Repairing device for large shaft type part

A large-scale technology for shaft parts, which is applied to the field of repair devices for large-scale shaft parts, can solve the problems of long time consumption, economic losses of manufacturers, and shutdown of production processes of manufacturers, so as to shorten the repair cycle, reduce economic losses and repair costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

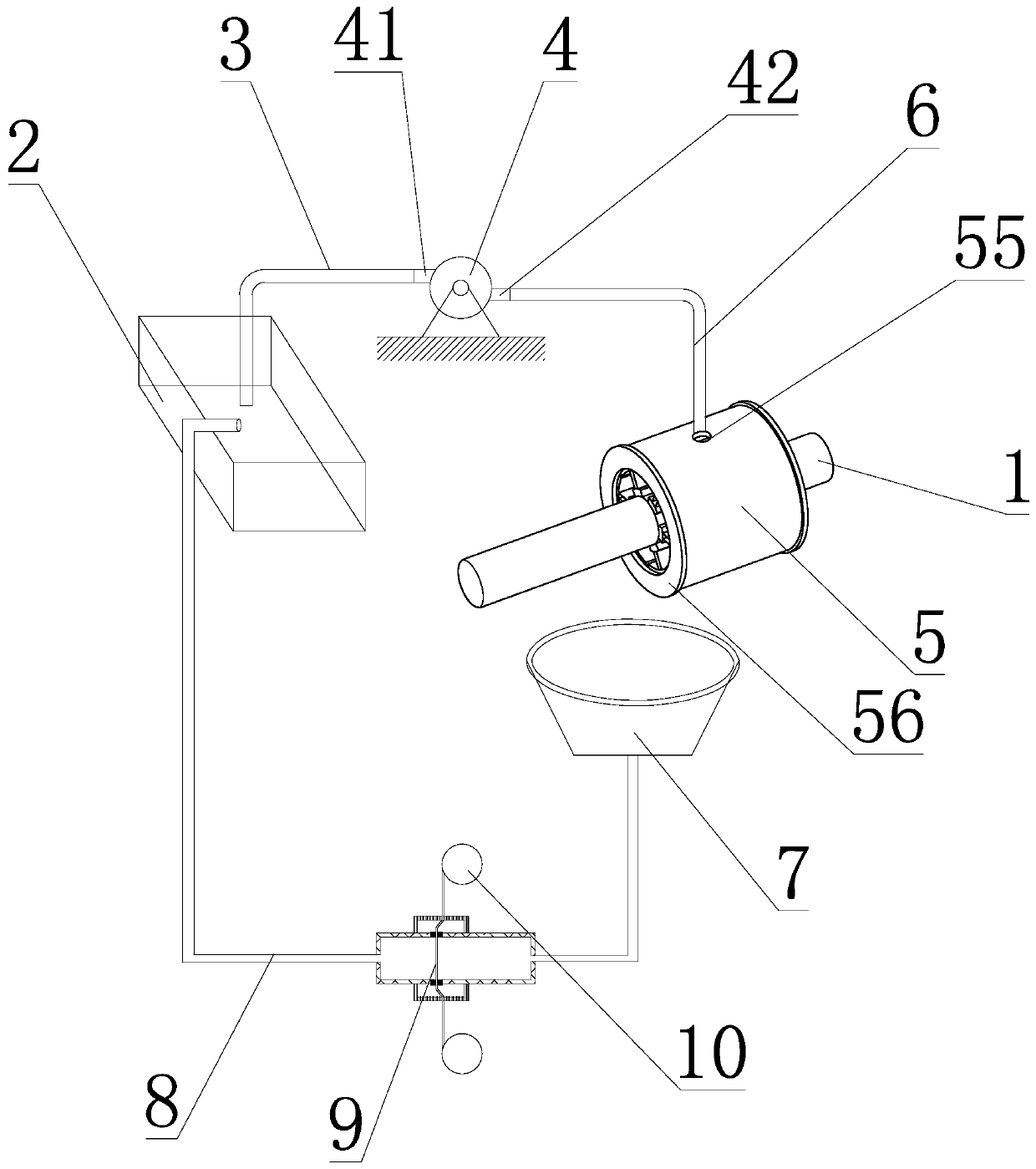

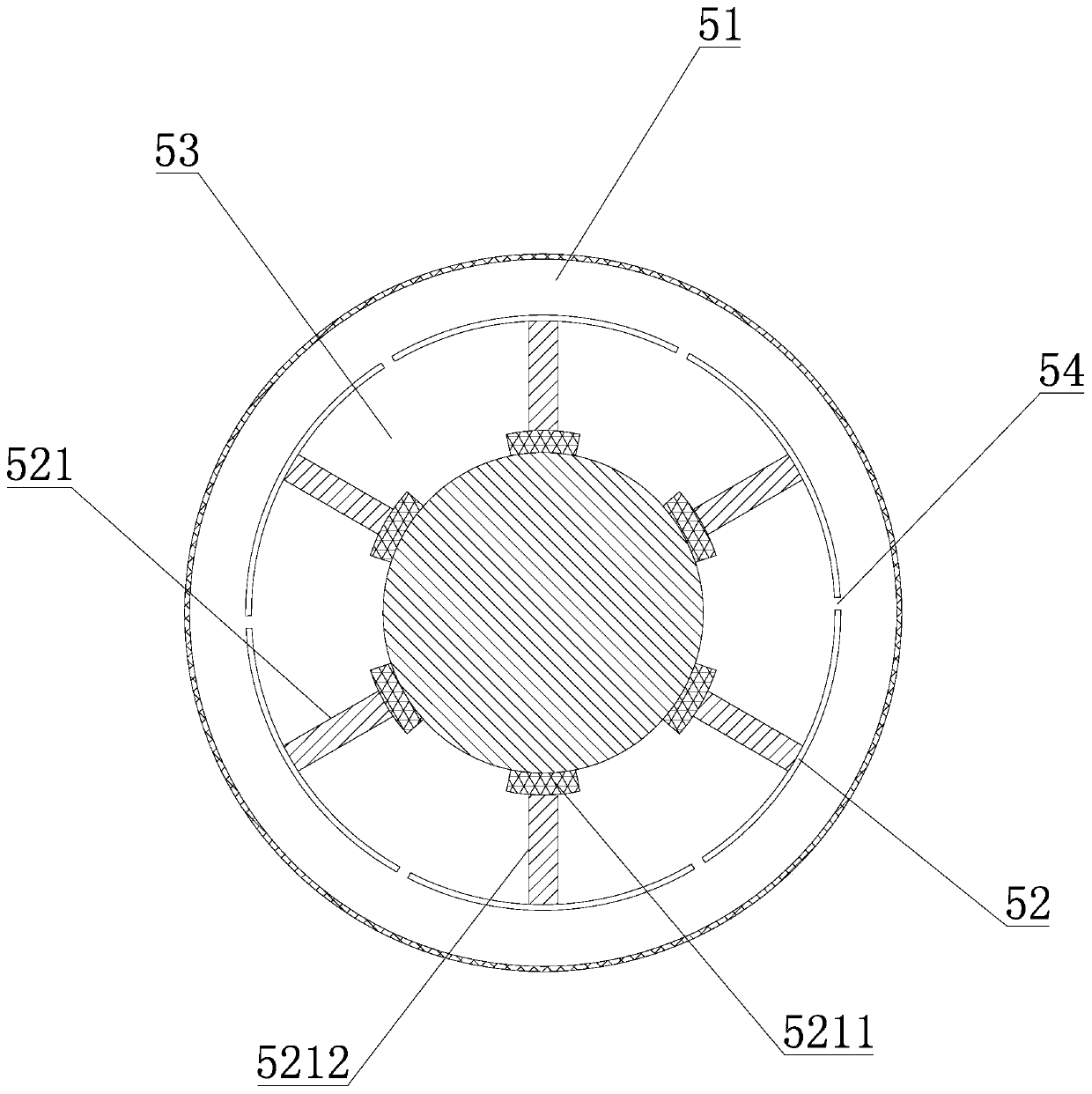

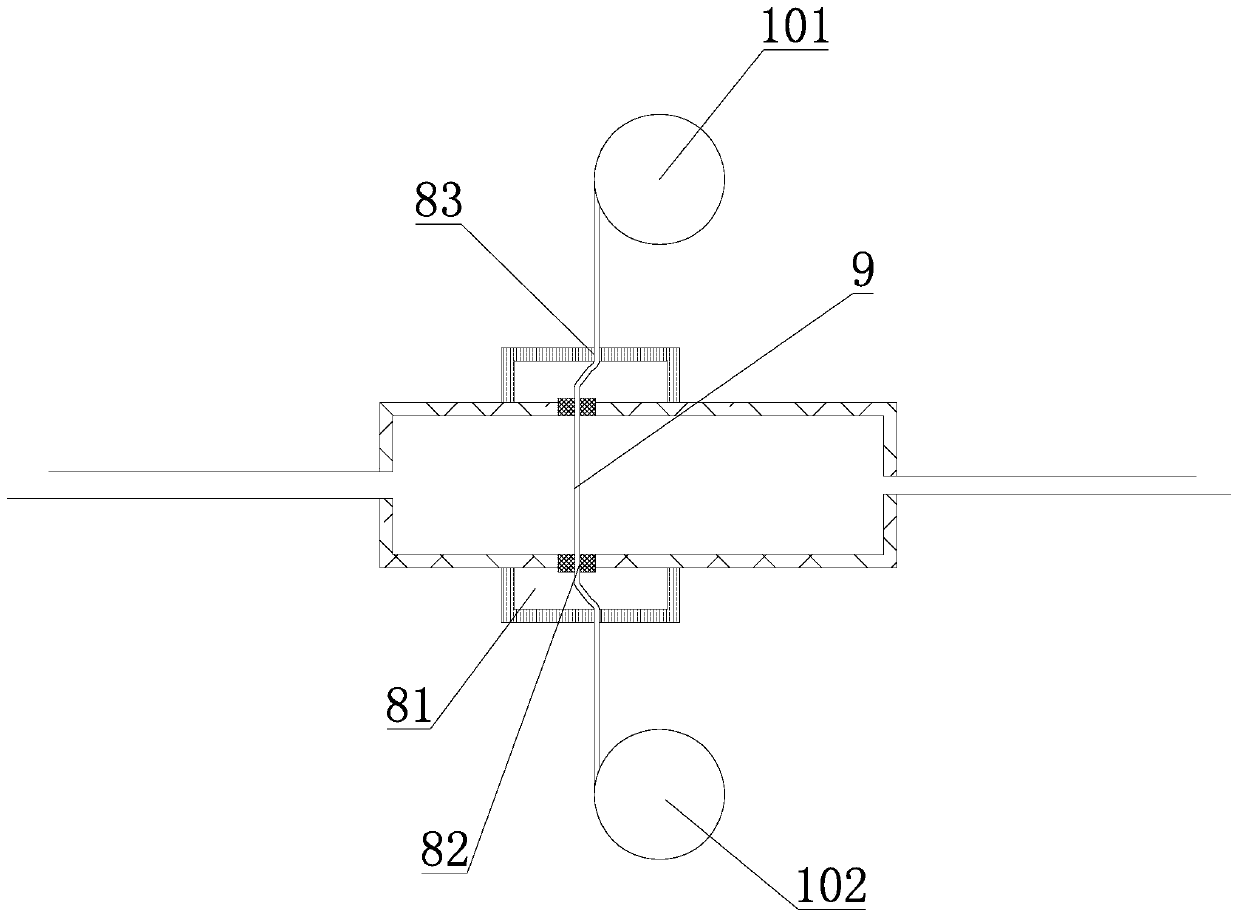

[0033] Such as Figure 1 to Figure 3 As shown, a repairing device for a large-scale shaft part includes a shaft part 1 to be repaired, and is characterized in that the other end of the liquid inlet pipe 3 connected to the liquid storage tank 2 equipped with alloy catalytic liquid is connected to the water pump 4 The water inlet 41 of the water pump is connected to the water outlet 42 of the water pump and the liquid distributor 5 sleeved at the position of the shaft parts to be repaired is connected through the liquid outlet pipe 6, and the bottom of the shaft parts is provided with a liquid collector for recovering the alloy catalytic liquid 7. The liquid collector is connected to the liquid storage tank through the liquid collecting pipe 8; the liquid uniform distributor includes the liquid storage chamber 51 of the outer ring and the liquid homogenizer 52 of the inner ring, and the liquid homogenizers of the liquid storage chamber and the liquid homogenizer The chamber 53 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com