Straight cylinder type high-pressure cleaning device and high-pressure cleaning system

A high-pressure cleaning, straight-tube technology, applied in mechanical equipment, variable displacement pump components, cleaning methods and utensils, etc., can solve the problems of poor flexibility, unfavorable liberation of the operator's hands, etc., to achieve easy storage, improve cleaning effect, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

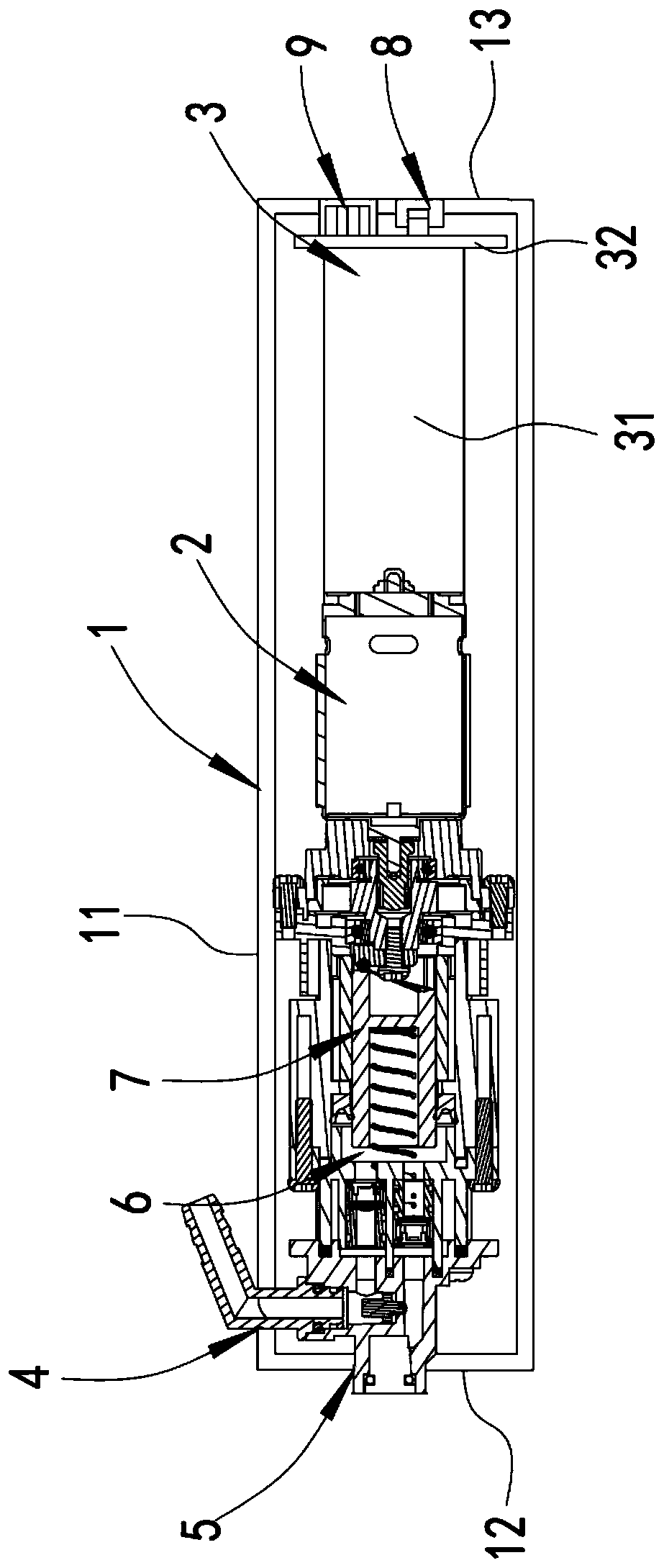

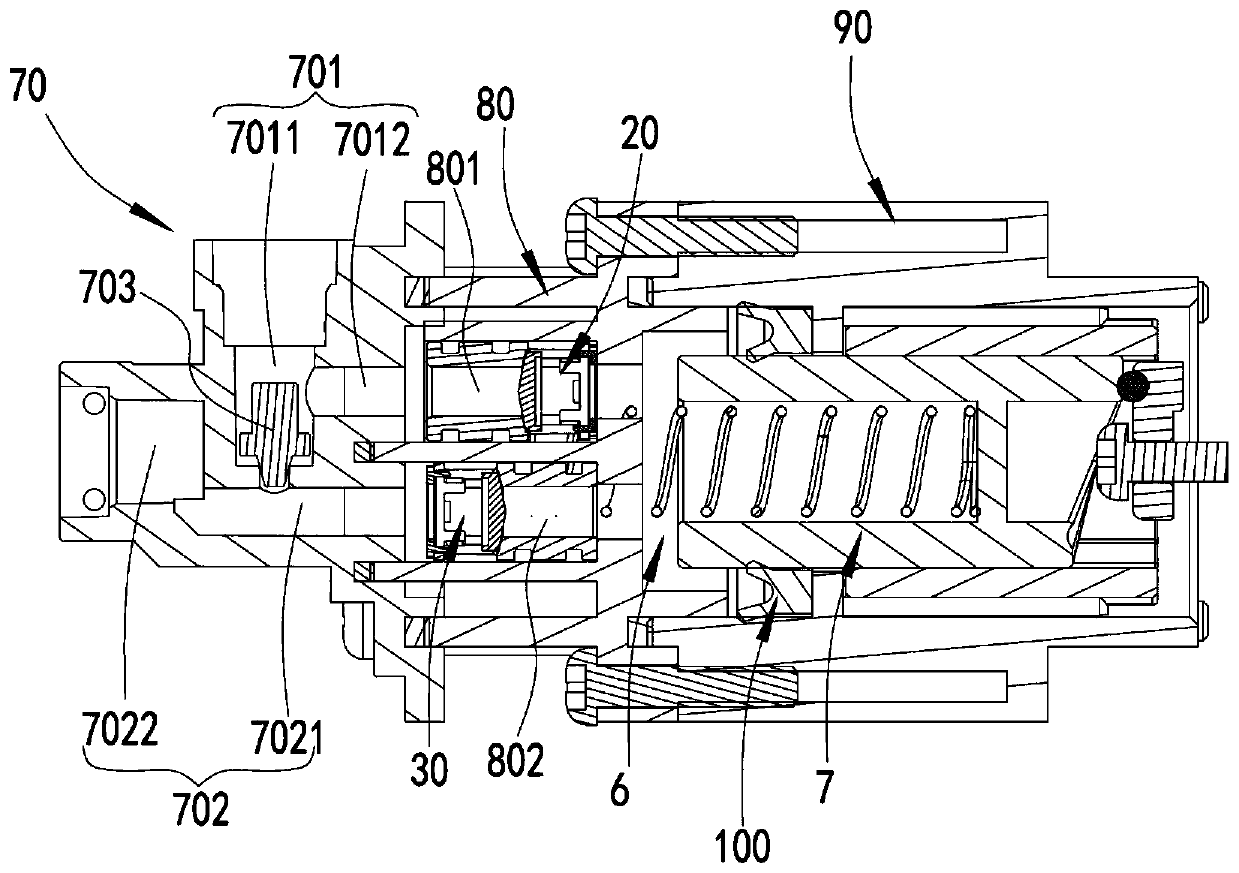

[0059] as attached figure 1 , attached figure 2 As shown, the fluid inlet 4 and the fluid outlet 5 are connected to the fluid entry and exit control mechanism located in the casing 1, the fluid entry and exit control mechanism is preferably close to the front end of the casing 1, and the fluid entry and exit control mechanism is located in the piston. 7 When moving from the far end (the end where the entire device points to the front when the user uses it) to the proximal end (the end where the entire device points to the rear when the user uses it) (during suction), only the external fluid is allowed to be sucked in by the fluid inlet 4 In the pressurized chamber 6, the fluid in the pressurized chamber 6 cannot be discharged through the fluid outlet 5; and when the piston 7 moves from the proximal end to the distal end (when squeezed), the external fluid is not allowed to pass through the fluid inlet 4 is sucked into the pressurized chamber 6, and only the fluid in the pre...

Embodiment 2

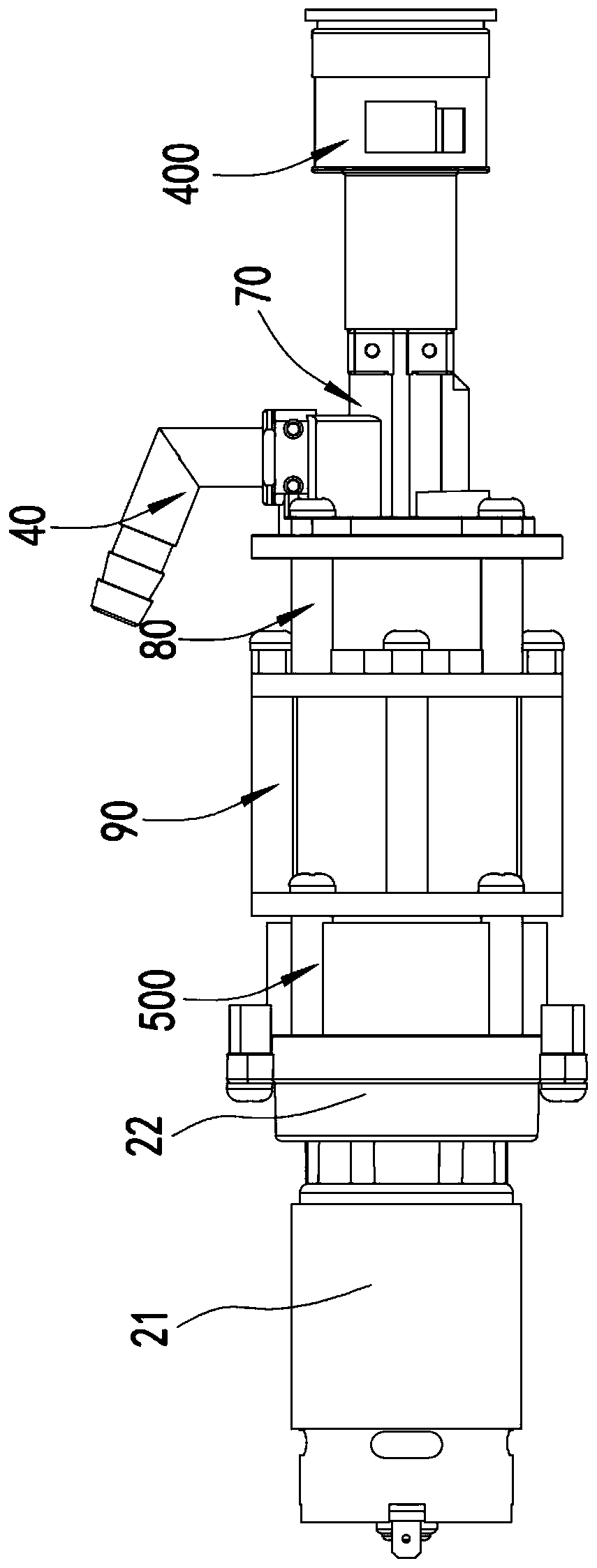

[0071] The difference between this embodiment and the above-mentioned embodiment 1 is that: Figure 5 As shown, the fluid inlet 4 is arranged at the proximal end of the housing 1, preferably at the end face of the proximal end, that is, the fluid inlet 4 includes at least one hole on the end panel 13 at the proximal end of the housing. , since there is a relatively large distance between the fluid inlet 4 and the far-end fluid entry and exit control mechanism, a fluid channel 300 is also provided between the fluid inlet 4 and the inlet of the fluid entry and exit control mechanism, and the fluid The channel 300 is preferably disposed inside the housing 1 , of course, it can also be disposed outside the housing 1 in other embodiments.

[0072] At this time, the fluid inlet 4 can also vertically extend outward for a certain distance from the proximal end panel 13 of the housing 1 , so as to facilitate detachable connection with the pipe joint 40 or an external pipe. Of course, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com