Automatic visual inspection system of PCB and working method of automatic visual inspection system

A PCB circuit board, visual inspection technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as size error, component shape error, low efficiency, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

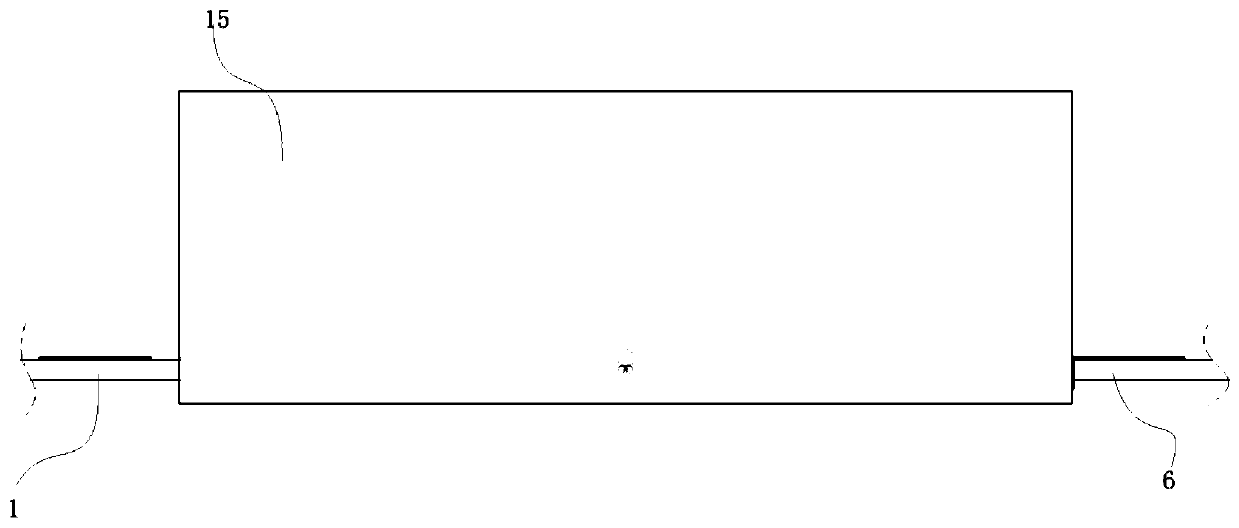

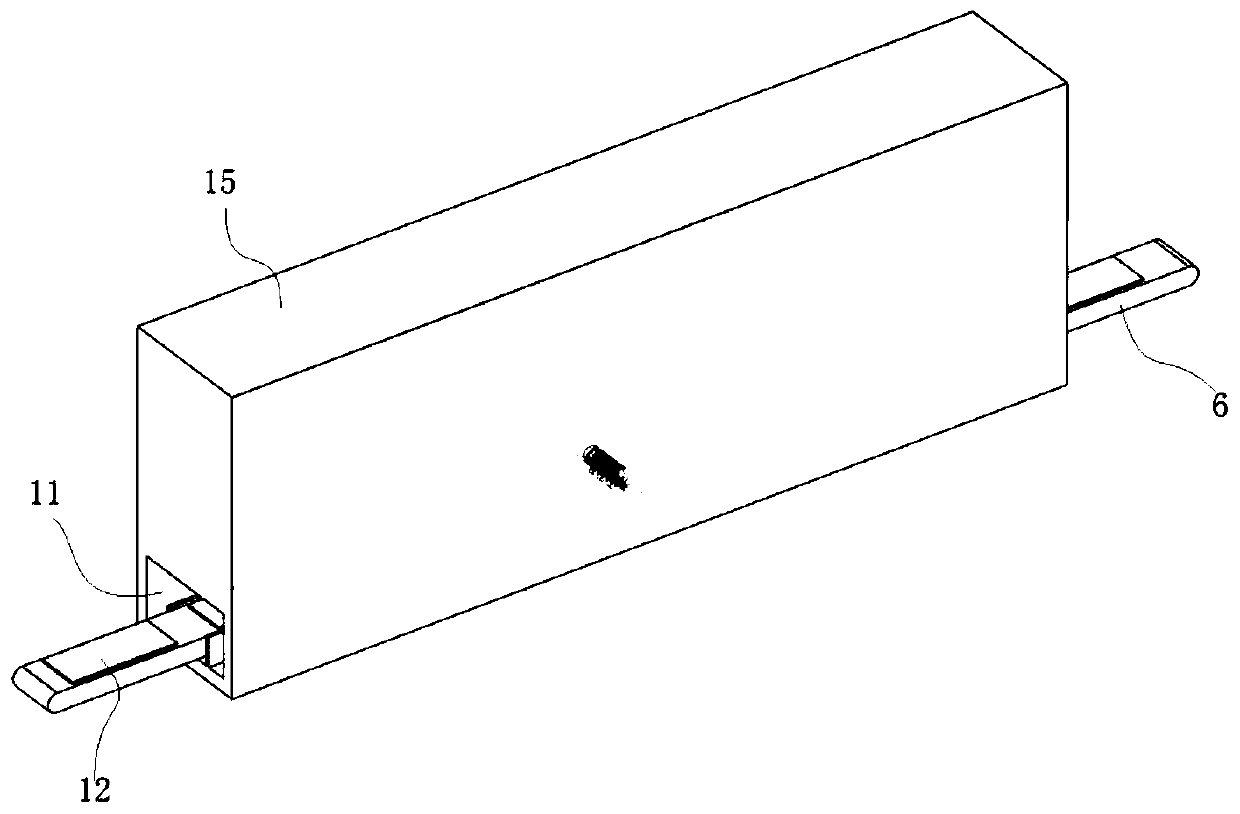

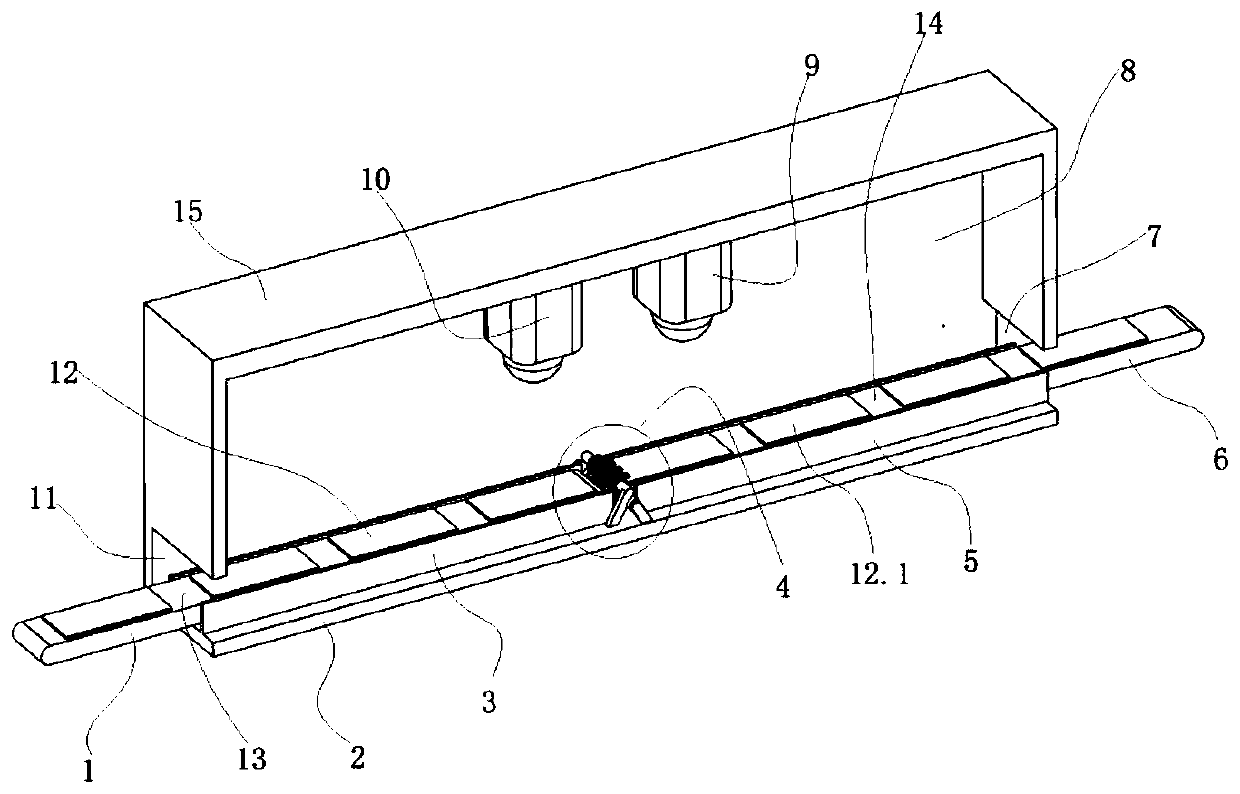

[0042] as attached Figures 1 to 12 The automatic visual detection system of the PCB circuit board shown includes a dark box 15, and the inside of the dark box 15 is a visual inspection room 8, and an industrial camera is arranged inside the visual inspection room 8;

[0043] The lower side of the front and rear walls of the dark box 15 are respectively provided with a front transfer port 11 and a rear transfer port 7 that pass through the inside of the visual inspection chamber 8; The conveying surface 13 is flat with the rear conveying surface 14 on the rear conveyor belt unit 6; both the front conveying surface 13 and the rear conveying surface 14 can horizontally convey the PCB board along the length direction;

[0044] The outgoing end of the front conveyor belt unit 1 passes through the front transmission port 11 along the front-rear direction and extends horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com