Sealing mixing storage device for siliconizing fluid of medical syringe needle

A technology of silicification treatment and storage device, which is applied to the storage device of medical needle tip silicification treatment liquid and the field of medical needle needle silicification treatment device, can solve the problems of destroying atmospheric ozone, potential safety hazards, increasing the consumption of silicone oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

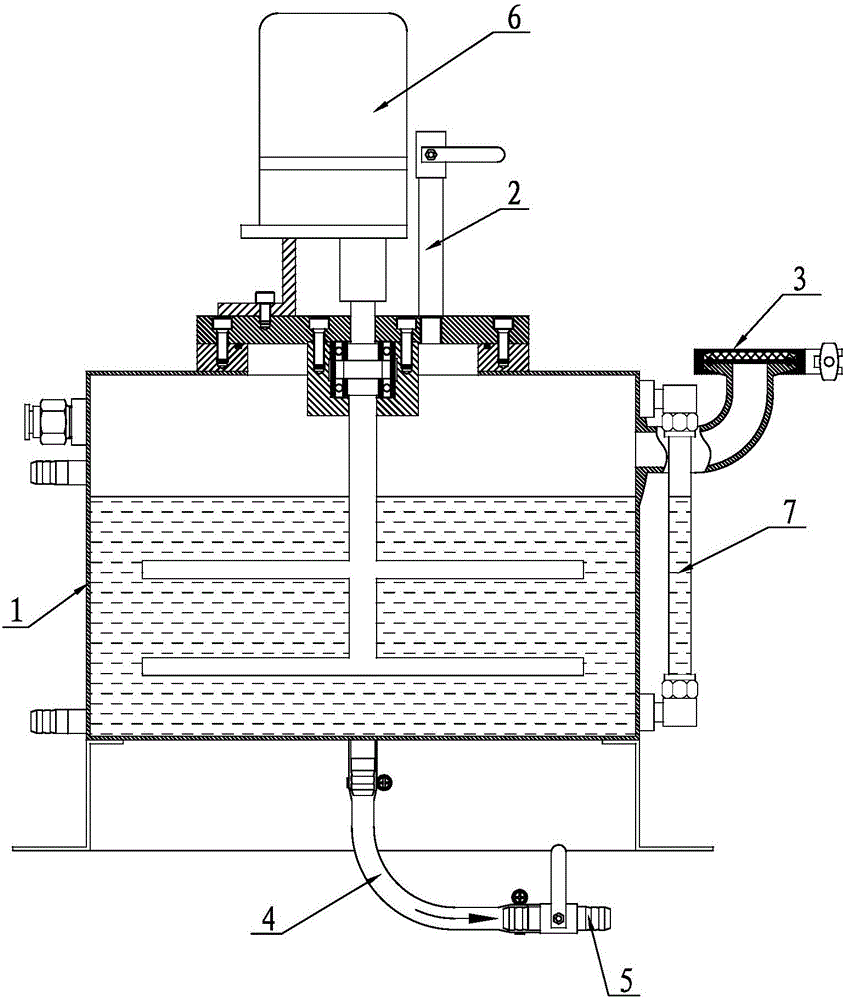

[0022] Embodiment 1: A kind of airtight homogeneous storage device for medical needle siliconization treatment liquid, such as image 3 As shown, it includes a fuel storage tank 1, a one-way pressure balance valve 2, a controllable oil nozzle 3, an oil discharge pipe 4, an oil discharge valve 5 and a stirring device 6. The controllable fuel nozzle 3 is arranged on the fuel storage tank 1, and is connected with the 1 inner cavity is connected, and the treatment liquid mixed with silicone oil and diluent is injected into the oil storage tank 1 through the controllable oil nozzle 3; One end of the oil discharge pipe 4 communicates with the bottom of the inner cavity of the oil storage tank 1, and the other end of the oil discharge pipe 4 communicates with the outside world through the oil discharge valve 5. The stirring member in the stirring device 6 is arranged in the oil storage tank 1, and is located Inside, the stirring element is driven by a motor.

Embodiment 2

[0023] Embodiment 2: On the basis of Embodiment 1, a liquid level display tube 7 is added. The liquid level display tube 7 is arranged on any side of the fuel storage tank 1, and the lower end of the liquid level display tube 7 is connected to the bottom of the inner cavity of the fuel storage tank 1. In communication, the upper end of the liquid level display tube 7 communicates with the upper part of the air cavity in the oil storage tank 1 .

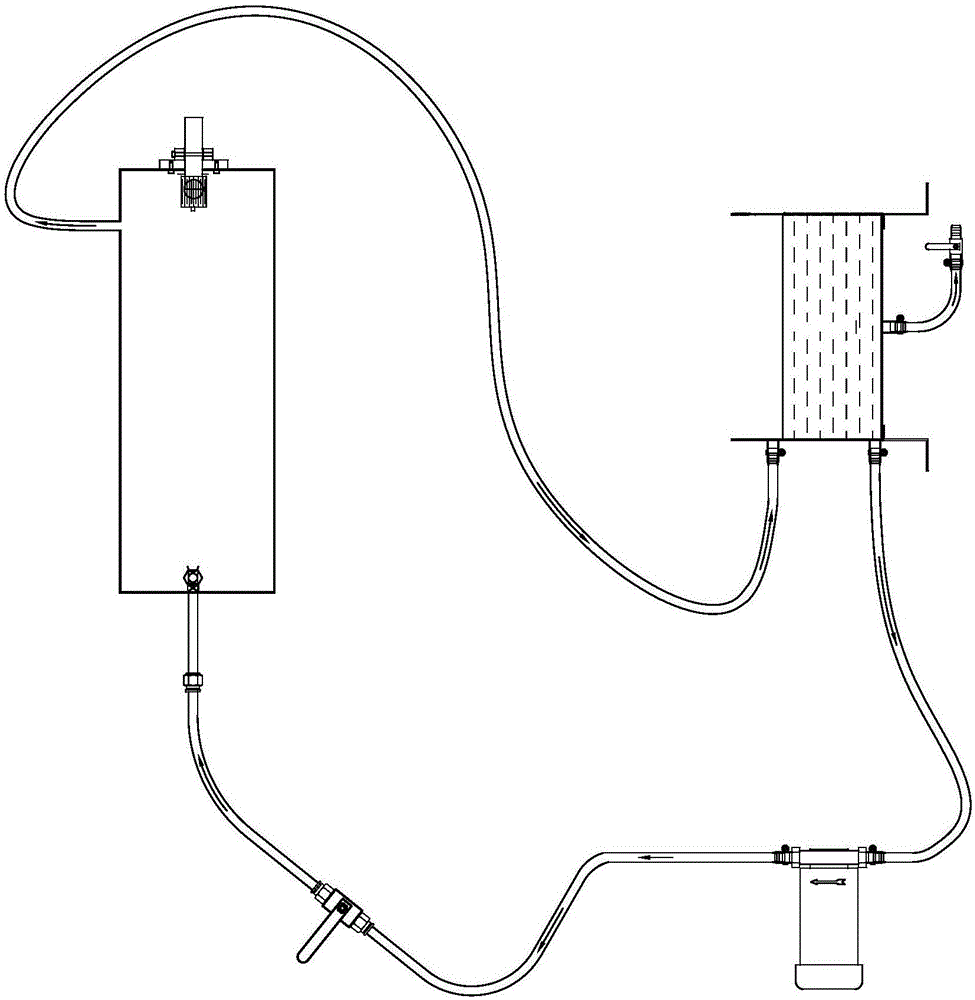

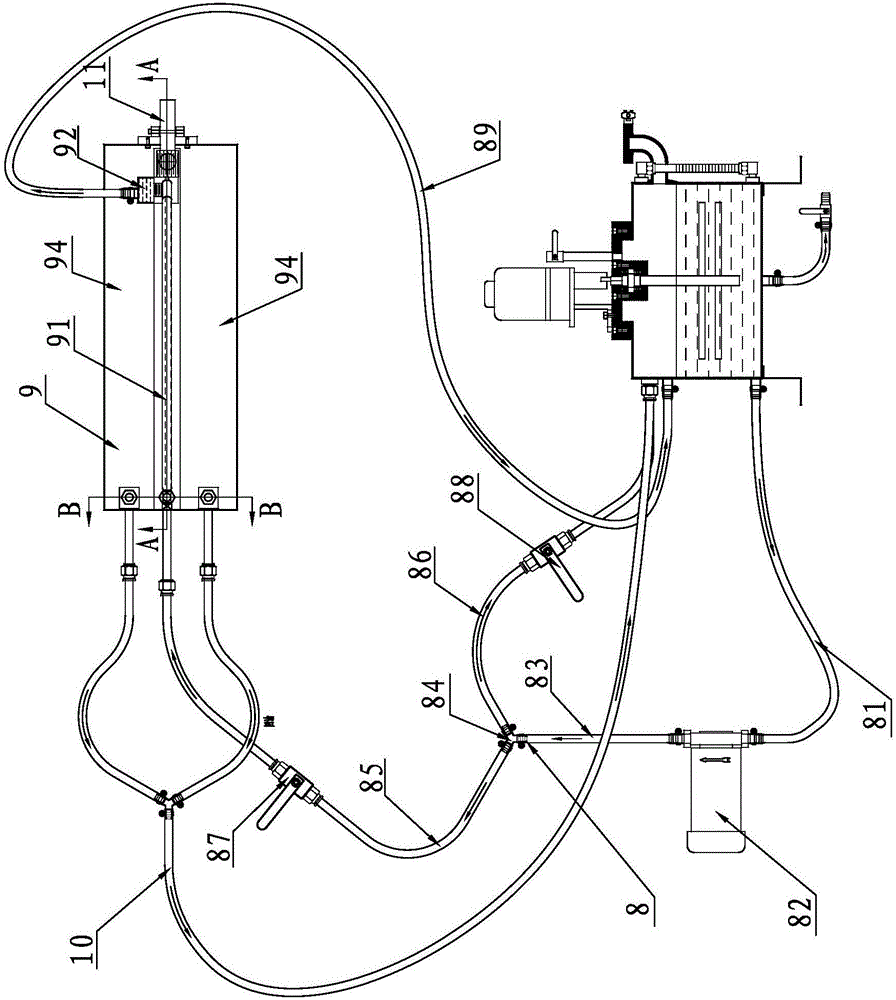

[0024] A kind of medical needle siliconization treatment liquid supply system containing the present invention, such as Figure 2 to Figure 6 As shown, on the basis of the present invention, an adjustable oil delivery device 8, a siliconization treatment pool 9, an oil overflow return device 10 and a liquid level control device 11 are added, and the adjustable oil delivery device 8 includes an oil suction pipe 81, an oil delivery pump 82 , an oil outlet pipe 83, a three-way joint 84, an oil supply pipeline 85, a shunt pipeline 86, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com