resistant The sheet 12, the probe arm 11 is used to profile the diameter change of the inner wall of the pipeline, and change the linear change value of the pipeline into an angular change value. The probe arm 11 is a structure with a narrow top and a wide bottom in practical applications, which is conducive to ensuring its strength. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com