Batching and stock layout iterative optimization method based on blanking utilization rate prediction

It is an iterative optimization and utilization technology, which is applied in forecasting, data processing applications, and calculation models. Calculate the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

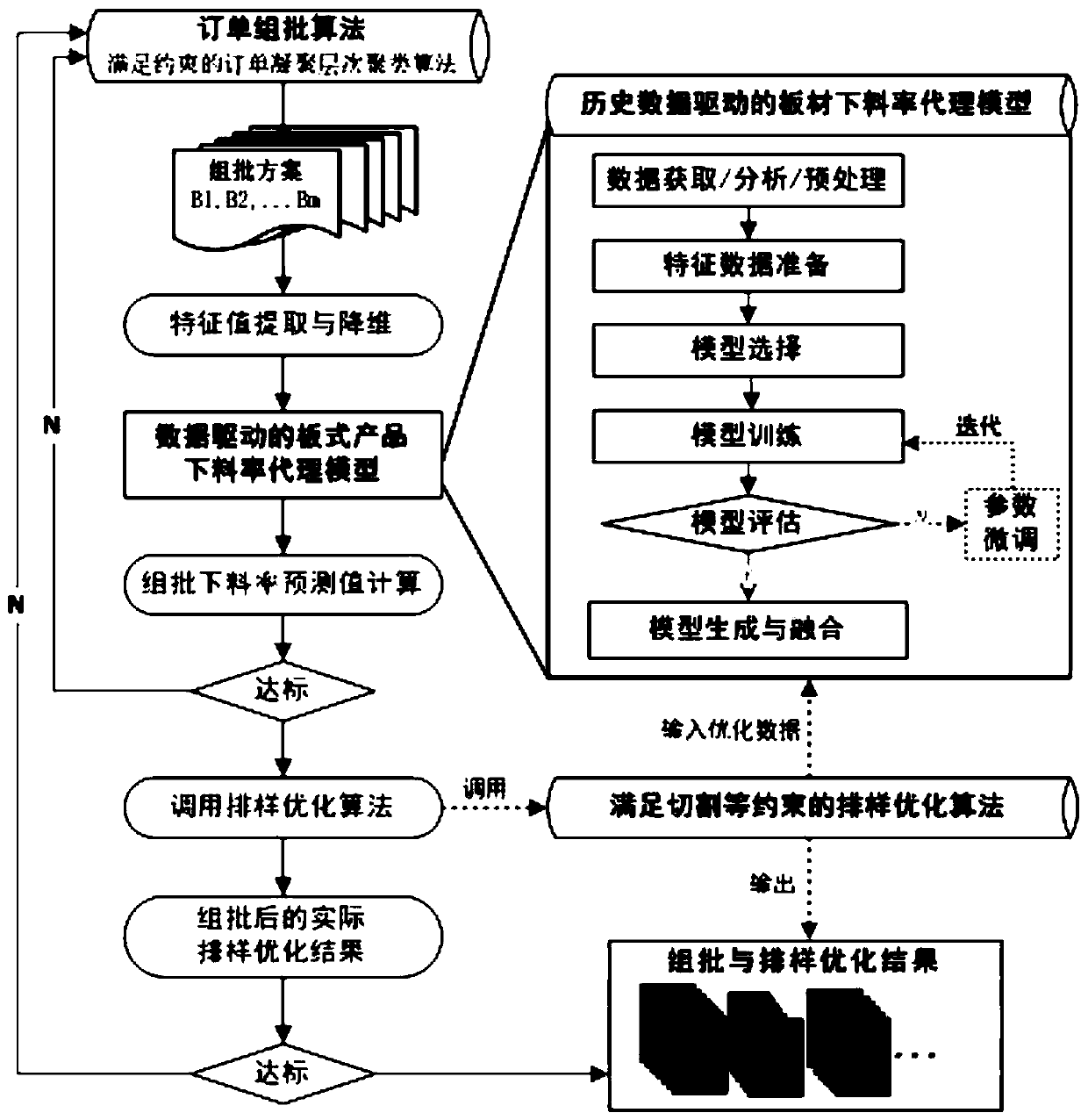

[0045] refer to Figure 1 to Figure 4 As shown, an iterative optimization method for grouping and layout based on the prediction of blanking utilization rate in this embodiment includes the following steps:

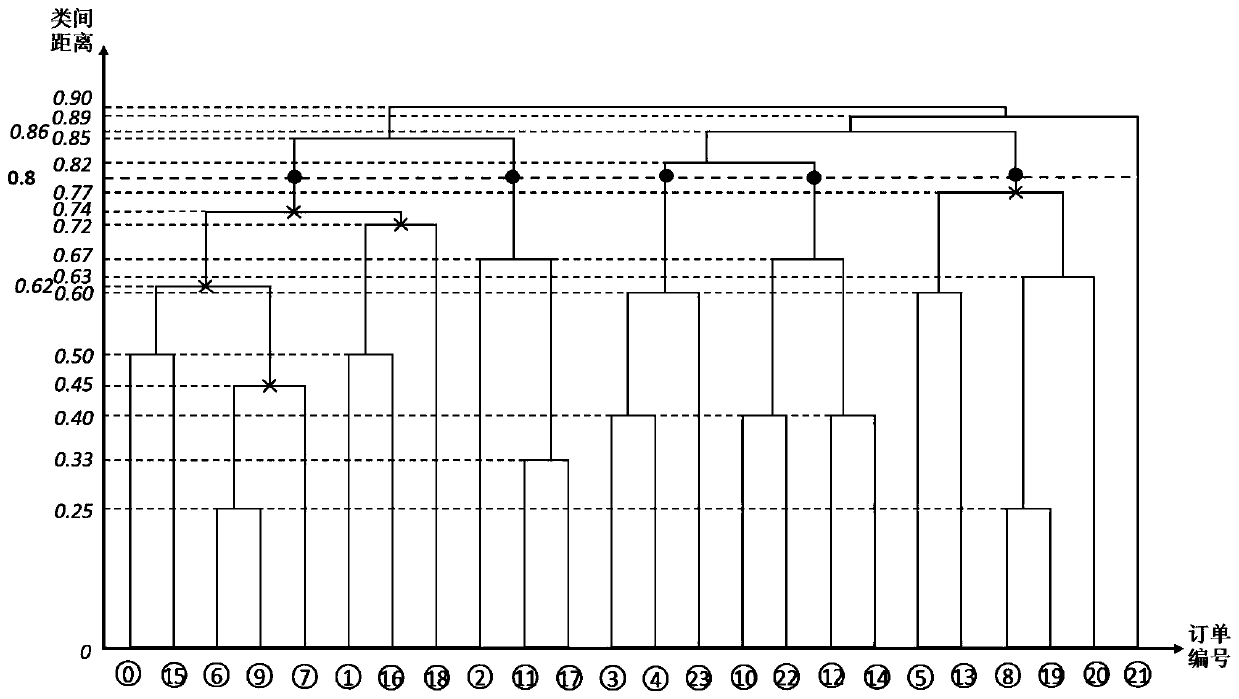

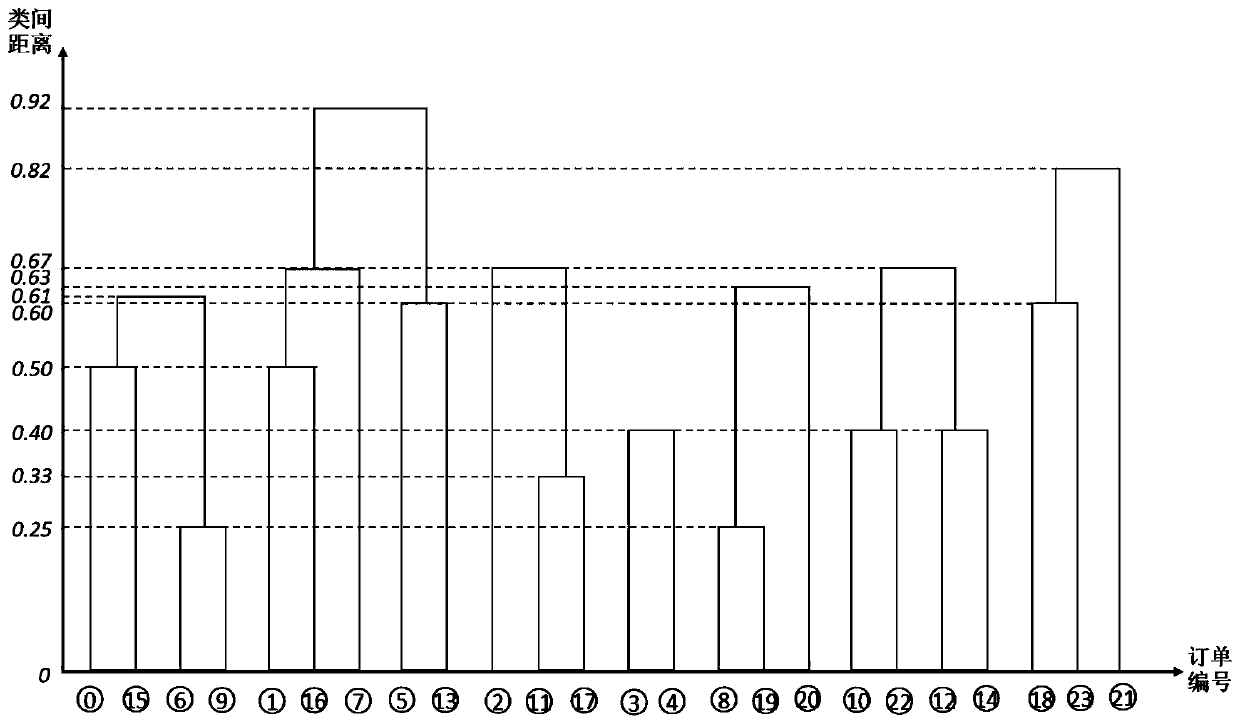

[0046] Order batching: optimize the order batching according to the order agglomerative hierarchical clustering algorithm that meets the delivery time deviation and production constraints, and obtain multiple feasible batching schemes;

[0047] Feature extraction and dimensionality reduction: use the plates of the same material in each batch in each batch scheme as the minimum prediction sample;

[0048] Input the forecast model to get the forecast result: input all the minimum forecast samples in each batch plan into the blanking utilization forecast model to predict the layout results, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com