Equipment for charged fastening of support bottle from ground

A fastening and equipment technology, applied in the direction of overhead line/cable equipment, wrench, screwdriver, etc., can solve problems such as difficult to judge the looseness of bolts, difficult operation of fastening with force rotation, loose screws of support bottles, etc., to achieve fixed connection and disassembly It is simple and fast, reduces the rate of manual climbing, and is easy to fasten.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

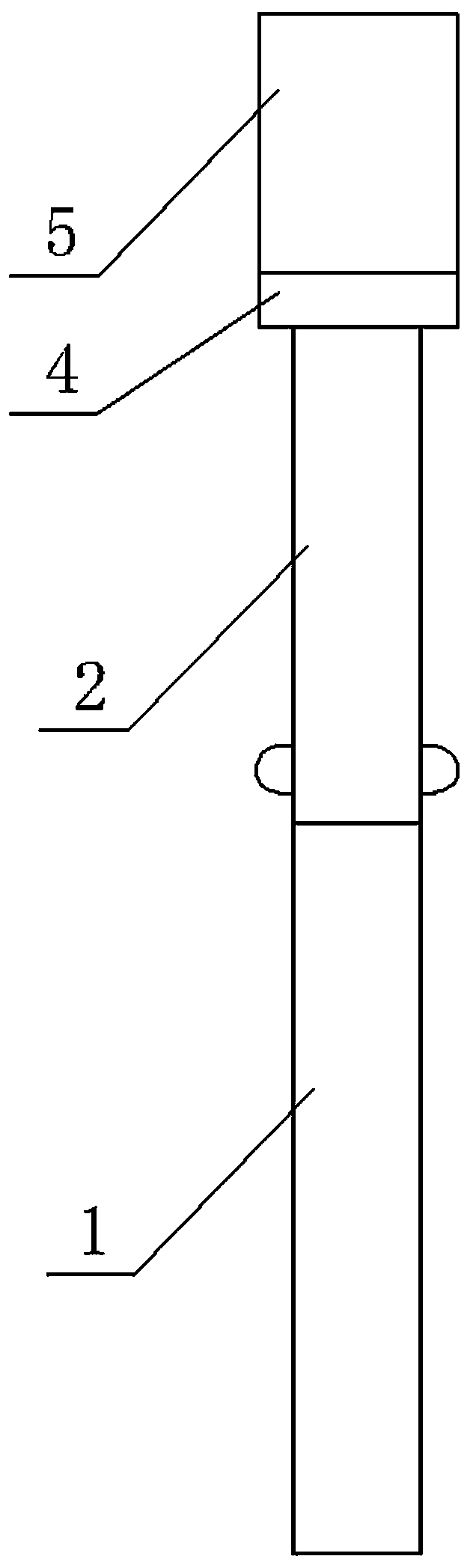

[0046]Such as Figure 1-7 as shown,

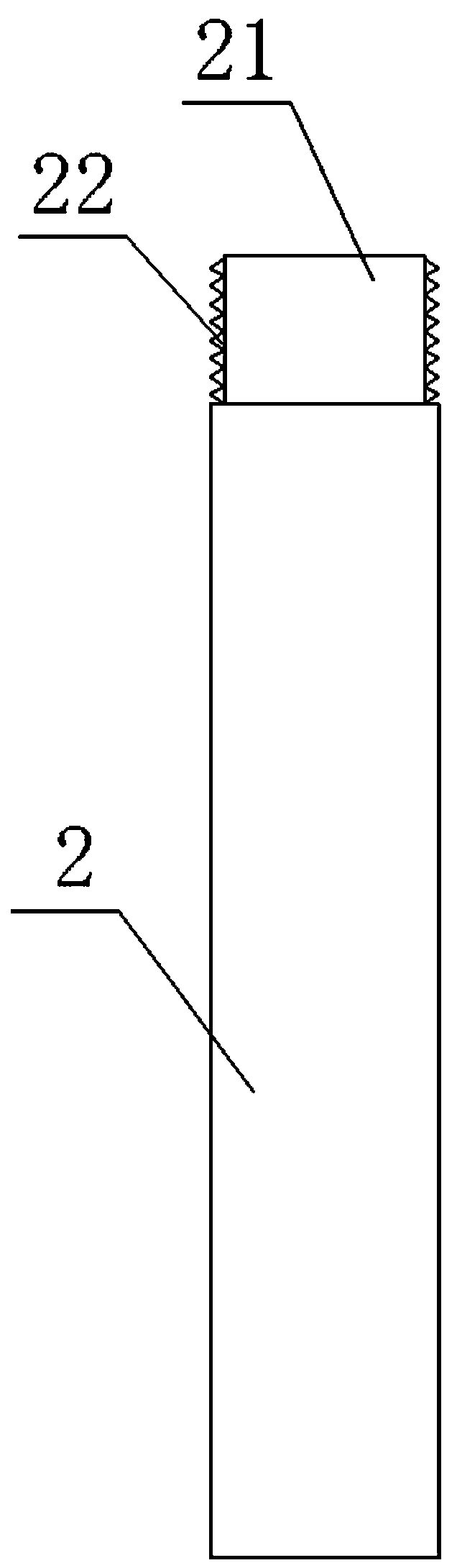

[0047] A device for fastening a bottle with electricity from the ground, comprising a lower insulating rod 1, an upper insulating rod 2 fixedly connected to the upper end of the lower insulating rod 1, and a tightening rod fixedly connected to the upper end of the upper insulating rod 2 through a threaded connection seat 4. Solid screw sleeve 5;

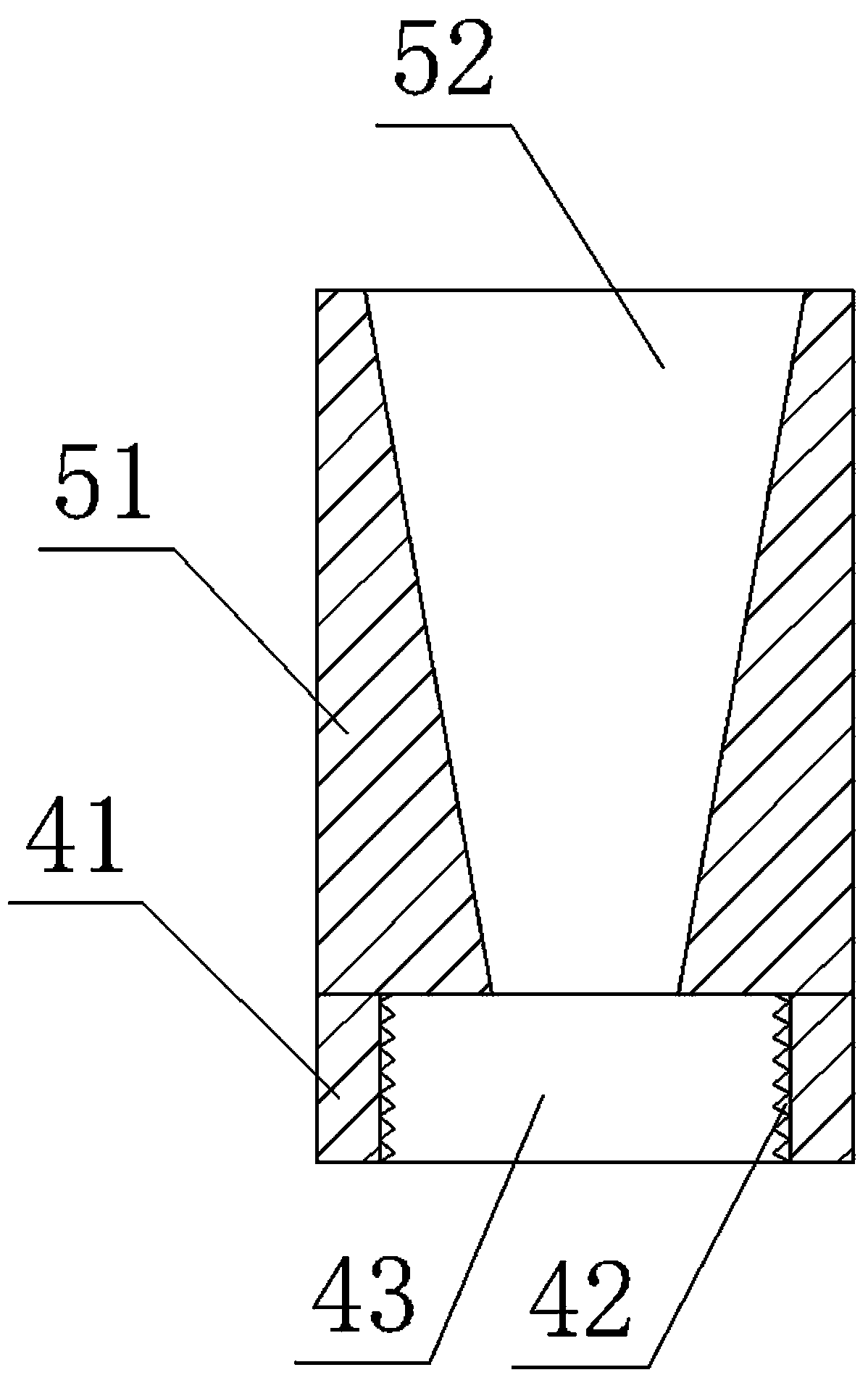

[0048] The fastening nut 5 includes a fastening nut body 51 fixedly connected to the threaded connection seat 4 and a fastening hole 52 formed inside the fastening nut body 51 for fastening the bottle bolt;

[0049] The fastening hole 52 is a regular hexagonal diameter reducing hole that forms an inverted taper from the outer end of the fastening nut body 51 to the inside. Regardless of the size of the bottle support bolt, it can be matched with a certain diameter of the regular hexagonal diameter reducing hole of the fastening hole 52. Matching the hole diameter, both the high and low voltage ...

Embodiment 2

[0062] Such as Figure 2-8 As shown, on the basis of the first embodiment, further optimization, the lower outer part of the lower insulation rod 1 is fixedly connected with a fixed connection seat 6, and the fixed connection seat 6 is fixedly connected with a handle 7.

[0063] Further, the number of the fixed connection seats 6 is two, and the two fixed connection seats 6 are located on both sides of the lower insulating rod 1; two handles respectively fixedly connected to the two fixed connection seats 6 The distance between 7 is 30-50cm, which is easy to hold with both hands. The operator holds the lever with both hands to save physical strength, it is convenient to maintain the balance of the operating lever, and it is convenient to rotate and tighten with force.

Embodiment 3

[0065] Such as Figure 2-7 As shown in and 9, on the basis of embodiment two, further optimization, the outer upper part of the fastening nut 5 is fixedly equipped with a camera 8;

[0066] The number of the camera 8 is three, and its circumference is distributed on the fastening screw sleeve 5 in a row.

[0067] Further, an illuminating lamp 9 that provides brightness for the camera 8 is fixedly installed on the outer side of the threaded connection seat 4;

[0068] The number of said illuminating lamps 9 is three, and each illuminating lamp 9 is located between two cameras 8 .

[0069] The bottle with a higher height observes the condition of the bolt of the bottle through the camera, which is convenient for judging the position of the bolt and whether it is loose, and it is easy to tighten the screw sleeve to align the bolt for tightening operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com