Machine case special locating and installing equipment with deviation prevention function

A positioning and installation, anti-dislocation technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as increased production costs, poor positioning effect, and impact on product processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

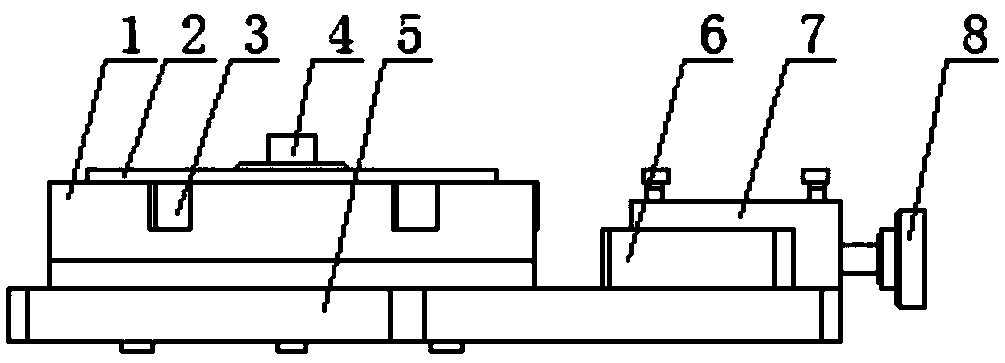

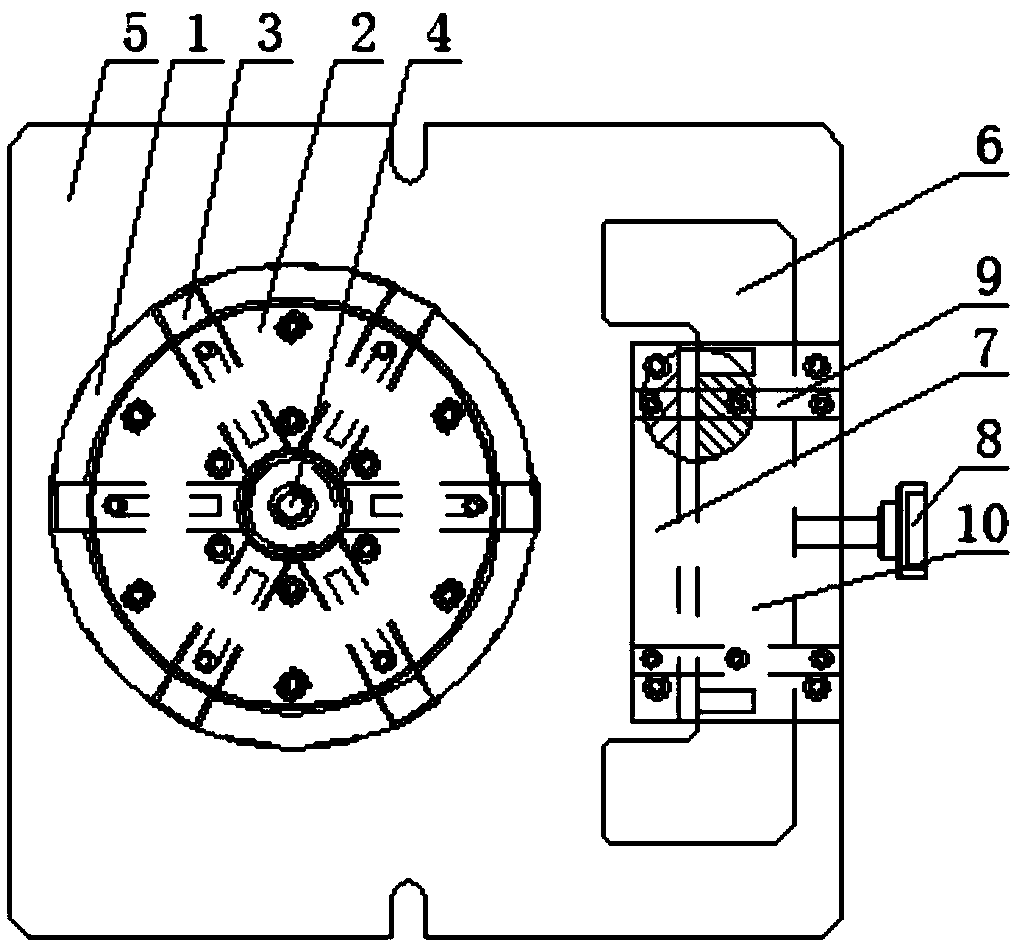

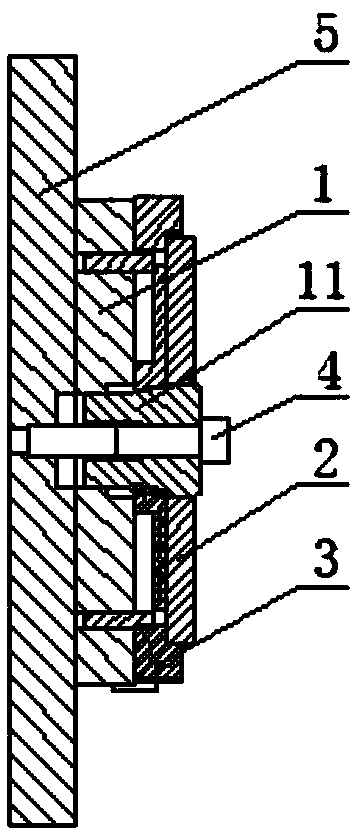

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0018] A special positioning and installation device for the casing with the function of preventing dislocation, including a bottom plate 5, a central positioning plate 1, a top screw 4, a top block 3, a cover plate 2, a tapered sleeve 11 and an anti-misplacement mechanism, and the axis center on the upper surface of the bottom plate A central positioning plate is coaxially installed, and a tapered sleeve is coaxially installed on the upper surface of the central positioning plate. A plurality of chutes are made on the upper surface of the central positioning plate outside the tapered sleeve, and a top is placed in each chute. block, the chute and the top block are evenly distributed along the circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com