Power testing device and method based on forward-tilting beam

A power test and beam technology, applied in the field of electronics, can solve the problems of deviation of test direction, high test uncertainty of small targets, inability to detect accurately, etc., and achieve the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

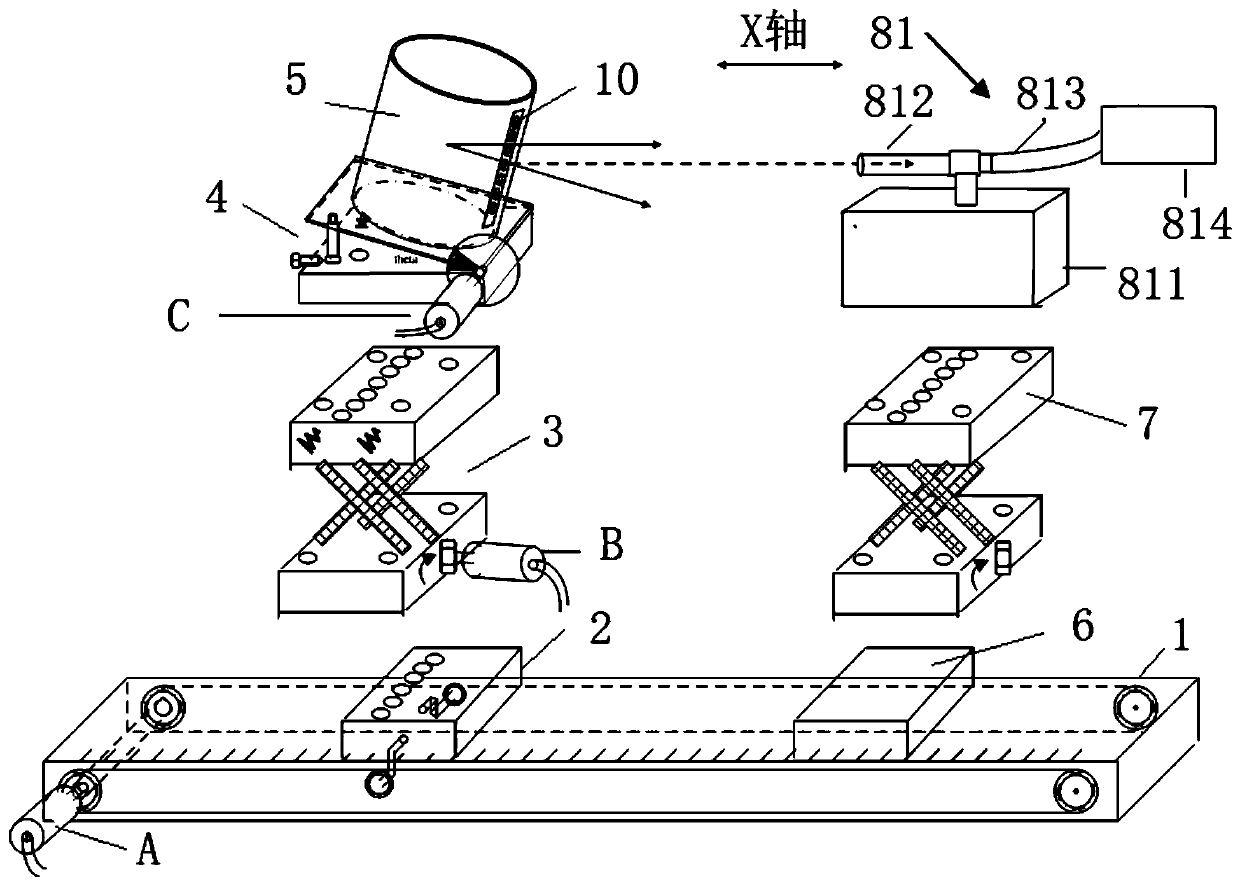

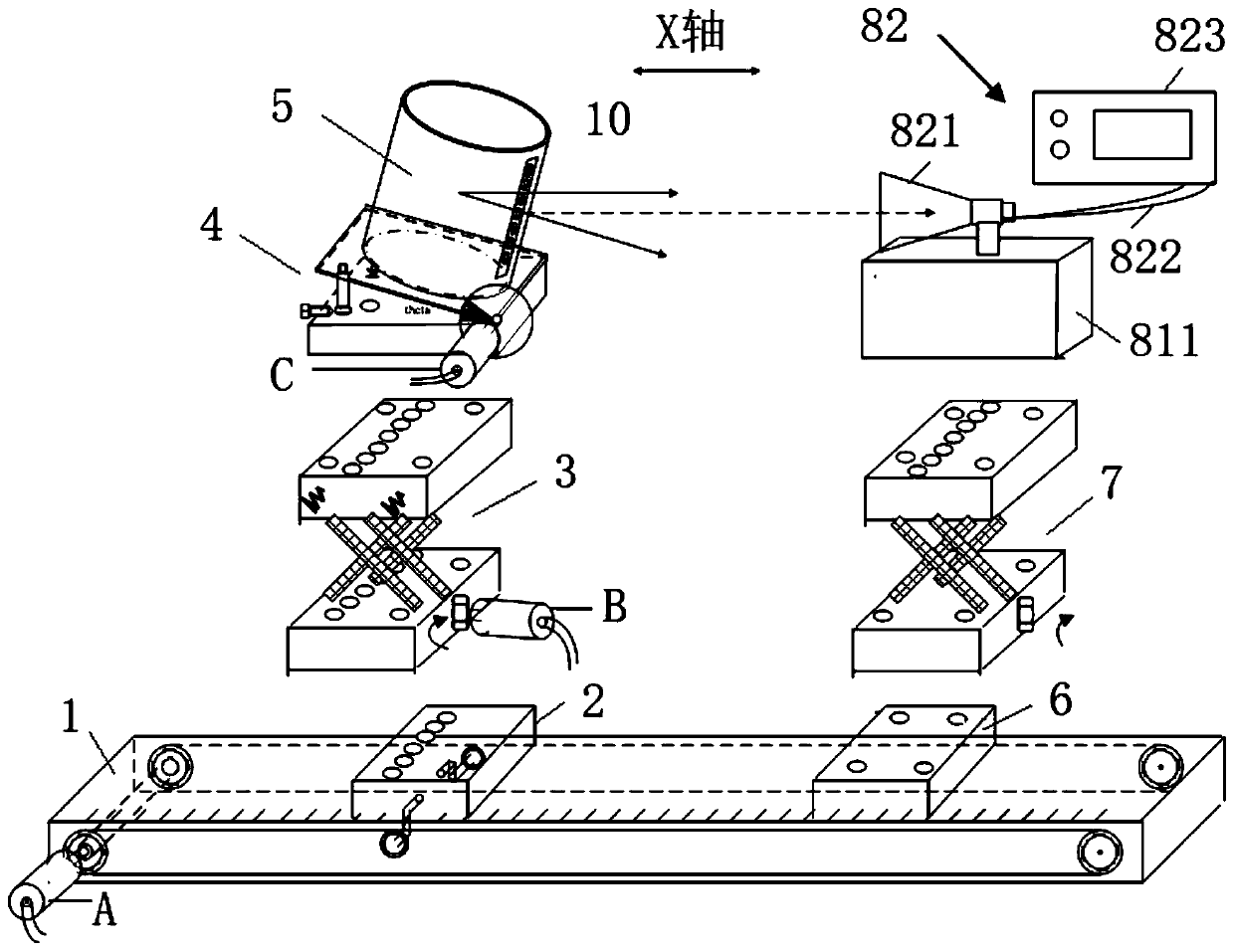

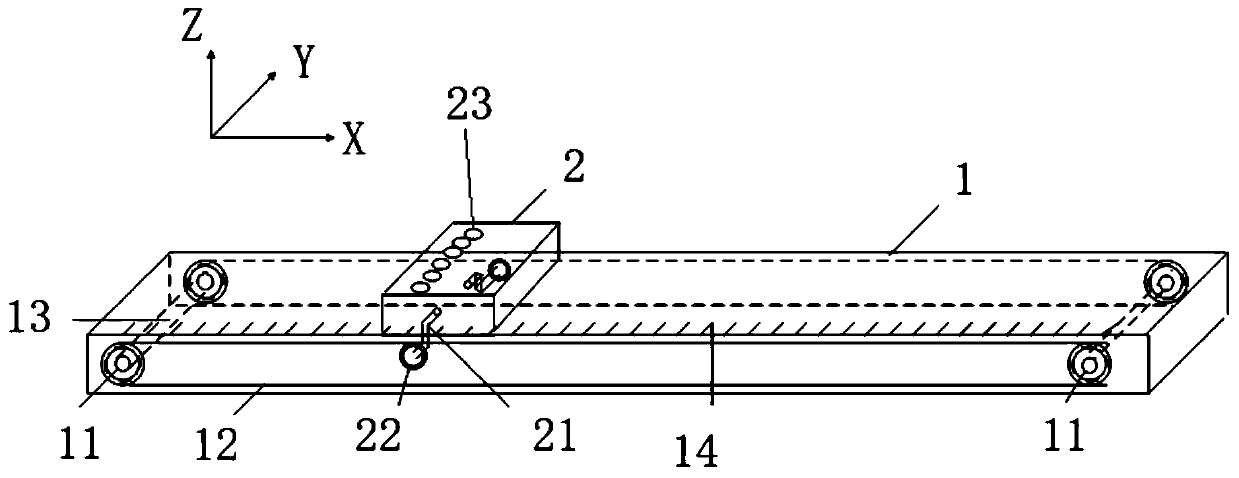

[0069] Such as Figure 1-2 Shown is a power test device based on a forward tilt beam according to an embodiment of the present invention, which is used to test the power of the forward tilt beam to be tested, including a support platform 1, installed on the support platform 1 from bottom to top The X-direction mobile stage 2, the first lifting bracket 3, the triangular tilting bracket 4 and the antenna bracket 5 connected in sequence, and the fixed stage 6 and the second lifting bracket installed on the support platform 1 and connected sequentially from bottom to top 7 and switchable laser emitting unit 81 and millimeter wave transceiver unit 82. An antenna to be tested 10 is mounted on the antenna bracket 5, and the antenna to be tested 10 is a mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com