Wood board drilling machine tool

A technology for wooden boards and machine tools, applied in fixed drilling machines, wood processing equipment, bark areas/debris/dust/waste removal, etc., can solve problems such as air pollution, low drilling accuracy, and generation of wood chips and dust , achieve less pollution, improve drilling quality and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

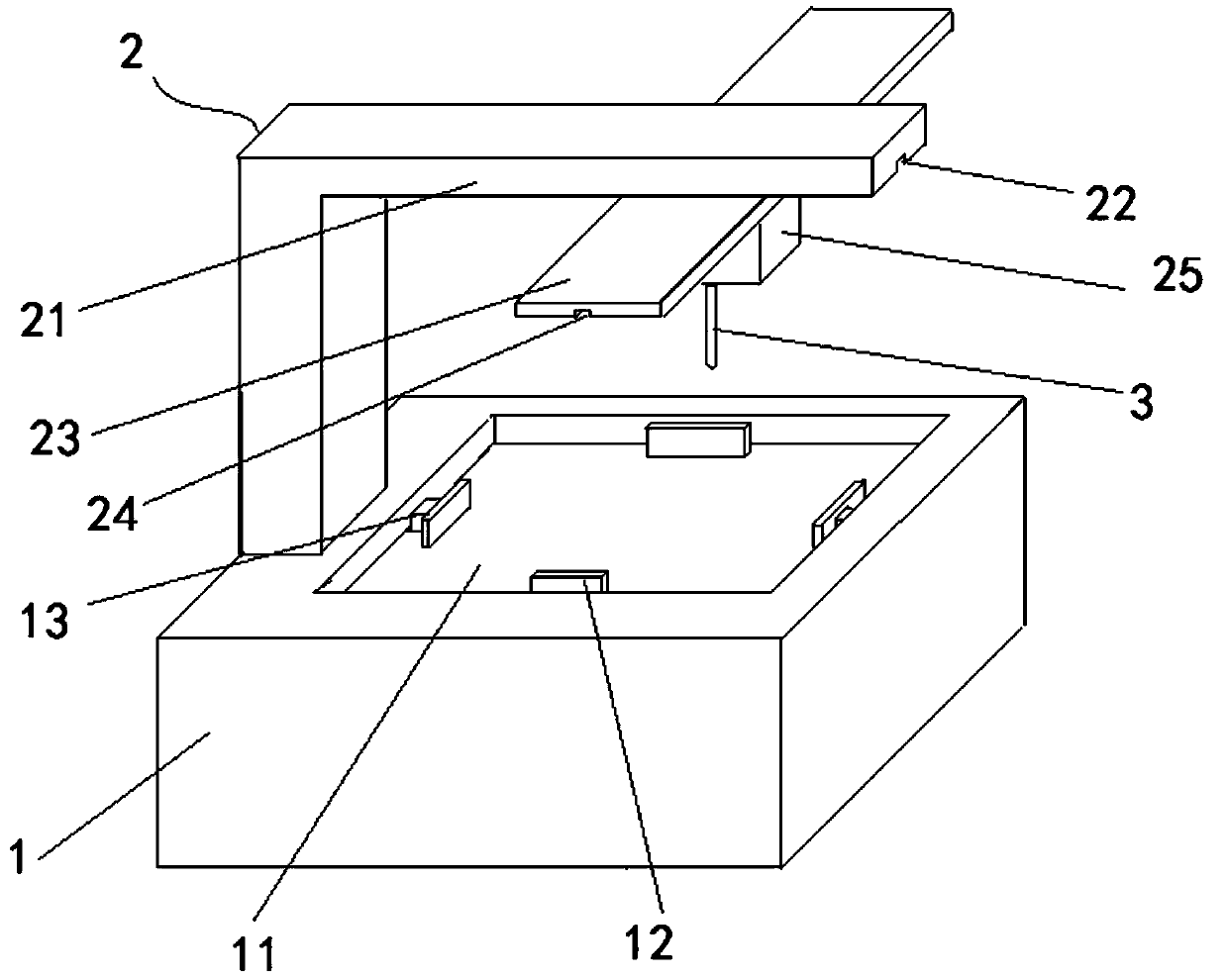

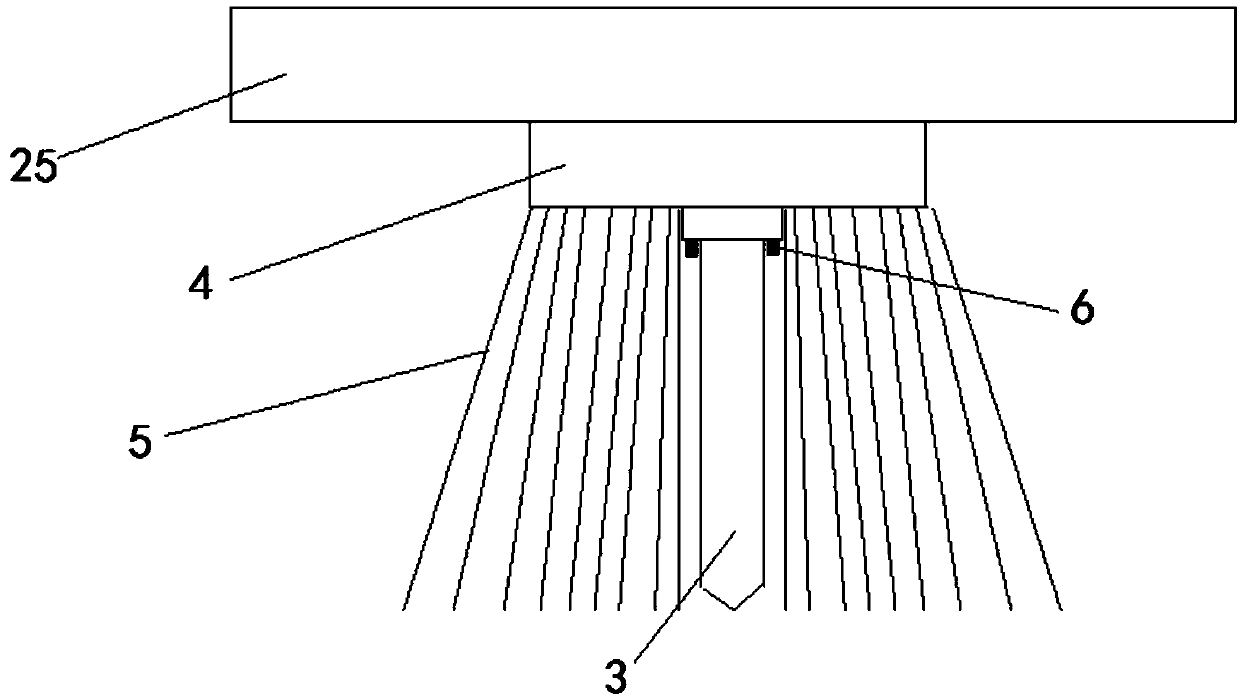

[0018] A kind of wooden plate drilling machine tool, its structure is as follows figure 1 , figure 2 As shown, it includes a machine tool table 1 for fixing wooden panels, a mobile platform 2 positioned above the wooden panel for installing a drill bit 3, and a cleaning unit arranged on the mobile platform 2, and the drill bit 3 is provided with a downwardly projected positioning unit ( figure 1 cleaning unit and positioning unit are not shown).

[0019] Wherein, a rectangular groove 11 is provided in the middle of the machine table 1, and a fixed plate 12 is provided at the midpoints of the four sides of the rectangular groove 11, and the rear end of the fixed plate 12 is connected to the main shaft of a linear motor 13. Put one or more boards side by side into the groove 11, and then four linear motors 13 push the four fixing boards 12 to the inside of the groove 11 until they touch the wooden boards, and the fixing boards 12 are used. This setting can be applied to Woode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com