Light release agent aid and use method thereof

A technology of light release and additives, applied in the direction of coating, etc., can solve the problems of reduced reactivity, affecting the short-term rapid reaction efficiency, affecting the usability and function of the finished release film, and achieving the effect of reducing the aging release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

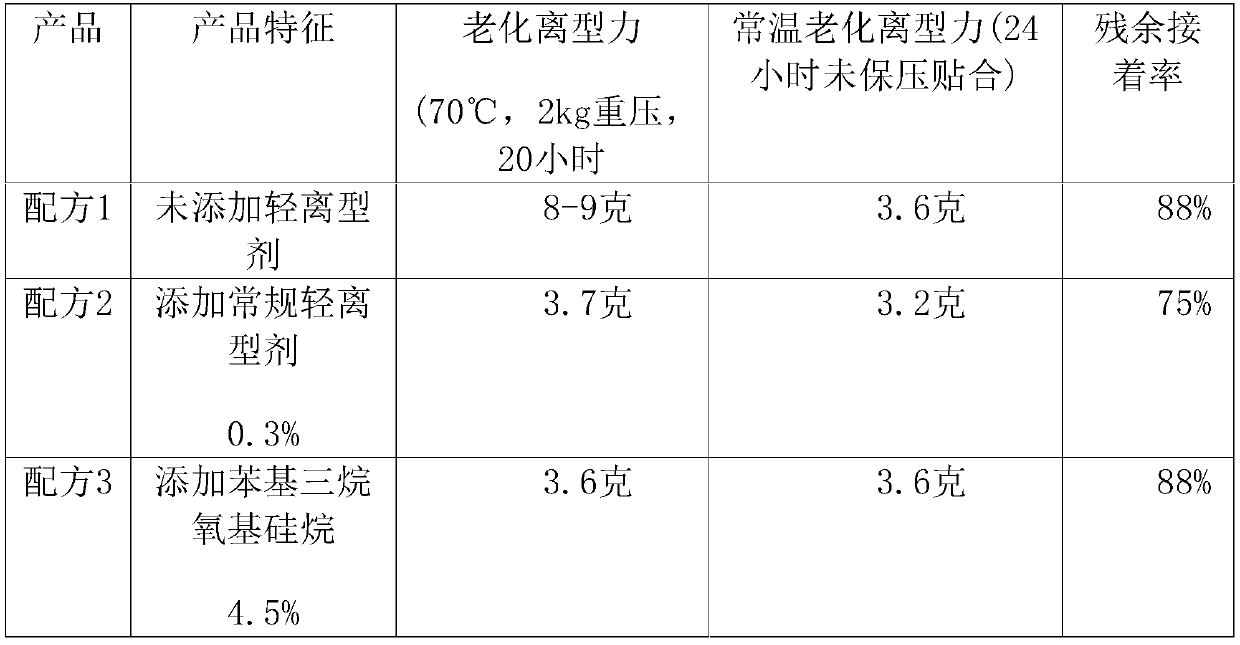

Examples

Embodiment 1

[0020] A light release agent additive, the main component of which is small molecular weight phenyltrialkoxysilane.

[0021] Another technical solution adopted by the present invention is a method for using a light release agent auxiliary agent, comprising the following specific steps:

[0022] (1) Add small molecular weight phenyltrialkoxysilane to the release agent silicone oil, add an appropriate amount of toluene, and mix thoroughly to obtain a mixed solution A.

[0023] (2) Add a small amount of vinyl silicone oil containing phenyl functional group or methyl silicone oil containing phenyl functional group into the mixed liquid and stir well to obtain mixed liquid B.

[0024] (3) Coating the mixed liquid B on the polyester film through the coating equipment and heating and curing to shape.

[0025] In step (2), the viscosity range of the phenyl functional group-containing vinyl silicone oil or phenyl functional group-containing methyl silicone oil is between 1000-3000 cps...

Embodiment 2

[0027] A light release agent additive, the main component of which is small molecular weight phenyldialkoxysilane.

[0028] Another technical solution adopted by the present invention is a method for using a light release agent auxiliary agent, comprising the following specific steps:

[0029] (1) Add small molecular weight phenyldialkoxysilane into the release agent silicone oil, add an appropriate amount of ethyl acetate, and mix thoroughly to obtain a mixed solution A.

[0030] (2) Add a small amount of vinyl silicone oil containing phenyl functional group or methyl silicone oil containing phenyl functional group into the mixed liquid and stir well to obtain mixed liquid B.

[0031] (3) Coating the mixed liquid B on the polyester film through the coating equipment and heating and curing to shape.

[0032] In step (1), the phenyldialkoxysilane is methylphenyldimethoxysilane.

[0033] In step (2), the viscosity range of the phenyl functional group-containing vinyl silicone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com