Coating raw material treatment device for plastic-coated steel pipe

A technology of raw material processing and plastic-coated steel pipes, which is applied in the direction of promoting the drying of solid materials, such as the preliminary treatment of dry goods, the treatment of dry goods, and the drying of solid materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

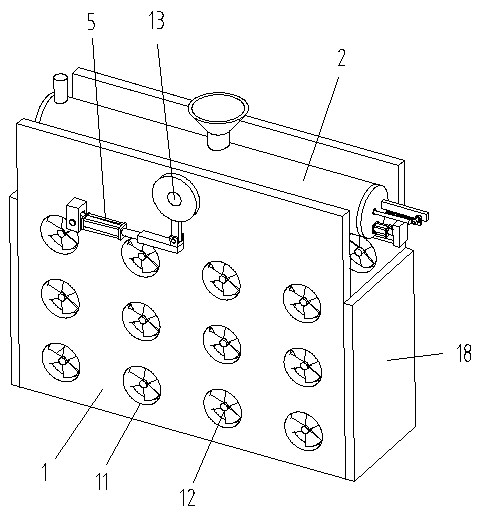

[0028] Such as Figure 1-Figure 9 As shown, a coating raw material processing device for plastic-coated steel pipes provided by the present invention includes two vertical plates 1 arranged in parallel, and the two vertical plates 1 are fixedly connected by two connecting plates 18. On each vertical plate 1 All are provided with a plurality of fan holes 11, each fan hole 11 is equipped with a heater 12, the heaters 12 on the two vertical plates 1 are relatively arranged, each vertical plate 1 is provided with a rotating hole, and the two Two rotating holes are coaxially arranged, and a rotating shaft 13 is rotated and fitted in each rotating hole, and the pretreatment device 2 is fixedly connected between the two rotating shafts 13 .

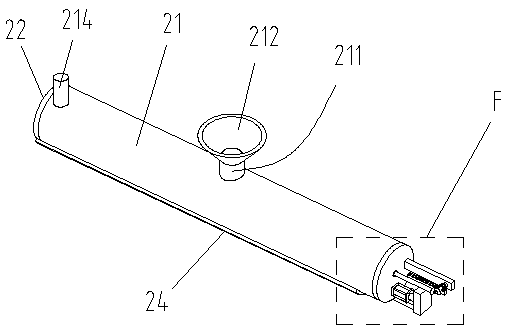

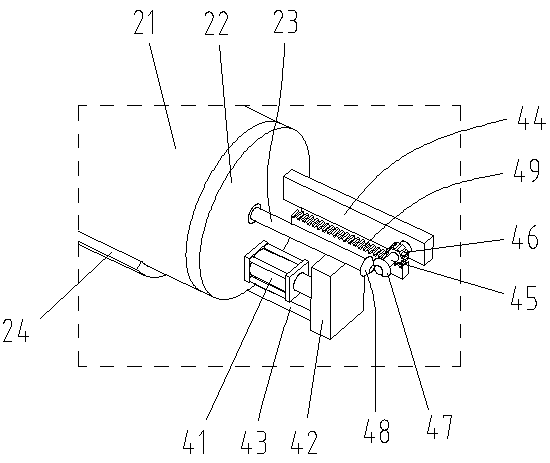

[0029] The pretreatment device 2 includes a round tube 21, two rotating shafts 13 are symmetrically fixedly connected in the middle of the round tube 21, the round tube 21 rotates between the two vertical plates 1 through the two rotating shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com