Non-uniform sample equalization method and system for product assembly process

An assembly process and non-uniform technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as non-uniformity, strong data correlation, and difficult homogenization of samples, so as to achieve scientific results and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

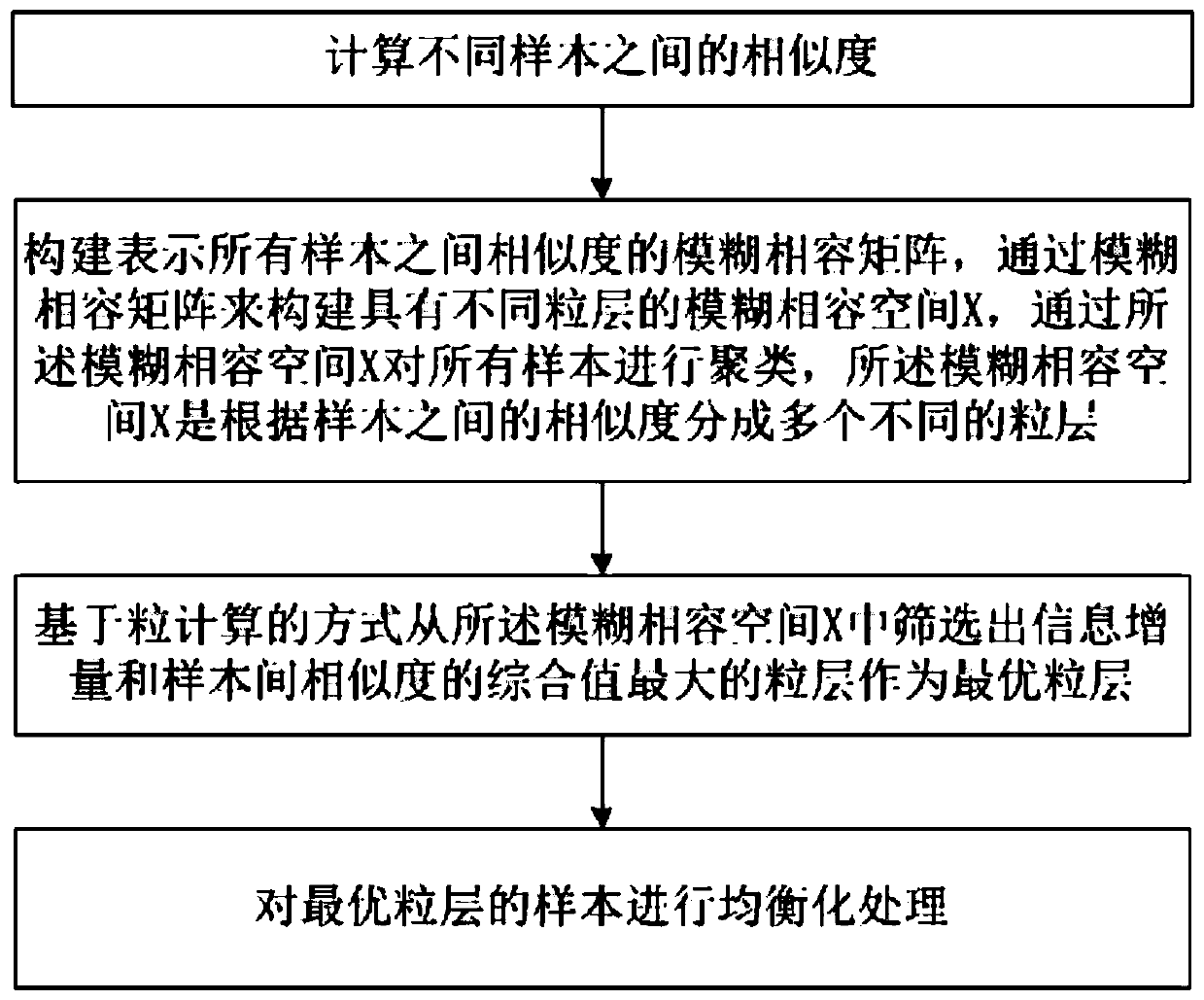

[0021] The non-uniform sample equalization method oriented to the product assembly process in this embodiment takes the topology of the assembly process of the product as a sample, and the topology of the assembly process of the same product of different styles is a different sample, such as figure 1 shown, including the following steps:

[0022] Step A, calculating the similarity between different samples;

[0023] Step B, construct a fuzzy compatibility matrix S representing the similarity between all samples, construct a fuzzy compatibility space X with different granular layers through the fuzzy compatibility matrix S, and aggregate all samples through the fuzzy compatibility space X class, the fuzzy compatible space X is divided into multiple different granular layers according to the similarity between samples;

[0024] Step C, selecting the granular layer with the largest integrated value of information increment and similarity between samples from the fuzzy compatible...

Embodiment 2

[0065] The non-uniform sample equalization system oriented to the product assembly process in this embodiment takes the topology of the assembly process of the product as a sample, and the topology of the assembly process of the same product of different styles is a different sample, including:

[0066] A similarity generation module is used to calculate the similarity between different samples;

[0067] The fuzzy compatibility space construction module is used to construct a fuzzy compatibility matrix S representing the similarity between all samples, and construct a fuzzy compatibility space X with different granular layers through the fuzzy compatibility matrix S, and through the fuzzy compatibility space X clusters all samples, and the fuzzy compatible space X is divided into multiple different granular layers according to the similarity between samples;

[0068] The optimal granular layer generation module is used to select the granular layer with the largest comprehensiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com