Grinding wheel for gallium arsenide crystal thinning, preparation method and application

A gallium arsenide and grinding wheel technology, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high grinding resistance, high processing difficulty, reduced production efficiency, etc. The effect of reducing the surface damage layer and improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

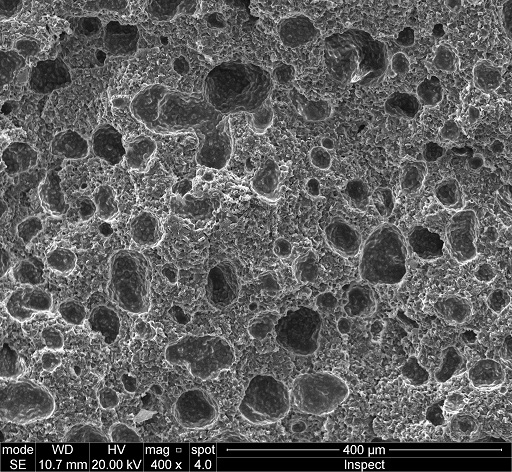

Image

Examples

Embodiment 1

[0026] A grinding wheel for gallium arsenide crystal thinning, its components include: 10% diamond abrasive, 42% polyimide resin powder, 10% azo foaming agent, 10% calcium fluoride, disulfide Molybdenum 10%, zinc oxide 10%, white corundum 8%.

[0027] The azo foaming agent has been processed. The treatment method is: dissolve the azo foaming agent in dimethylformamide solvent, then put it in a vacuum drying oven at 80°C for 2 hours, pulverize it with a pulverizer for 2 hours, and pass through liquid nitrogen. Cooling treatment, milling with a planetary ball mill for 4 hours, and finally sieving with 300# and 400# standard sieves to obtain a foaming agent with a particle size distribution of 50-60 μm after treatment.

[0028] The preparation method of the grinding wheel for gallium arsenide crystal thinning comprises the following steps:

[0029] (1) Put the treated foaming agent and polyimide resin powder into a planetary mixer for ball mixing for 1 hour, and then pass throug...

Embodiment 2

[0034] A grinding wheel for gallium arsenide crystal thinning, its components include: 25% diamond abrasive, 25% polyimide resin powder, 8% azo foaming agent, 20% calcium fluoride, disulfide Molybdenum 4%, zinc oxide 6%, white corundum 12%.

[0035] The azo-type foaming agent is processed, and the treatment method is: dissolve the azo-type foaming agent in dimethylformamide solvent, then put it into a vacuum drying oven at 80°C for 2 hours, pulverize it with a pulverizer for 2 hours, and Cooling treatment with liquid nitrogen, milling with a planetary ball mill for 4 hours, and finally sieving with 300# and 400# standard sieves to obtain a foaming agent with a particle size distribution of 50-60 μm after treatment.

[0036] The preparation method of the grinding wheel for gallium arsenide crystal thinning comprises the following steps:

[0037] (1) Put the treated foaming agent and polyimide resin powder into a planetary mixer for ball mixing for 1 hour, and then pass through...

Embodiment 3

[0043] A grinding wheel for gallium arsenide crystal thinning, its components include: 35% diamond abrasive, 15% polyimide resin powder, 20% azo foaming agent, 5% calcium fluoride, disulfide Molybdenum 3%, zinc oxide 12%, white corundum 10%.

[0044] The azo-type foaming agent is processed, and the treatment method is: dissolve the azo-type foaming agent in dimethylformamide solvent, then put it into a vacuum drying oven at 80 degrees for 2 hours, pulverize it with a pulverizer for 2 hours, and Cooling treatment with liquid nitrogen, milling with a planetary ball mill for 4 hours, and finally sieving with 300# and 400# standard sieves to obtain a foaming agent with a particle size distribution of 50-60 μm after treatment.

[0045] The preparation method of the grinding wheel for gallium arsenide crystal thinning comprises the following steps:

[0046] (1) Put the processed foaming agent and polyimide resin powder into the planetary mixer for ball mixing for 1 hour, then pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com