Plastic pipe production equipment

A technology for producing equipment and plastic pipes, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of difficult pipe cooling or cleaning, inability to deliver finished products to designated points, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

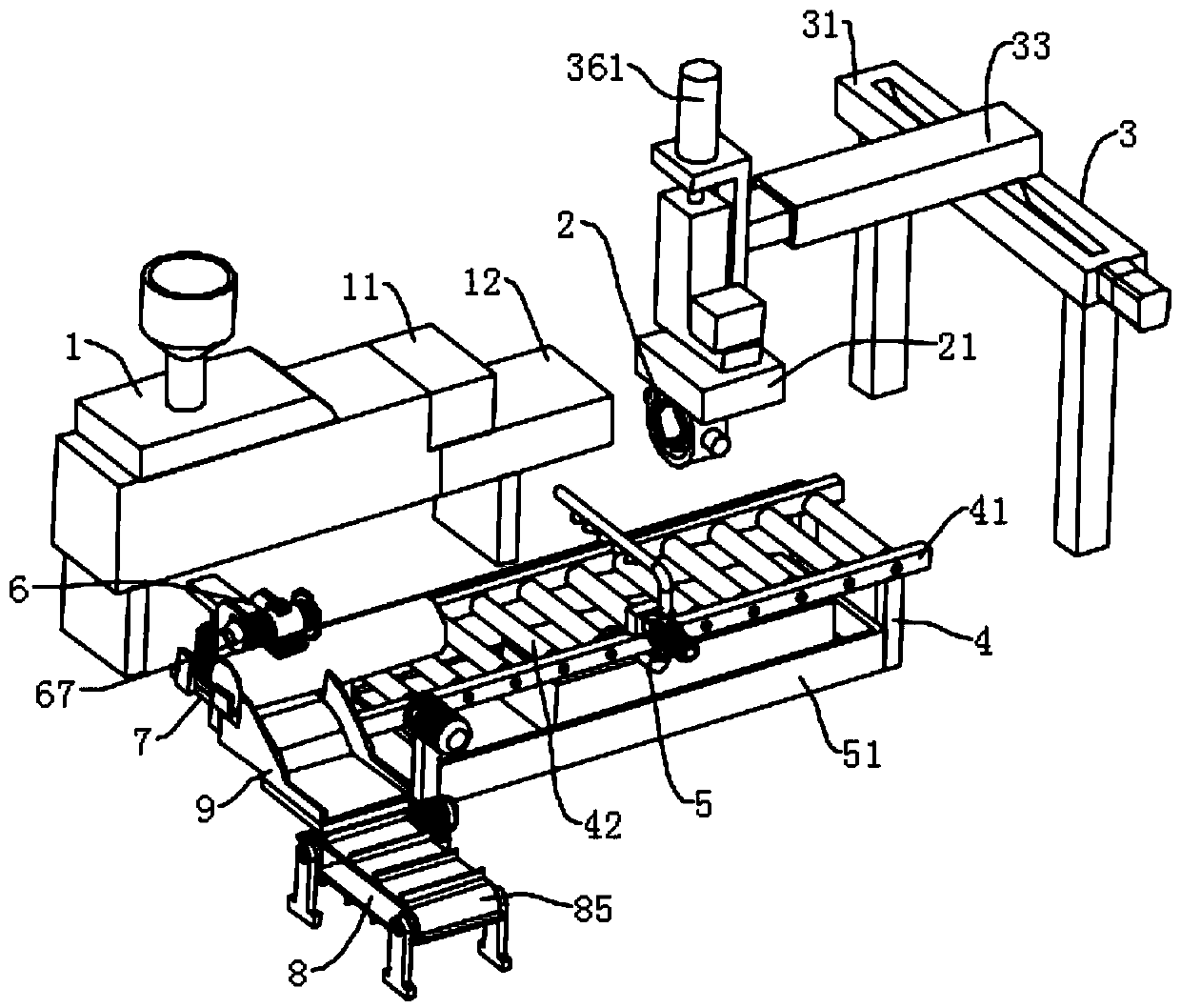

[0047] refer to figure 1 , a plastic pipe production equipment, including injection molding machine 1 and pipe injection mold 11, also includes:

[0048] A bearing platform 12 for carrying injection-molded pipe products;

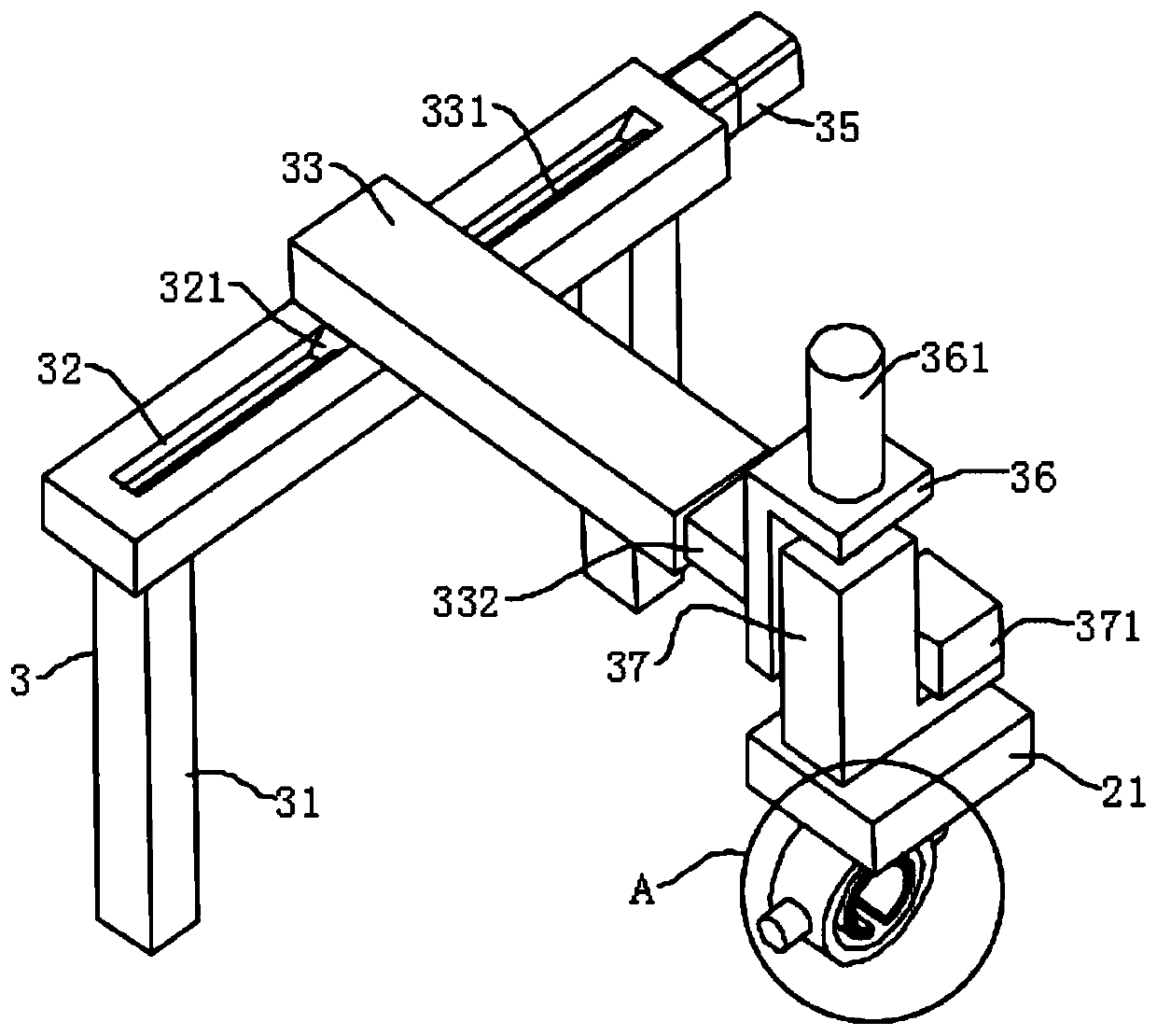

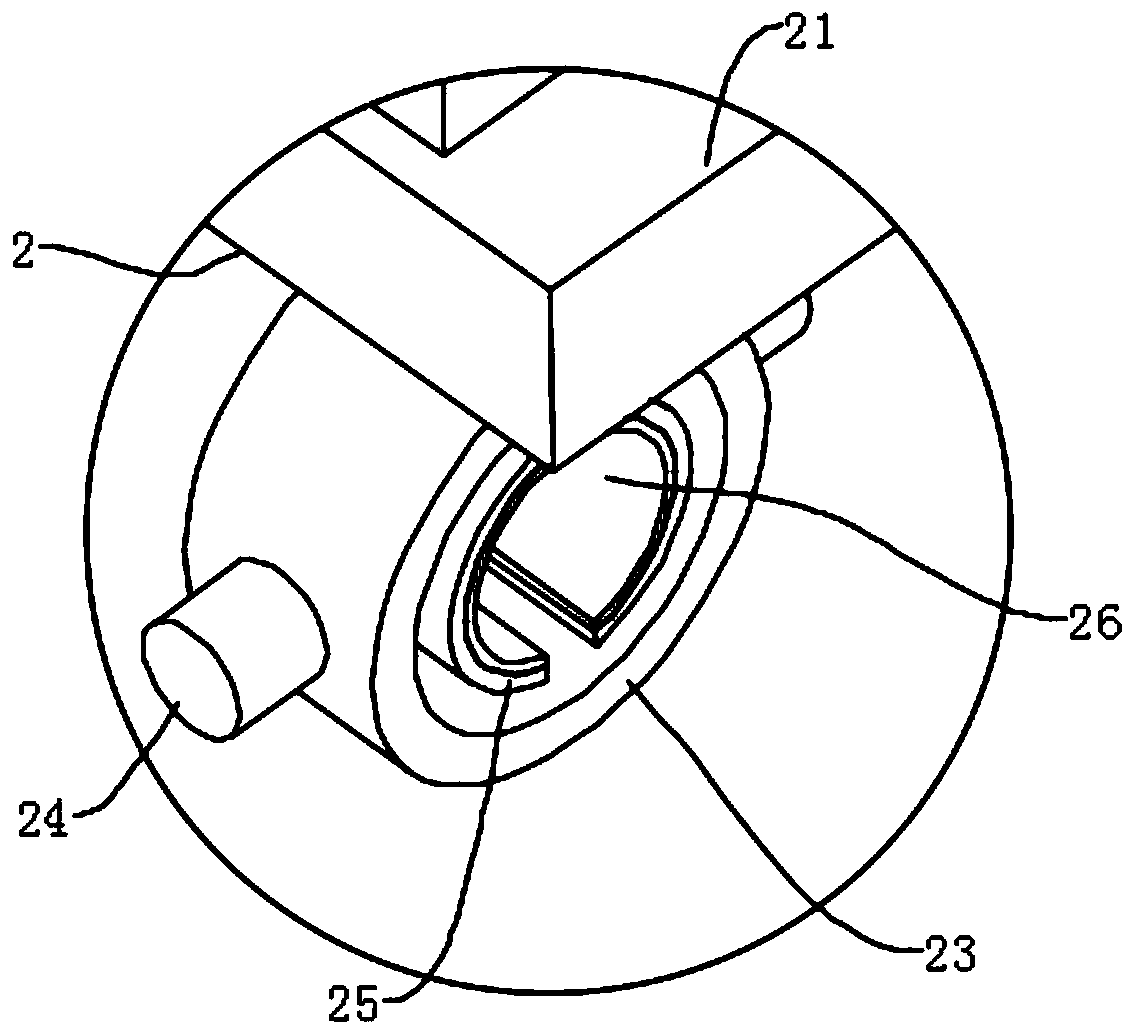

[0049] A grabbing mechanism 2 for grabbing the pipes injected by the injection molding machine 1;

[0050] A displacement assembly 3 for carrying the grasping mechanism 2 and the displacement of the pipe;

[0051] A first transport assembly 4 for placing and transporting pipes;

[0052] A cleaning assembly 5 arranged on the first transportation assembly 4 for cleaning the pipe;

[0053] A cutting assembly 6 with an adjustable cutting height arranged on the end side of the first transportation assembly 4;

[0054] A positioning assembly 7 for maintaining the cutting position of the pipe;

[0055] The second transport component 8 for transporting the finished cut pipe;

[0056] And a transfer assembly 9 for transferring the cut pipe to the second transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com