Membrane material-based micro-fluidic chip

A microfluidic chip and membrane material technology, applied in the direction of analysis materials, material inspection products, fluid controllers, etc., can solve the problem that there is no way to integrate chip precision level structure, lateral chromatography technology has no control means, and lateral layers are limited Analysis of technical precision and accuracy and other issues, to achieve the effect of simple design, fast detection, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

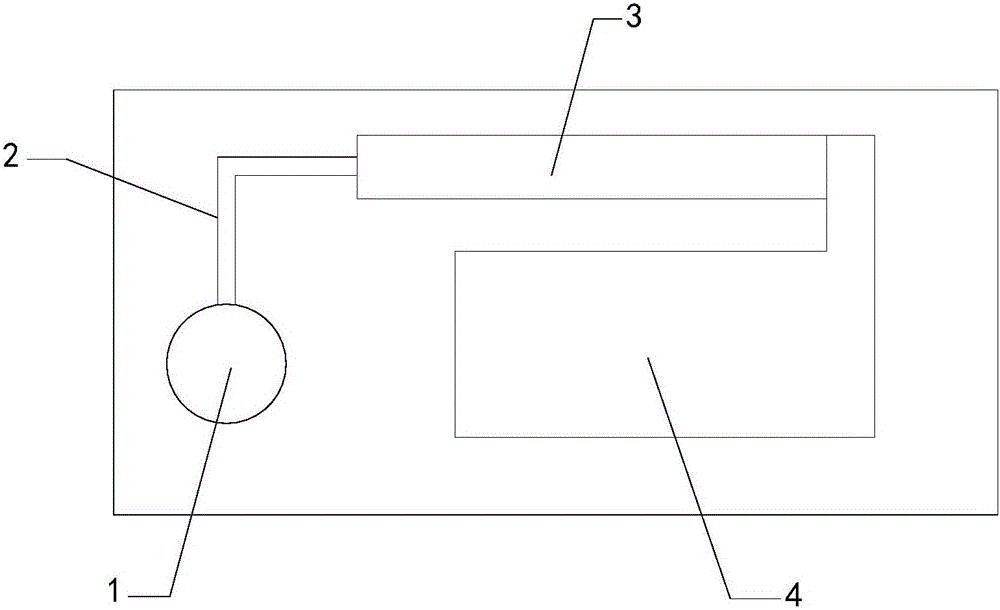

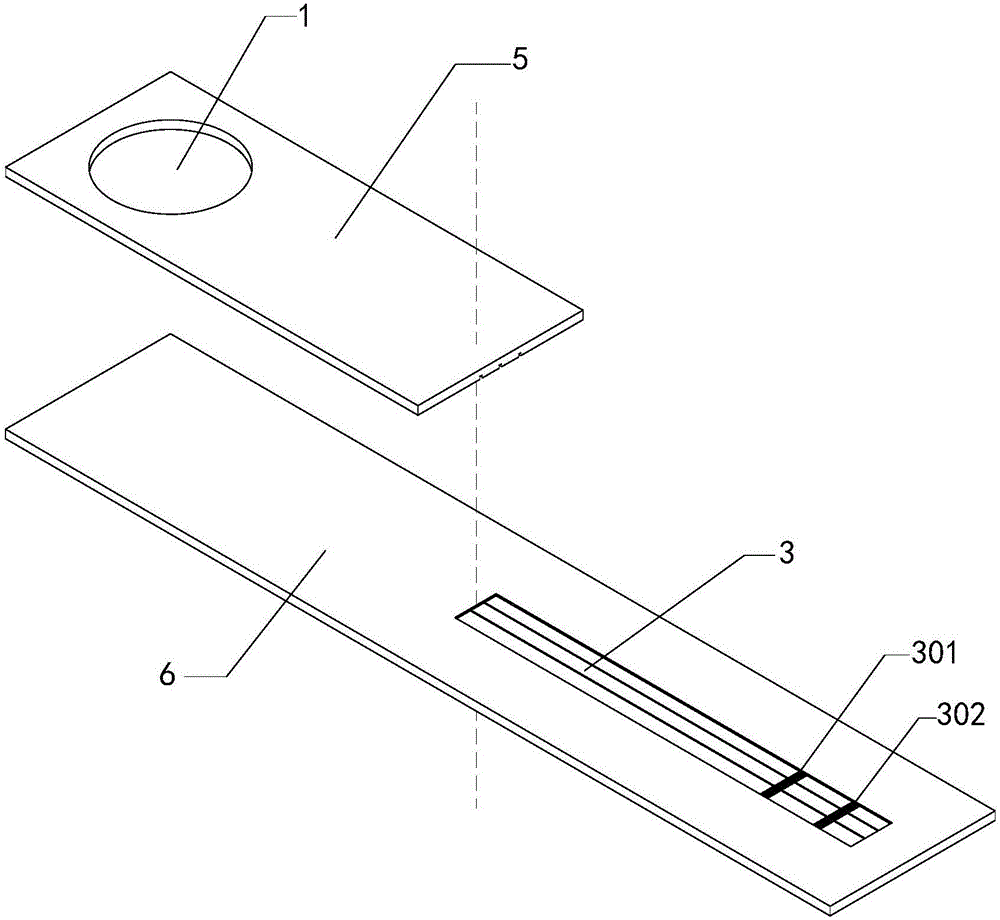

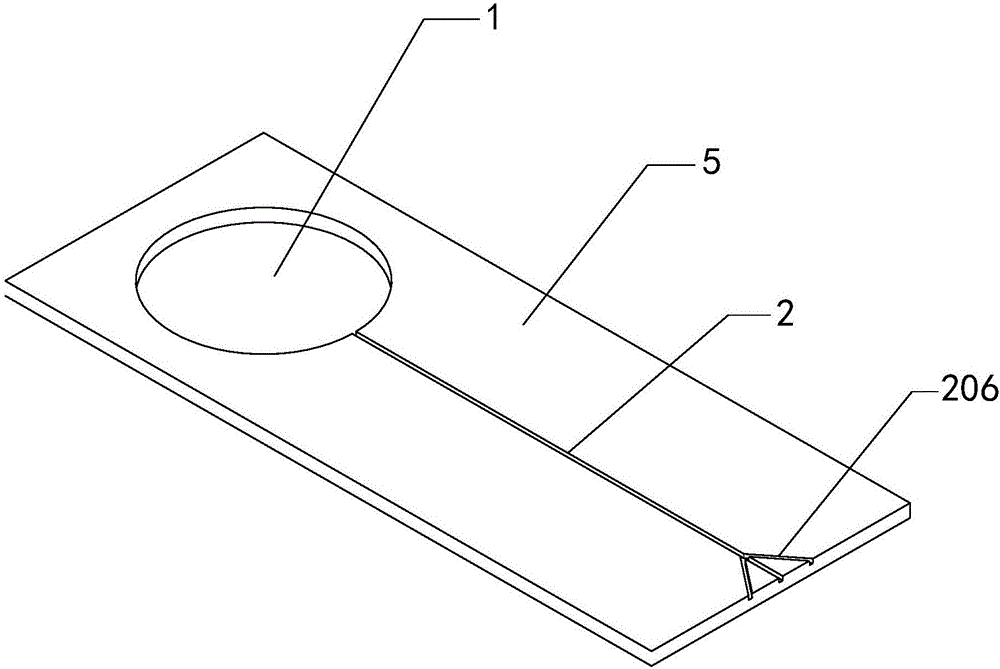

[0035] see figure 1 , a microfluidic chip based on a membrane material in a preferred embodiment of the present invention includes a sample port 1, a fluid channel 2, a detection area 3 and a liquid collection area 4 that are connected to each other in sequence, wherein the fluid channel 2 is used to The sample added by the sample injection port is transported to the detection area under capillary action. The detection membrane for lateral flow detection of the sample is provided in the detection area 3, and the collection device for absorbing excess samples is provided in the liquid collection area 4. One end of the membrane is connected to the fluid channel and the other end is connected to the collection device. It should be noted that the main difference between the microfluidic chip based on the membrane material of the present invention and the prior art is that the microfluidic technology is used to make the sample liquid flow autonomously under capillary action, and no...

Embodiment 2

[0048] The present invention provides a method for preparing the aforementioned microfluidic chip based on membrane materials, comprising the following steps:

[0049] S1. Chip preparation: process the upper chip and the lower chip into such Figure 1 to Figure 10 the structure shown;

[0050] S2. Detection membrane preparation: pour the membrane material raw material into the detection area, remove excess volatile components after shaping, and form a detection membrane;

[0051] S3. Flow channel processing: Design the part of the flow channel that needs to be burned and removed on the software, use laser to process the flow channel on the detection film according to the design, and form multiple detection diaphragms;

[0052] S4. Probe preparation: Coupling the antibody required in the lateral flow detection process to the fluorescent protein;

[0053] S5. Preparation of immune reagents: respectively coat the required antibodies or antigens on the detection line and control...

Embodiment 3

[0061] The present invention provides a method for using the membrane material-based microfluidic chip described in Embodiment 1. In this example, the myoglobin monoclonal antibody prepared by conventional monoclonal antibody technology was used to immobilize myoglobin antibody and rabbit IgG in the rear region of the detection membrane to form a detection line and a control line. Erythroprotein monoclonal antibody and goat anti-rabbit IgG are coupled with fluorescent microspheres (diameter 200nm) as a probe solution, and then the myoglobin antigen in the sample is detected by the double-antibody sandwich method, and the myoglobin in the liquid sample to be tested is detected protein content.

[0062] Specific steps are as follows:

[0063] S1. Probe preparation

[0064] 1) Take 500 μl of fluorescent latex particle solution (containing carboxyl groups) with an emission wavelength of 550nm to 700nm, wash with pH6.0 MES buffer and centrifuge three times, then dilute the precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com