A new type of pressure screen

A new type of pressure screen technology, applied in textile and papermaking, fiber raw material processing and other directions, can solve the problems of bolts falling into the pressure screen easily, time-consuming and labor consumption, loss, etc., so as to improve the pulping effect and reduce power. Consume and strengthen the effect of slag discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

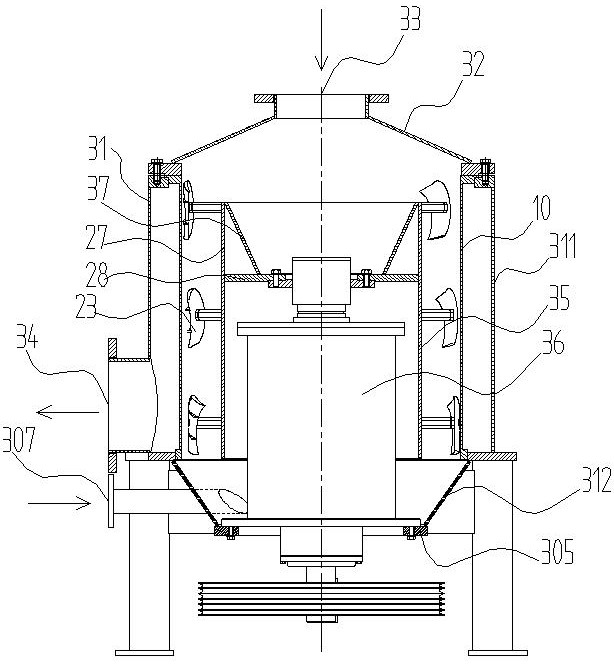

[0042] Such as Figure 1 to Figure 11 As shown, a new type of pressure screen in this embodiment includes a pressure screen housing 31, a pressure screen upper cover 32 is fixed on the upper end of the pressure screen housing 31, and a slurry feeding pipe 33 is provided on the pressure screen upper cover 32. A screen drum 10 is fixed inside the pressure screen housing 31, and the screen drum 10 is fixed on the pressure screen housing 31 through a screen drum installation structure. A slurry outlet pipe 34 is provided on the pressure screen housing 32 corresponding to the bottom of the screen drum. A rotor 35 is provided inside the screen drum 31 .

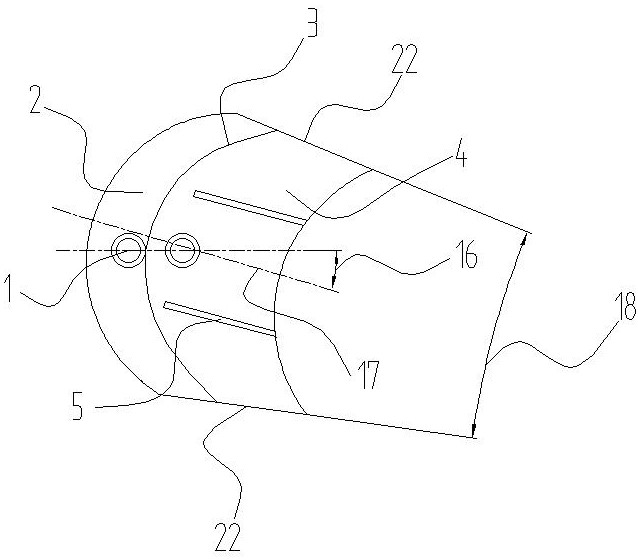

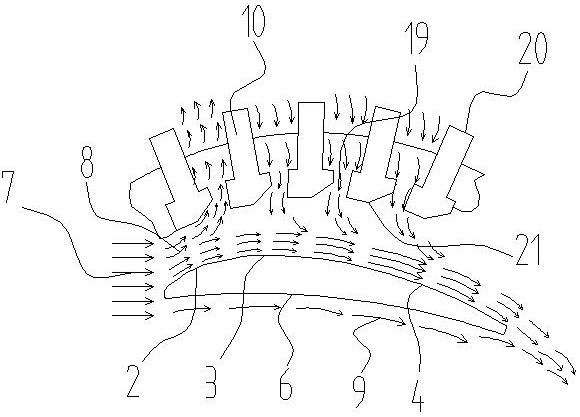

[0043] The rotor 35 includes a rotor cylinder 27, and the outer periphery of the rotor cylinder 27 is evenly layered with several fin fixing rods 26, which are divided into several layers, and each layer is evenly distributed in the circumferential direction, and rotor blades are installed at the ends of the fin fixing rods. Shee...

Embodiment 2

[0079] The rotor blade 23 in this embodiment is used for the updraft screen, and the range of the included angle 16 is -(12°-18°).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com