A kind of preparation method and application of iridium oxide nanoparticle catalyst

A technology of nanoparticles and iridium oxide, which is applied in the field of preparation of iridium oxide nanoparticle catalysts, can solve the problems of high preparation cost, small specific surface area of iridium oxide, and low catalytic activity, and achieve high Tafel slope, excellent oxygen evolution activity, and improved The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

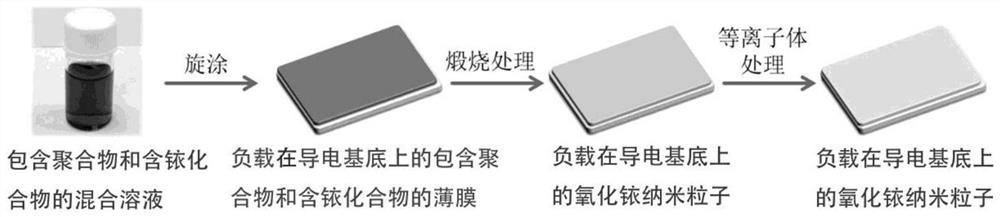

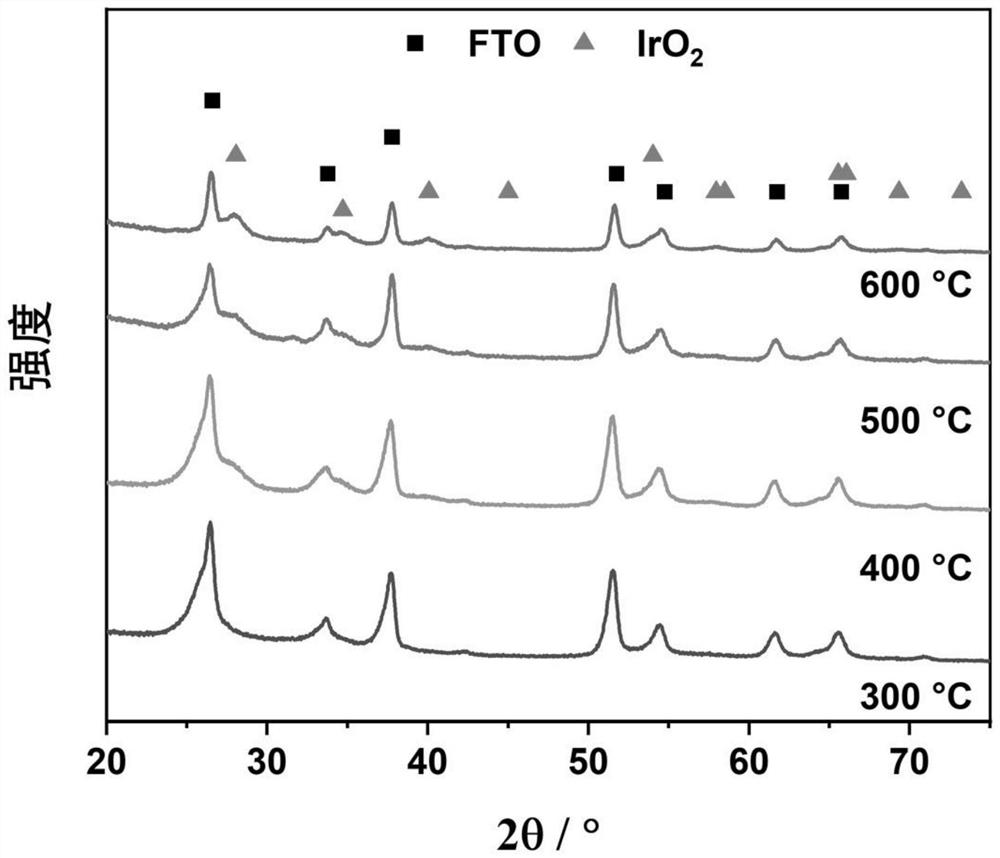

[0039] A preparation method of an iridium oxide nanoparticle catalyst, specifically comprising the following steps:

[0040] Step 1: The FTO conductive substrate is placed in acetone and ethanol in turn and treated with ultrasonic cleaning for 5-15 minutes, then the ultrasonically treated FTO conductive substrate is cleaned with deionized water and dried, and finally the dried FTO conductive substrate is washed with plasma The generator cleaning machine was treated in an air atmosphere for 15 minutes to obtain the treated FTO conductive substrate.

[0041] Step 2: Disperse chloroiridic acid and polyvinylpyrrolidone in deionized water to prepare a mixed solution, the mass fraction of chloroiridic acid in the mixed solution is 0.5%, and the mass fraction of polyvinylpyrrolidone is 1%. Mix the solution and uniformly coat the mixed solution on the treated FTO conductive substrate by a spin coater. When coating, the spin coater firstly distributes the glue at 500r / min for 10 second...

Embodiment 2

[0046] A preparation method of an iridium oxide nanoparticle catalyst, specifically comprising the following steps:

[0047] Step 1: The FTO conductive substrate is placed in acetone and ethanol in turn and treated with ultrasonic cleaning for 5-15 minutes, then the ultrasonically treated FTO conductive substrate is cleaned with deionized water and dried, and finally the dried FTO conductive substrate is washed with plasma The generator cleaning machine was treated in an air atmosphere for 15 minutes to obtain the treated FTO conductive substrate.

[0048] Step 2: Disperse chloroiridic acid and polyvinylpyrrolidone in deionized water to prepare a mixed solution. The mass fraction of chloroiridic acid and polyvinylpyrrolidone in the mixed solution is 20%, and the mass fraction of polyvinylpyrrolidone is 20%. Mix the solution and uniformly coat the mixed solution on the treated FTO conductive substrate by a spin coater. When coating, the spin coater firstly distributes the glue ...

Embodiment 3

[0053] A preparation method of an iridium oxide nanoparticle catalyst, specifically comprising the following steps:

[0054] Step 1: The FTO conductive substrate is placed in acetone and ethanol in turn and treated with ultrasonic cleaning for 5-15 minutes, then the ultrasonically treated FTO conductive substrate is cleaned with deionized water and dried, and finally the dried FTO conductive substrate is washed with plasma The generator cleaning machine was treated in an air atmosphere for 15 minutes to obtain the treated FTO conductive substrate.

[0055] Step 2: Disperse chloroiridic acid and polyvinylpyrrolidone in deionized water to prepare a mixed solution, the mass fraction of chloroiridic acid in the mixed solution is 5%, and the mass fraction of polyvinylpyrrolidone is 10%. Mix the solution and uniformly coat the mixed solution on the treated FTO conductive substrate by a spin coater. When coating, the spin coater firstly distributes the glue at 500r / min for 10 seconds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com