Automatic threading machining device for large-opening-diameter steel pipe joint

A steel pipe joint and large-diameter technology, which is applied in the field of automatic threading processing equipment for large-diameter steel pipe joints, can solve the problems of high frequency of manual parts replacement, reduced pass rate of large-diameter steel pipe joint products, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

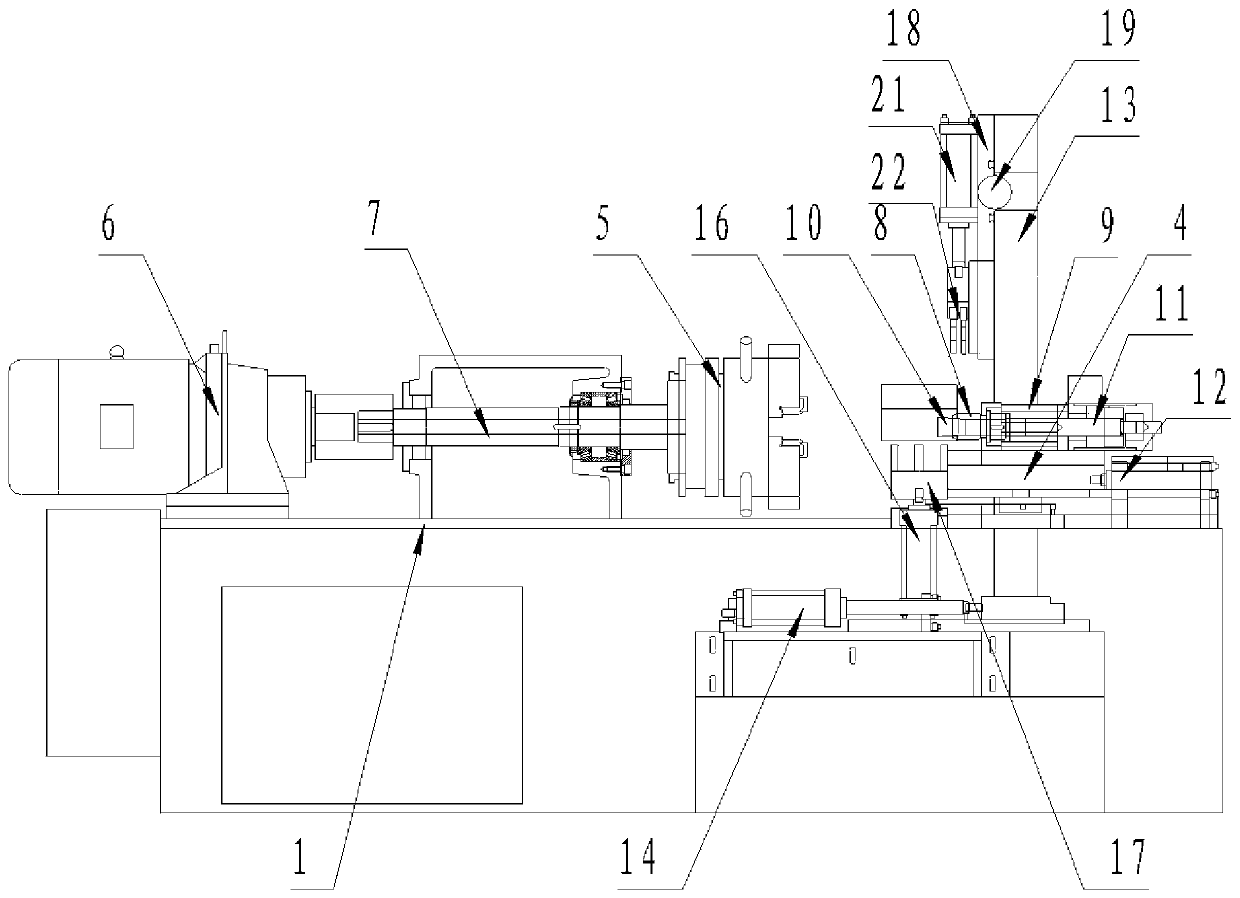

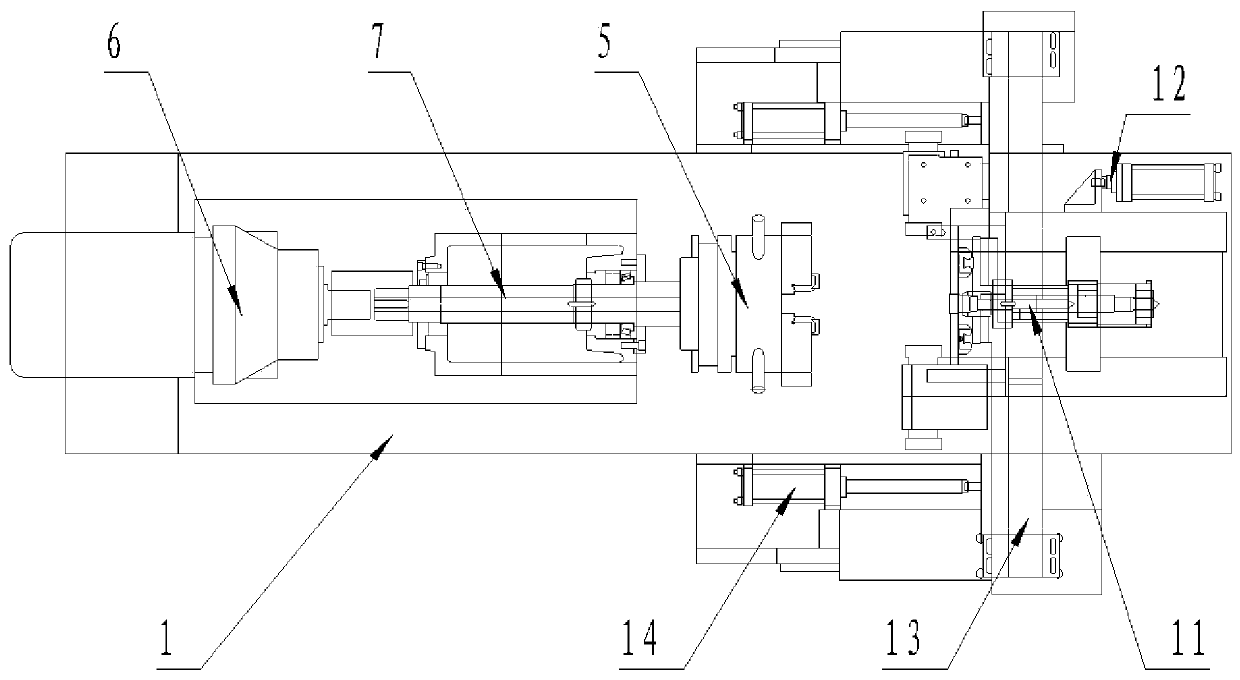

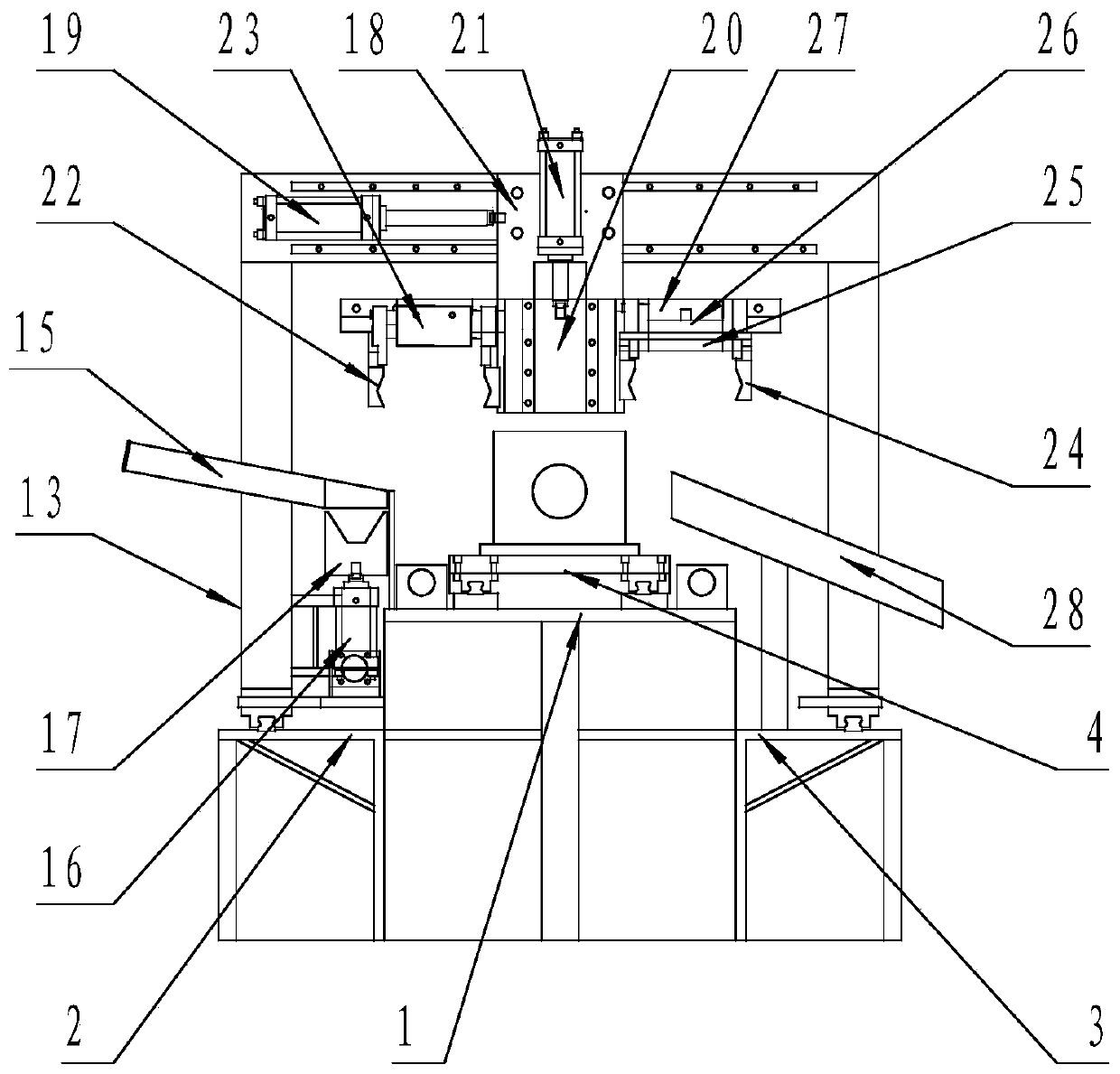

[0024] like figure 1 , figure 2 , image 3 As shown, a large-diameter steel pipe joint automatic threading processing equipment includes a main strip frame, a main strip workbench 1 installed on the main strip frame, and a front panel set on the front side of the main strip frame. The front sub-strip workbench 2 on the sub-strip frame and the front sub-strip frame (the observer faces the invention, the left side of the observer's left side is the main strip workbench, and the observer's right side is the main strip the right side of the main bar-shaped workbench; the side close to the main bar-shaped workbench is the front side of the main bar-shaped workbench, the side away from the main bar-shaped workbench is the rear side of the main bar-shaped workbench); The rear auxiliary strip-shaped rack arranged on the side and the rear auxiliary strip-shaped workbench 3 on the rear auxiliary strip-shaped rack, the main strip-shaped rack and the auxiliary strip-shaped racks respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com