Anticorrosion spraying device for chimney inner wall and inner wall support hanger

A technology of anti-corrosion spraying and supporting hangers, which is applied in spraying devices, spray booths, cleaning methods and utensils, etc., can solve the problems of low efficiency and high safety hazards, and achieve the effect of expanding the cleaning range, reducing safety hazards and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

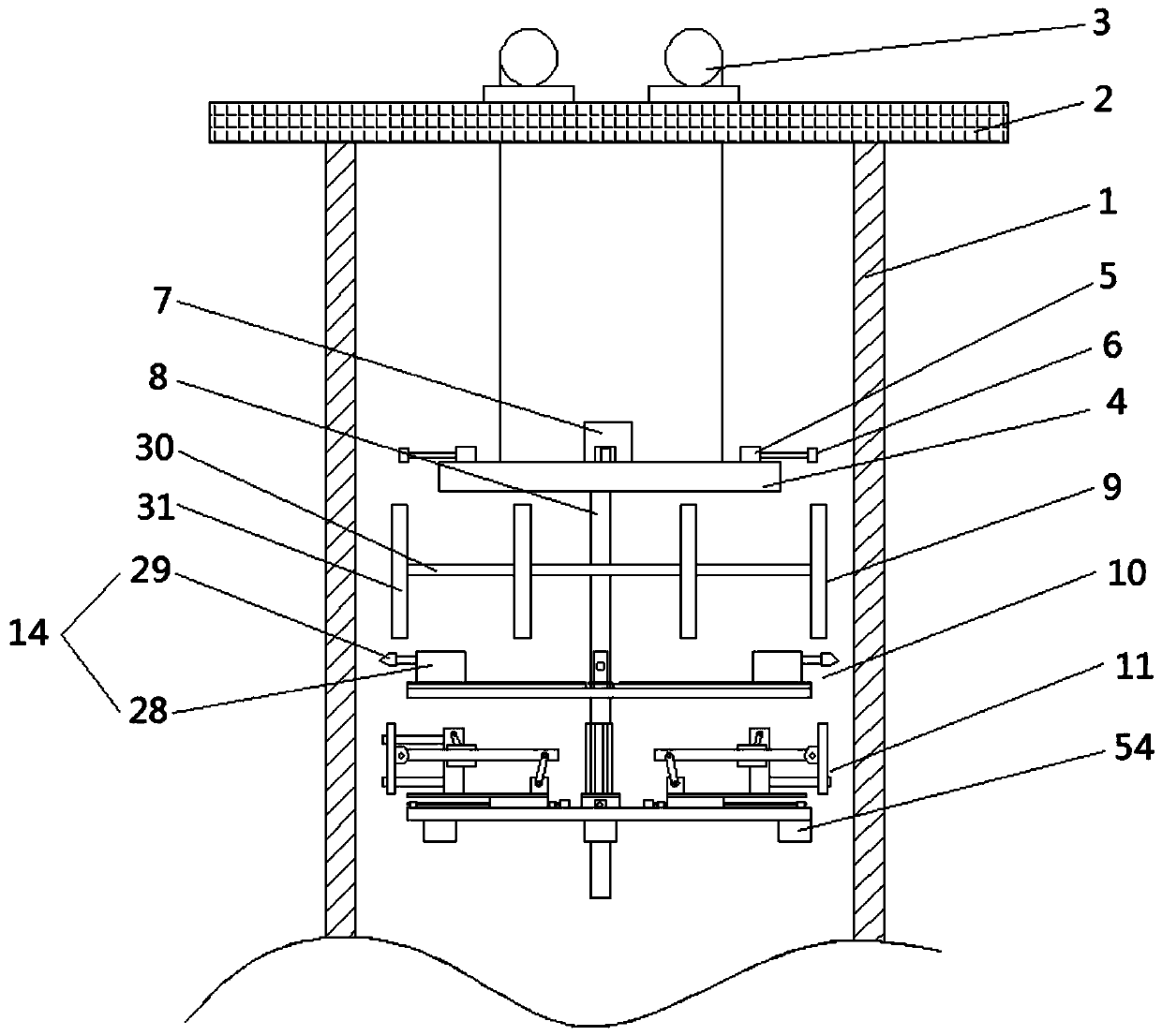

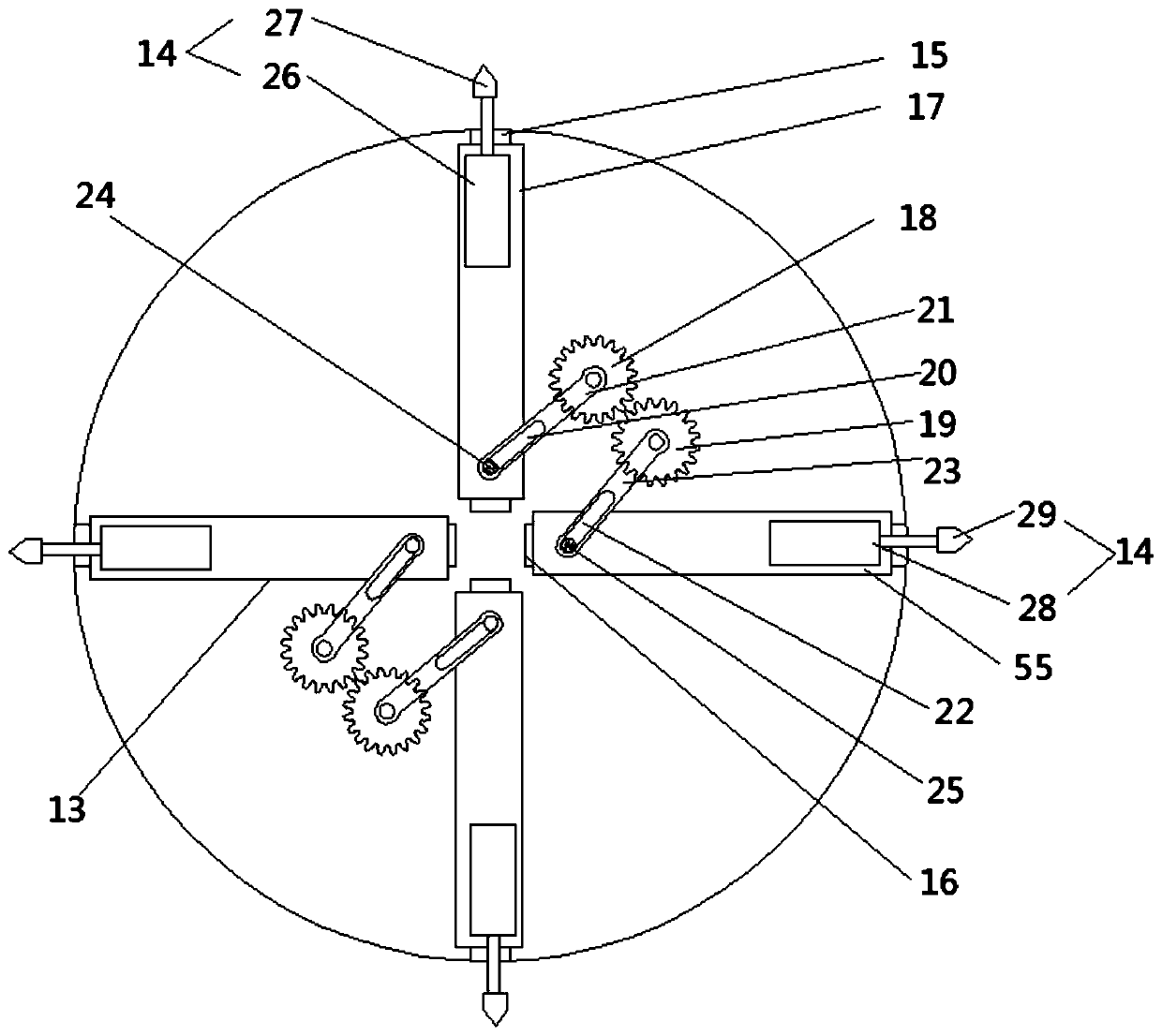

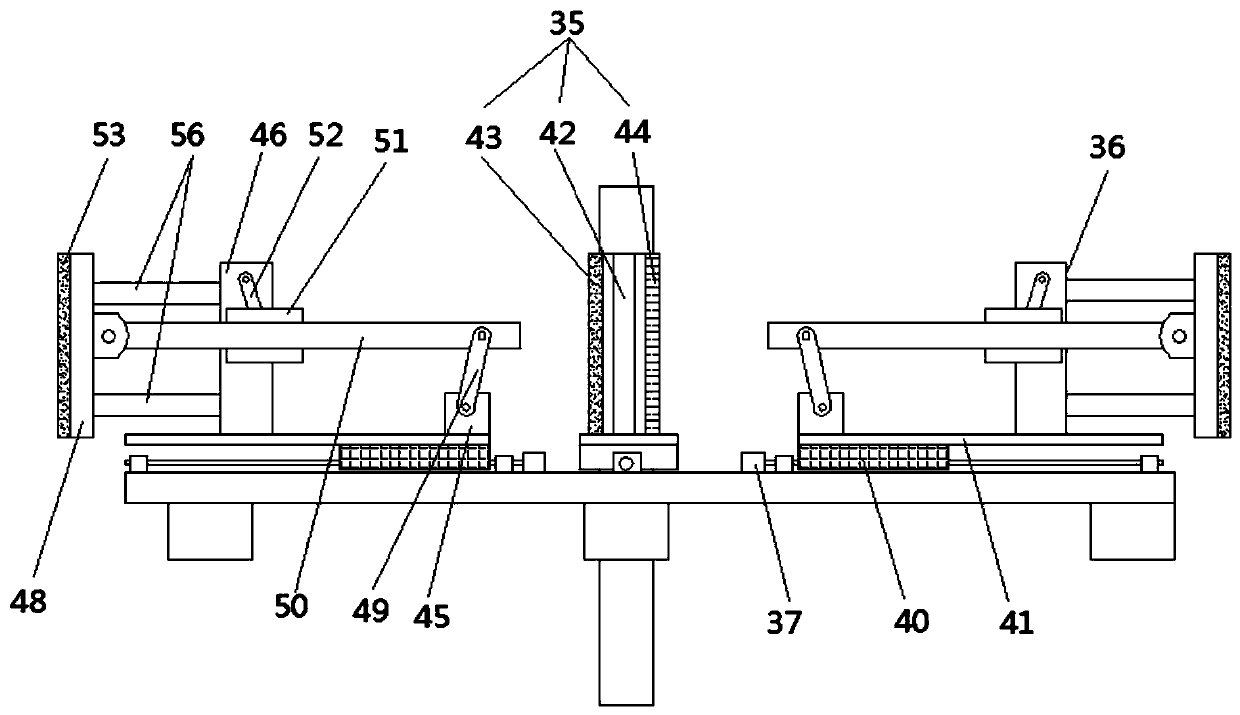

[0026] An anticorrosive spraying device for the inner wall and the inner wall supports and hangers of the chimney, comprising a fixed plate 2 installed on the top of the chimney 1, a hoist 3 installed on the top of the fixed plate 2 and wound with a steel wire rope, and installed on the steel wire rope and located in the chimney 1. Support plate 4, a plurality of electric push rods 5 installed on the support plate 4 and evenly distributed around the center axis of the support plate 4, installed on the electric push rod 5, a vacuum suction cup 6 used for limiting the position, installed on the support plate 4 The first motor 7 at the central position is rotated by a rolling bearing on the main shaft 8, which is mounted on the support plate 4 and coaxially with the support plate 4, is mounted on the main shaft 8 and is located below the support plate 4 from the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com