A kind of processing method of wave filter

A processing method and filter technology, which can be used in heating/cooling fabrics, textiles, papermaking, etc., can solve the problems of low filtration efficiency, poor filtration quality, and high filtration efficiency of a single-layer filter, so as to improve filtration quality and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Such as Figure 4 and Figure 5 Shown, a kind of processing method of corrugated filter screen comprises the following steps:

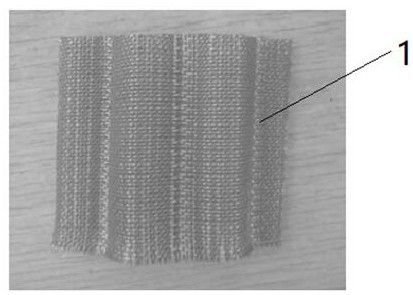

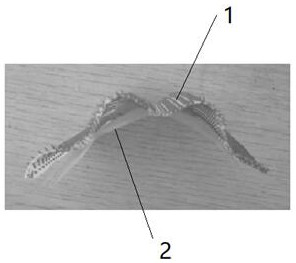

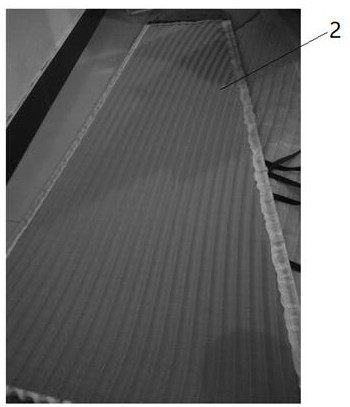

[0038] S1. The wave-shaped filter includes surface layer 1 and bottom layer 2. Surface layer 1 adopts 3-shed twill structure, and the bonding of surface layer 1 and bottom layer 2 also adopts 3-shed twill structure. In the twill structure of surface layer 1, every 42 warps Back adjacent 3 are used for binding the warp of surface layer 1 and bottom layer 2, surface layer 1 mid-latitude thread and bottom layer 2 mid-latitude threads can adopt the fiber of different sizes, and the section diameter ratio of surface layer 1 weft thread and bottom layer 2 weft threads is 3: 1;

[0039] S2. The overall weaving of the wave-shaped filter screen adopts 6 sheds, the surface layer 1 of the wave-shaped filter screen is woven with polyester monofilament, and the bottom layer 2 of the wave-shaped filter screen is woven with nylon monofilament; the 6-shed th...

Embodiment 2

[0042] Such as Figure 6 and Figure 7 Shown, a kind of processing method of corrugated filter screen comprises the following steps:

[0043]S1. The wave-shaped filter includes surface layer 1 and bottom layer 2. Surface layer 1 adopts 3-shed twill structure. The bonding of surface layer 1 and bottom layer 2 also adopts 3-shed twill structure. In the twill structure of surface layer 1, every 51 warps Back adjacent 3 are used for binding the warp of surface layer 1 and bottom layer 2, surface layer 1 mid-latitude thread and bottom layer 2 mid-latitude threads can adopt the fiber of different sizes, and the section diameter ratio of surface layer 1 weft thread and bottom layer 2 weft threads is 3: 1;

[0044] S2. The overall weaving of the wave-shaped filter screen adopts 12 sheds, the surface layer 1 of the wave-shaped filter screen is woven with polyester monofilament, and the bottom layer 2 of the wave-shaped filter screen is woven with nylon monofilament; among them, 12 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com