Adsorption device and desorption system

An adsorption device and desorption technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as high energy consumption, high requirements for terminal treatment equipment, and large fluctuations in concentration changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

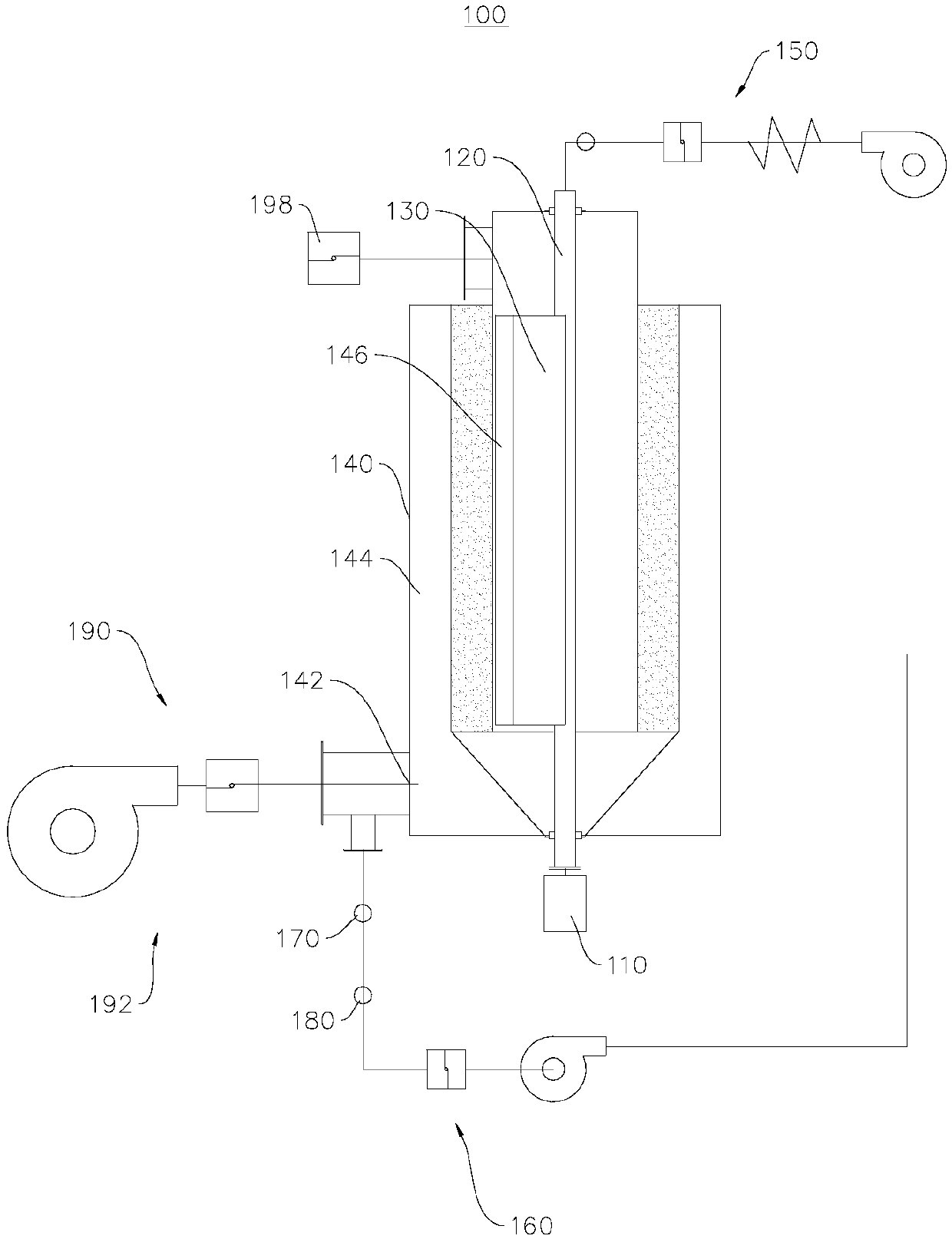

[0044] see figure 1 , this embodiment provides an adsorption device 100, and the adsorption device 100 provided by this embodiment can improve the effect of desorption.

[0045]The adsorption device 100 provided in this embodiment can adsorb organic molecules in the organic raw gas, filter the organic raw gas into filtered gas, and also allow the raw gas to absorb organic molecules in the adsorption device 100 to form high-concentration organic waste gas.

[0046] see figure 1 , in this embodiment, the adsorption device 100 includes a driver 110, a nozzle 120, an adsorption layer 130 and a housing 140, the adsorption layer 130 is arranged in the housing 140, and the housing 140 is divided into an inner cavity 144 and an outer cavity 146, The nozzle 120 is disposed within the inner cavity 144;

[0047] The nozzle 120 is used to introduce the preheated raw gas into the inner chamber 144;

[0048] The driver 110 is connected to the nozzle 120, and is used to drive the nozzle 1...

Embodiment 2

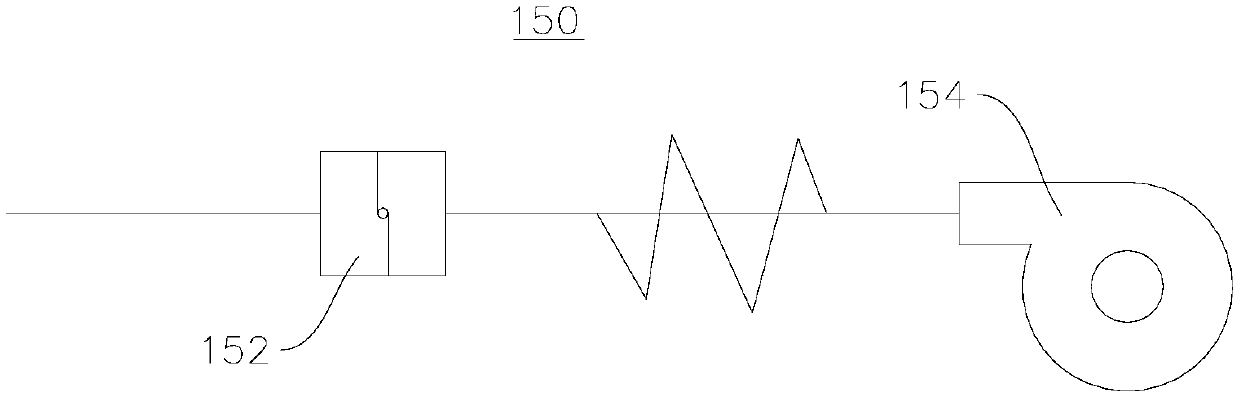

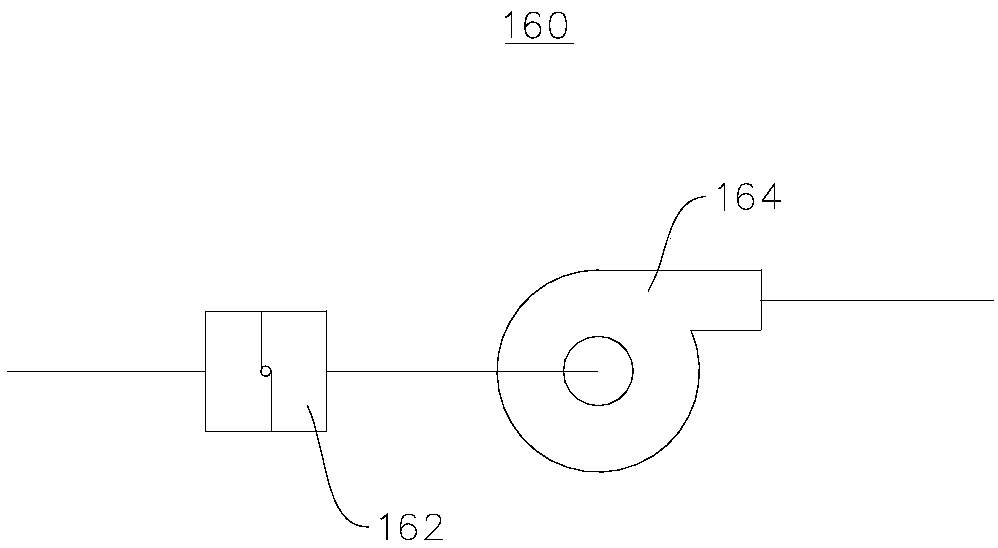

[0081] see Figure 5 , this embodiment provides a desorption system 10, and the desorption system 10 provided by this embodiment can improve the effect of desorption.

[0082] For brief description, for the parts not mentioned in this embodiment, reference may be made to Embodiment 1.

[0083] In this embodiment, the desorption system 10 includes a treatment device 200 and the adsorption device 100 provided in the first embodiment. The treatment device 200 is connected with the outlet fan 164 for treating organic waste gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com